How does thermal interface material improve heat sink efficiency for mining hardware?

March 11, 2025

How Does Thermal Interface Material Improve Heat Sink Efficiency for Mining Hardware?

Cryptocurrency mining hardware, particularly ASIC miners, operates under extreme conditions where thermal management is crucial for optimal performance and longevity. One of the most critical components in maintaining efficient heat dissipation is the thermal interface material (TIM). When paired with precision-engineered heat sinks, TIM plays a pivotal role in ensuring that mining hardware remains cool, stable, and efficient. In this article, we’ll explore how thermal interface materials enhance heat sink efficiency, why they are indispensable for mining operations, and how they contribute to the overall success of your mining setup.

The Role of Thermal Interface Materials in Mining Hardware

At the heart of any mining operation lies the ASIC miner, a specialized device designed to solve complex cryptographic puzzles. These devices generate significant heat due to their high computational workload. Without effective thermal management, the heat can lead to thermal throttling, reduced hash rates, and even permanent damage to the hardware.

This is where thermal interface materials come into play. TIMs are specially engineered substances applied between the heat-generating components (such as CPUs or power management chips) and the heat sink. Their primary function is to fill microscopic air gaps between these surfaces, ensuring optimal thermal conductivity and facilitating efficient heat transfer.

In the context of mining hardware, TIMs are particularly important because they help maintain consistent temperatures across critical components, ensuring stable operation and preventing thermal-induced failures. When combined with a high-performance heat sink, TIMs create a seamless thermal pathway that maximizes cooling efficiency.

Precision-Engineered Heat Sinks for ASIC Mining Hardware

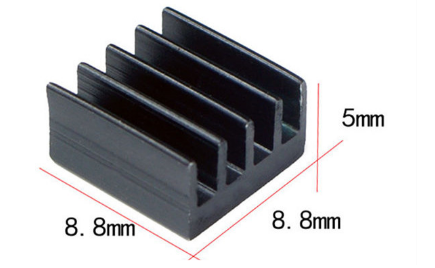

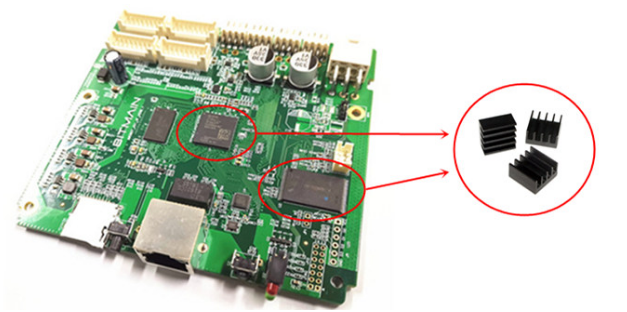

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a prime example of a thermal management solution designed specifically for ASIC mining control boards. This compact yet powerful heat sink is crafted from high-grade aluminum alloy, known for its excellent thermal conductivity and lightweight properties.

Key features of this heat sink include:

- Optimized Spatial Efficiency: Its compact design ensures it fits seamlessly into densely packed mining rigs without compromising on cooling performance.

- Advanced Thermal Management: The multi-piece construction and strategic airflow design facilitate rapid heat dissipation, keeping critical components within safe operating temperatures.

- Durability-Focused Design: Built to withstand the rigors of continuous mining operations, this heat sink maintains its structural integrity even under prolonged high-temperature conditions.

However, the true potential of this heat sink is unlocked when paired with the right thermal interface material.

How Thermal Interface Materials Enhance Heat Sink Efficiency

Thermal interface materials act as the bridge between the heat-generating components and the heat sink. Here’s how they improve heat sink efficiency in mining hardware:

1. Eliminating Air Gaps

Air is a poor conductor of heat, and even the smallest air gaps between a component and a heat sink can significantly hinder thermal transfer. TIMs fill these gaps, ensuring maximum contact between surfaces and enhancing heat conduction.

2. Optimizing Thermal Conductivity

High-quality TIMs, such as thermally conductive silica gel, are specifically formulated to provide excellent thermal conductivity. This ensures that heat is efficiently transferred from the component to the heat sink, where it can be dissipated into the surrounding environment.

3. Preventing Hot Spots

By ensuring uniform thermal conductivity across the entire contact area, TIMs help prevent hot spots that can lead to localized overheating and component failure. This is especially critical in mining hardware, where consistent performance is essential.

4. Enhancing Longevity

Effective thermal management reduces the strain on mining hardware, extending its operational lifespan. By keeping temperatures within safe limits, TIMs help prevent thermal degradation and ensure that your equipment remains reliable over time.

5. Improving Power Efficiency

Overheating can lead to increased power consumption and reduced efficiency. By maintaining optimal temperatures, TIMs contribute to lower power losses and improved overall system efficiency, ultimately reducing operating costs.

Real-World Applications in Cryptocurrency Mining

In a typical ASIC mining setup, the control board’s CPUs and power management chips are among the most heat-intensive components. Without proper cooling, these components can quickly reach critical temperatures, leading to performance degradation or failure.

By integrating a high-performance heat sink with a specialized thermal interface material, mining operators can achieve:

- Consistent Hash Rates: Stable temperatures prevent thermal throttling, ensuring that the miner operates at its full computational capacity.

- Reduced Downtime: Effective cooling minimizes the risk of hardware failures, reducing the need for costly repairs or replacements.

- Lower Operating Costs: Improved thermal efficiency translates to reduced power consumption, resulting in significant cost savings over time.

- Extended Hardware Lifespan: By preventing thermal-induced wear and tear, TIMs and heat sinks help maximize the return on investment for mining equipment.

Selecting the Right Thermal Interface Material

Not all TIMs are created equal, and selecting the right one for your mining hardware is crucial. Here are some factors to consider:

- Thermal Conductivity: Look for TIMs with high thermal conductivity ratings to ensure efficient heat transfer.

- Ease of Application: Some TIMs come in pre-applied pads, while others require manual application. Choose a format that suits your installation process.

- Durability: Ensure the TIM can withstand the high temperatures and continuous operation typical of mining environments.

- Compatibility: Verify that the TIM is compatible with both your heat sink and the components it will be applied to.

For the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, a thermally conductive silica gel TIM is an excellent choice. This material provides superior thermal conductivity, is easy to apply, and maintains its performance over extended periods.

Installation Best Practices

To maximize the effectiveness of your heat sink and TIM, follow these installation tips:

- Clean Surfaces Thoroughly: Remove any dust, grease, or old TIM residue from the component and heat sink surfaces to ensure optimal contact.

- Apply TIM Evenly: Use the recommended amount of TIM and spread it evenly across the surface. Avoid over-application, as excess material can hinder heat transfer.

- Secure the Heat Snk Properly: Ensure the heat sink is firmly attached to the component to maintain consistent pressure and contact.

- Monitor Temperatures: After installation, monitor the component temperatures to verify that the cooling solution is performing as expected.

Conclusion: The Synergy of Heat Sinks and Thermal Interface Materials

In the demanding world of cryptocurrency mining, effective thermal management is non-negotiable. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, when paired with a high-quality thermal interface material, represents a powerful solution for maintaining optimal temperatures in ASIC mining hardware. By eliminating air gaps, optimizing thermal conductivity, and preventing hot spots, TIMs enhance the efficiency of heat sinks, ensuring stable performance, extended hardware lifespan, and reduced operating costs.

For mining operators looking to maximize their ROI and safeguard their investments, integrating these advanced thermal management solutions is a smart and practical choice. With the right combination of heat sinks and TIMs, you can keep your mining hardware running cool, efficient, and reliable—even under the most challenging conditions.