How to use heat sinks to extend the lifespan of ASIC mining equipment?

February 27, 2025

How to Use Heat Sinks to Extend the Lifespan of ASIC Mining Equipment?

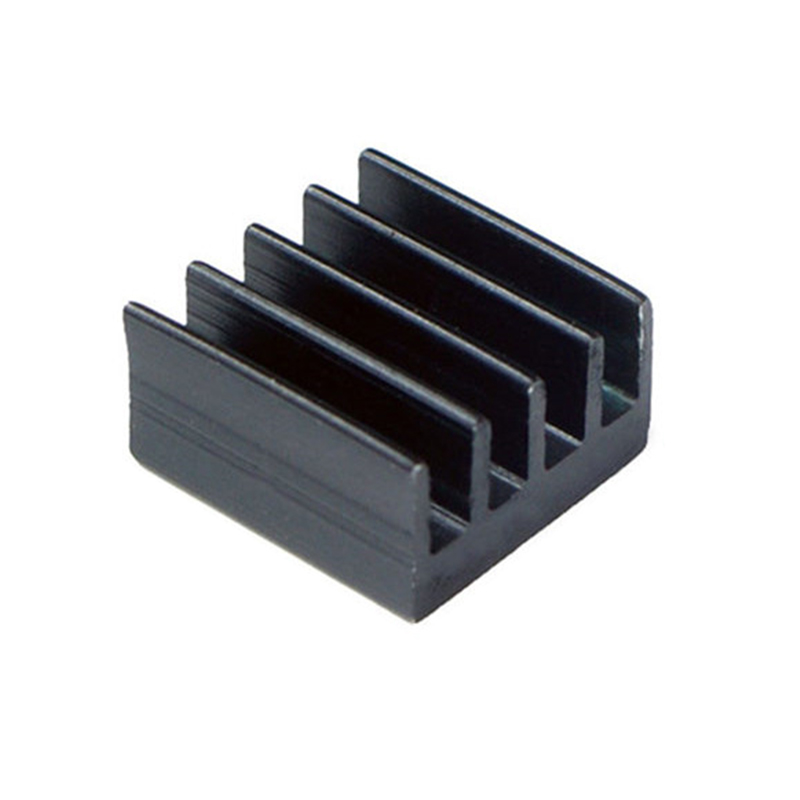

Cryptocurrency mining has evolved into a highly competitive and resource-intensive industry, where the efficiency and longevity of mining equipment are paramount. ASIC (Application-Specific Integrated Circuit) miners, the backbone of modern mining operations, are particularly sensitive to heat, which can significantly impact their performance and lifespan. This article explores how precision-engineered heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, can effectively manage thermal loads and extend the operational life of ASIC mining equipment.

The Critical Role of Heat Sinks in ASIC Mining

ASIC miners are designed to perform complex cryptographic calculations at unprecedented speeds. However, this high computational power comes at a cost: substantial heat generation. Without proper thermal management, the excessive heat can lead to thermal throttling, reduced efficiency, and ultimately, hardware failure. Heat sinks play a pivotal role in dissipating this heat, ensuring that the miners operate within their optimal temperature range.

Product Introduction: Precision-Engineered Heat Sinks for ASIC Miners

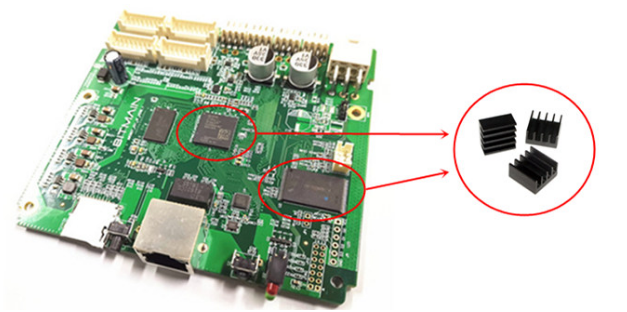

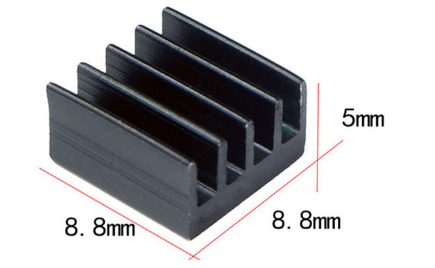

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution specifically designed for ASIC mining control boards. Its compact dimensions and lightweight design (0.01 KG) make it an ideal choice for modern mining rigs, where space and weight are critical considerations. Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction that maximizes thermal dissipation efficiency.

