What are the maintenance requirements for Iceriver KS5L/KS5M water cooling system?

March 13, 2025

What are the Maintenance Requirements for the Iceriver KS5L/KS5M Water Cooling System?

The Iceriver KS5L/KS5M water cooling plate kit is a game-changer for high-performance ASIC mining operations, offering advanced thermal management solutions designed to optimize the efficiency and longevity of Bitmain KS5L and KS5M miners. As with any sophisticated cooling system, proper maintenance is crucial to ensure sustained performance and reliability. This article delves into the maintenance requirements of the Iceriver KS5L/KS5M water cooling system, providing practical insights and operational tips for mining operators.

Understanding the Iceriver KS5L/KS5M Water Cooling System

Before diving into maintenance specifics, it’s essential to understand the key components and features of the Iceriver KS5L/KS5M water cooling system:

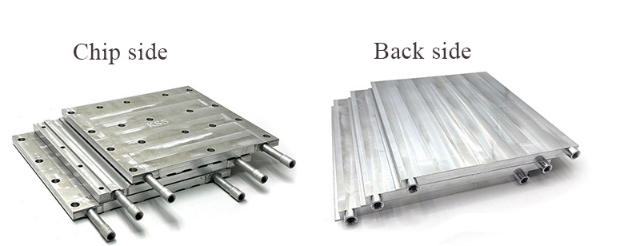

- Triple Integrated Aluminum Water-Cooling Plates: These plates are precision-engineered to maximize heat dissipation from the hash boards, ensuring optimal operating temperatures.

- Dual Water Separators: This configuration optimizes coolant distribution, reducing water pipe congestion and enhancing system efficiency.

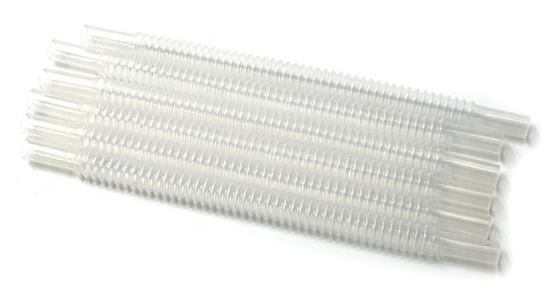

- Twelve Corrugated Bellows: Designed for smooth coolant circulation, these bellows accommodate thermal expansion and contraction, maintaining consistent temperature control.

- Quick-Connect System: Featuring 26 precision connectors, this system ensures leak-free operation and simplifies installation and maintenance.

- Specialized Cover Plate: Provides environmental protection and secures the water distribution components.

Each component is designed to work in harmony, delivering superior thermal management and long-term durability. However, regular maintenance is vital to keep the system functioning at its best.

Maintenance Requirements for the Iceriver KS5L/KS5M Water Cooling System

1. Coolant Quality and Monitoring

The coolant is the lifeblood of any water cooling system. For the Iceriver KS5L/KS5M, maintaining the quality of the coolant is paramount:

- Use Recommended Coolant: Always use the coolant specified by the manufacturer. Using substandard or incompatible coolant can lead to corrosion, blockages, or reduced cooling efficiency.

- Regular Inspection: Monitor the coolant for signs of contamination, such as discoloration or sediment buildup. Contaminated coolant can impair heat transfer and damage internal components.

- Coolant Replacement: Replace the coolant at regular intervals, typically every 6–12 months, depending on usage and environmental conditions. Follow the manufacturer’s guidelines for replacement frequency.

2. Checking for Leaks

The quick-connect system is designed to eliminate leaks, but periodic checks are still necessary:

- Visual Inspections: Regularly inspect all connectors, hoses, and fittings for signs of moisture or corrosion. Address any leaks immediately to prevent coolant loss and potential damage to the mining equipment.

- Pressure Testing: Perform pressure tests periodically to ensure the integrity of the cooling system. This is especially important after installation or major maintenance work.

3. Cleaning the Cooling Plates

The aluminum water-cooling plates are critical for heat dissipation. Keeping them clean ensures optimal performance:

- Dust and Debris Removal: Mining environments are often dusty, so regularly clean the cooling plates using compressed air or a soft brush to remove accumulated debris.

- Corrosion Prevention: Although the plates are corrosion-resistant, inspect them for signs of oxidation or pitting. If corrosion is detected, clean the affected area and apply a protective coating if necessary.

4. Inspecting the Bellows

The corrugated bellows play a vital role in maintaining smooth coolant flow and accommodating thermal expansion:

- Flexibility Check: Ensure the bellows remain flexible and free of cracks or deformations. Damaged bellows can restrict coolant flow and compromise temperature control.

- Alignment Verification: Verify that the bellows are properly aligned and securely connected. Misaligned bellows can cause stress on the system and lead to leaks.

5. Monitoring System Performance

Regular monitoring helps identify potential issues before they escalate:

- Temperature Tracking: Use monitoring software to track the temperature of the hash boards. Sudden increases in temperature may indicate a problem with the cooling system.

- Flow Rate Measurement: Ensure the coolant flow rate remains within the recommended range. Reduced flow rates can signal blockages or pump issues.

6. Pump Maintenance

The pump is essential for circulating coolant through the system:

- Noise and Vibration Checks: Unusual noises or vibrations from the pump may indicate wear or malfunction. Address these issues promptly to avoid system failure.

- Lubrication and Cleaning: Follow the manufacturer’s guidelines for lubricating and cleaning the pump. Regular maintenance extends the pump’s lifespan and ensures reliable operation.

7. Environmental Considerations

The mining environment can impact the cooling system’s performance:

- Cleanliness: Keep the mining facility clean to minimize dust and debris that can clog the cooling system.

- Temperature Control: Maintain a stable ambient temperature to reduce the workload on the cooling system. Extreme temperatures can strain the system and reduce its efficiency.

Practical Tips for Long-Term Maintenance

- Create a Maintenance Schedule: Develop a detailed maintenance schedule that includes regular inspections, coolant replacements, and component checks. Stick to this schedule to prevent unexpected downtime.

- Keep Spare Parts on Hand: Stock essential spare parts, such as connectors, hoses, and coolant, to quickly address any issues that arise.

- Train Your Team: Ensure that your maintenance team is well-trained in the specific requirements of the Iceriver KS5L/KS5M water cooling system. Proper training minimizes the risk of errors during maintenance.

- Document Maintenance Activities: Keep detailed records of all maintenance activities, including dates, findings, and actions taken. This documentation helps track system performance and identify recurring issues.

Why Maintenance Matters

Neglecting maintenance can lead to reduced cooling efficiency, increased energy consumption, and even hardware failure. In contrast, a well-maintained Iceriver KS5L/KS5M water cooling system ensures:

- Optimal Performance: Consistent cooling maintains the miners’ efficiency, maximizing hash rates and profitability.

- Extended Hardware Lifespan: Proper thermal management reduces wear and tear on the ASICs, prolonging their operational life.

- Reduced Downtime: Regular maintenance prevents unexpected breakdowns, ensuring continuous mining operations.

Conclusion

The Iceriver KS5L/KS5M water cooling system is a powerful solution for managing the thermal demands of high-performance ASIC miners. By understanding and adhering to its maintenance requirements, mining operators can unlock the full potential of this advanced cooling system. From monitoring coolant quality to inspecting key components, proactive maintenance ensures sustained performance, reliability, and profitability in today’s competitive mining landscape. Whether you’re a seasoned operator or new to the industry, investing time and resources into maintaining your cooling system will pay dividends in the long run.