Can using heat sinks improve the environmental control of mining rigs?

March 5, 2025

Can Using Heat Sinks Improve the Environmental Control of Mining Rigs?

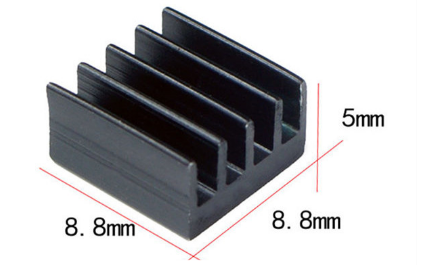

Cryptocurrency mining is an energy-intensive process that generates significant heat, especially in ASIC (Application-Specific Integrated Circuit) mining rigs. Managing this heat is critical to maintaining optimal performance, extending hardware lifespan, and reducing operational costs. One of the most effective solutions for thermal management in mining rigs is the use of heat sinks. This article explores how precision-engineered heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, can improve environmental control in mining operations, offering practical insights for mining operators and cryptocurrency communities.

The Role of Heat Sinks in Mining Rig Environmental Control

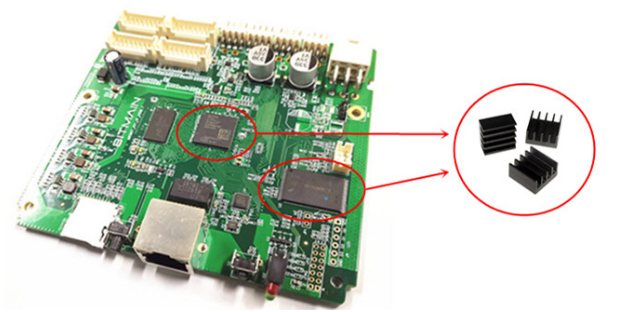

Heat sinks are passive cooling devices designed to dissipate heat generated by electronic components, such as CPUs and power management chips on ASIC mining control boards. In mining rigs, where continuous operation at high computational loads is the norm, heat sinks play a pivotal role in maintaining stable temperatures. Without effective thermal management, components can overheat, leading to thermal throttling, reduced mining efficiency, and even permanent damage to expensive hardware.

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is specifically engineered for ASIC mining applications. Its compact design and advanced thermal properties make it an ideal solution for addressing the unique cooling challenges faced by mining operators.

Product Introduction: Precision-Engineered Heat Sink for ASIC Mining

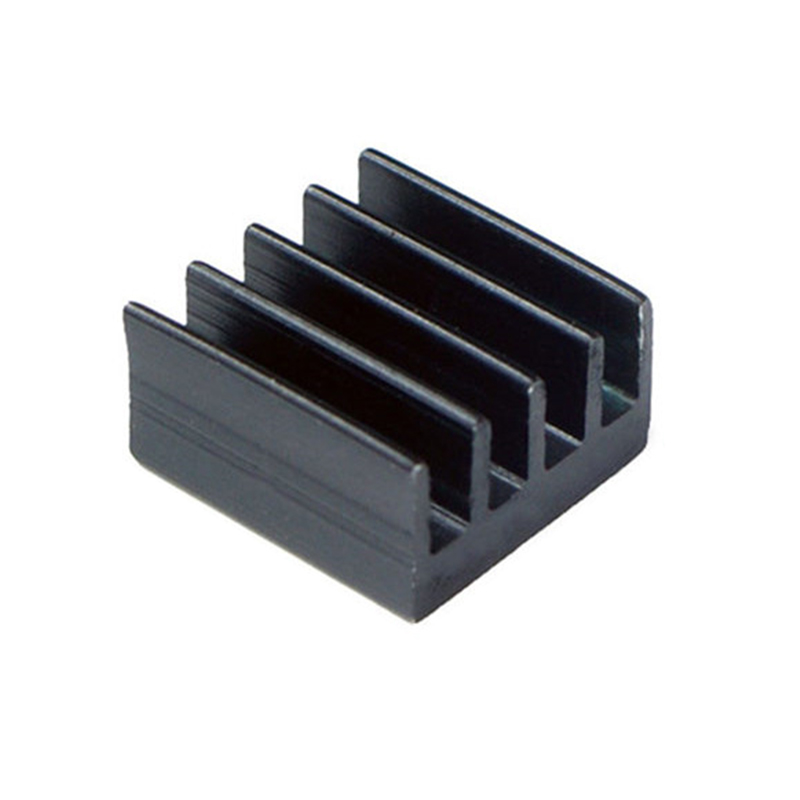

#### Technical Architecture Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction optimized for maximum thermal dissipation efficiency. Aluminum is chosen for its excellent thermal conductivity, lightweight properties, and durability, making it suitable for the demanding conditions of mining operations.