Technical Architecture and Thermal Interface Integration

The heat sink’s design incorporates advanced thermal engineering principles to facilitate rapid heat transfer from critical components, such as CPUs and power management chips on mining control boards. The use of a specialized thermal interface material (TIM) layer further enhances the system’s thermal transfer efficiency. This thermally conductive silica gel ensures optimal thermal conductivity between the heat-generating components and the heat sink surface, creating an efficient thermal pathway for heat dissipation.

Product Advantages: Enhancing ASIC Miner Performance and Longevity

Optimized Spatial Efficiency

One of the standout features of the 8.8mm × 8.8mm × 5mm heat sink is its optimized spatial efficiency. Engineered with precise dimensional specifications, it maximizes cooling performance while minimizing the spatial footprint within mining rigs. This careful balance ensures that the heat sink can be seamlessly integrated into existing setups without compromising on thermal management capabilities.

Advanced Thermal Management

The heat sink delivers superior temperature control at critical device nodes, maintaining optimal operating conditions well within specified thermal limits. This precise thermal regulation helps prevent thermal throttling, a common issue in high-performance mining operations. By keeping the temperature in check, the heat sink ensures that the ASIC miner operates at peak efficiency, thereby extending its lifespan.

Enhanced Power Efficiency

Efficient heat dissipation plays a crucial role in reducing thermal-induced power losses. The 8.8mm × 8.8mm × 5mm heat sink significantly lowers these losses, resulting in improved overall system efficiency and reduced operating costs. The optimized design helps maintain consistent power delivery to critical mining components, ensuring that the miner performs at its best without unnecessary energy waste.

Environmental Control Excellence

The heat sink’s multi-piece design facilitates improved air circulation and heat displacement, creating an optimized microenvironment around critical components. This strategic airflow management ensures that heat is evenly distributed and efficiently removed from the system, further enhancing the miner’s performance and longevity.

Durability-Focused Design

Constructed from premium aluminum alloy, the heat sink is designed to withstand the rigors of continuous high-temperature conditions. Its robust design ensures long-term reliability and consistent thermal performance throughout extended mining operations. This durability-focused approach minimizes the risk of hardware failure, providing mining operators with peace of mind and reducing maintenance costs.

Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency from components to the heat sink surface. This optimization ensures consistent thermal conductivity across the entire contact area, further enhancing the heat sink’s effectiveness in managing thermal loads.

Installation Versatility

Designed for compatibility with various control board configurations, the 8.8mm × 8.8mm × 5mm heat sink ensures optimal thermal contact across different mining hardware setups. This installation versatility makes it a versatile solution for a wide range of ASIC miners, allowing mining operators to standardize their thermal management systems across multiple rigs.

Practical Applications: Real-World Benefits for Mining Operators

Extending ASIC Miner Lifespan

By effectively managing thermal loads, the 8.8mm × 8.8mm × 5mm heat sink helps extend the lifespan of ASIC miners. Consistent temperature control prevents thermal-induced degradation, reducing the frequency of hardware replacements and lowering overall operational costs. For mining operators, this translates to a higher return on investment (ROI) and improved profitability.

Improving Mining Efficiency

Efficient thermal management directly impacts the performance of ASIC miners. By maintaining optimal operating temperatures, the heat sink ensures that miners operate at peak efficiency, maximizing hash rates and reducing the likelihood of downtime. This improved efficiency is crucial in a competitive mining environment, where even slight performance gains can make a significant difference.

Reducing Energy Consumption

The heat sink’s ability to reduce thermal-induced power losses contributes to lower energy consumption. For large-scale mining operations, this can result in substantial cost savings over time. By optimizing power efficiency, the heat sink helps mining operators reduce their environmental footprint while maintaining high-performance standards.

Enhancing System Reliability

The durability-focused design of the heat sink ensures that it can withstand the demanding conditions of continuous mining operations. This enhanced system reliability minimizes the risk of unexpected hardware failures, reducing downtime and maintenance requirements. For mining operators, this translates to more consistent and predictable mining output.

Conclusion: A Game-Changer for ASIC Mining Operations

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents a significant advancement in thermal management for ASIC mining equipment. Its precision-engineered design, advanced thermal management capabilities, and durability-focused construction make it an indispensable component for modern mining rigs. By effectively managing thermal loads, this heat sink extends the lifespan of ASIC miners, improves mining efficiency, reduces energy consumption, and enhances system reliability.

For mining operators looking to optimize their operations and maximize their ROI, investing in high-quality heat sinks like the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a strategic move. Its practical benefits and real-world applications make it a game-changer in the competitive world of cryptocurrency mining. By ensuring that their mining equipment operates within optimal temperature ranges, operators can achieve sustained performance and long-term profitability in this dynamic industry.