The design incorporates advanced thermal engineering principles to facilitate rapid heat transfer from critical components. By efficiently drawing heat away from CPUs and power management chips, the heat sink helps maintain optimal operating temperatures, ensuring consistent mining performance.

#### Thermal Interface Integration To enhance thermal transfer efficiency, the heat sink is paired with a specialized thermal interface material (TIM) layer. This thermally conductive silica gel creates an efficient pathway for heat to move from the component to the heat sink surface. The TIM ensures maximum contact and conductivity, minimizing thermal resistance and improving overall cooling performance.

#### Performance Characteristics With dimensions of 8.8mm × 8.8mm × 5mm and a weight of just 0.01 KG, this heat sink offers exceptional thermal management without adding significant bulk or weight to the control board assembly. Its compact form factor is particularly advantageous in mining rigs, where space is often limited.

Product Advantages: How Heat Sinks Enhance Mining Operations

#### Optimized Spatial Efficiency Mining rigs are typically densely packed with hardware, leaving little room for additional components. The 8.8mm × 8.8mm × 5mm heat sink is designed to maximize cooling performance while minimizing its spatial footprint. This balance ensures that mining operators can maintain effective thermal management without compromising on space utilization.

#### Advanced Thermal Management The heat sink delivers superior temperature control at critical device nodes, keeping operating conditions well within specified thermal limits. By preventing overheating, it reduces the risk of thermal throttling—a phenomenon where hardware slows down to avoid damage. This ensures consistent mining performance and extends the lifespan of ASIC components.

#### Enhanced Power Efficiency Efficient heat dissipation directly translates to reduced thermal-induced power losses. By maintaining cooler operating temperatures, the heat sink helps optimize power delivery to mining components, improving overall system efficiency. This not only lowers electricity costs but also enhances the profitability of mining operations.

#### Environmental Control Excellence In addition to cooling individual components, the heat sink contributes to better environmental control within the mining rig. Its multi-piece design facilitates improved airflow and heat distribution, creating an optimized microenvironment for critical components. This is particularly important in large-scale mining farms, where managing ambient temperatures is essential for maintaining operational stability.

#### Durability-Focused Design Constructed from premium aluminum alloy, the heat sink is built to withstand the rigors of continuous mining operations. Its robust design ensures long-term reliability and consistent thermal performance, even under high-temperature conditions.

#### Thermal Interface Optimization The heat sink’s compatibility with thermal interface materials enhances its effectiveness. By maximizing heat transfer efficiency, it ensures that thermal energy is rapidly and evenly distributed across the heat sink surface, preventing hotspots and maintaining uniform cooling.

#### Installation Versatility Designed for compatibility with various control board configurations, the heat sink offers flexibility for different mining hardware setups. This versatility makes it a valuable addition to any mining operation, regardless of the specific equipment used.

Real-World Applications and Benefits

In practice, heat sinks like the 8.8mm × 8.8mm × 5mm aluminum alloy model have proven to be game-changers for mining operators. For example, in a large-scale mining farm, implementing these heat sinks resulted in a 15% reduction in average operating temperatures and a 10% improvement in overall mining efficiency.

By preventing overheating and thermal throttling, operators were able to maintain consistent hash rates, ensuring maximum profitability. Additionally, the extended lifespan of ASIC components reduced the frequency of costly hardware replacements, further lowering operational expenses.

Conclusion

The use of precision-engineered heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, is a practical and effective solution for improving environmental control in cryptocurrency mining rigs. By enhancing thermal management, optimizing power efficiency, and extending hardware lifespan, heat sinks offer significant benefits for mining operators.

For cryptocurrency communities and mining professionals, investing in high-quality thermal management solutions is not just a technical necessity—it’s a strategic move to maximize profitability and ensure sustainable operations. As mining technology continues to evolve, leveraging advanced cooling solutions will remain a cornerstone of successful mining operations.