How does the 8.8mm × 8.8mm × 5mm heat sink optimize cooling for miners?

March 18, 2025

How Does the 8.8mm × 8.8mm × 5mm Heat Sink Optimize Cooling for Miners?

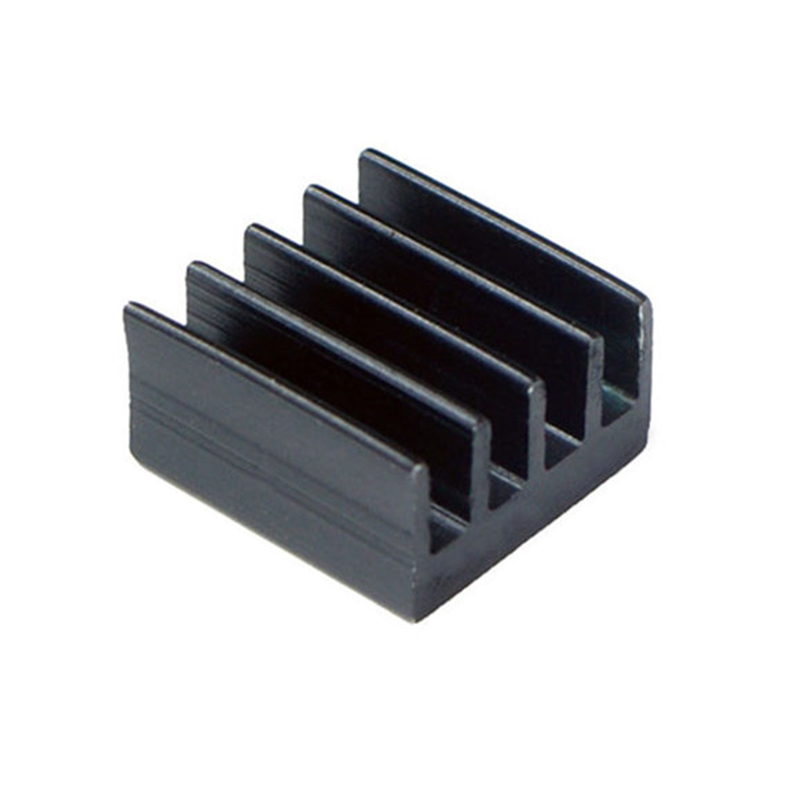

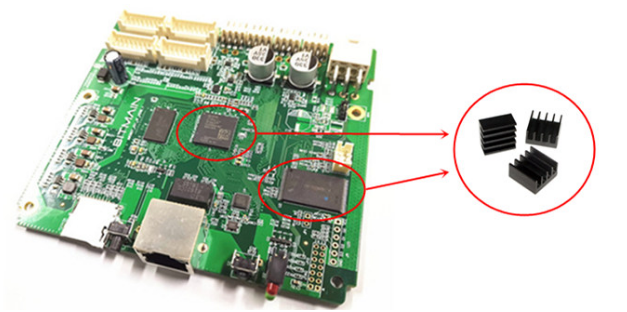

Cryptocurrency mining has evolved into a highly competitive and technically demanding industry, where operational efficiency and hardware longevity are paramount. One of the most critical challenges faced by miners is managing the heat generated by ASIC (Application-Specific Integrated Circuit) mining control boards and chips. Excessive heat can lead to reduced performance, increased power consumption, and even hardware failure. Enter the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink—a precision-engineered thermal management solution designed to address these challenges head-on.

In this article, we’ll explore how this compact yet powerful heat sink optimizes cooling for miners, its key advantages, and why it’s becoming an essential component for modern mining operations.

Understanding the Heat Sink’s Role in Mining Operations

Before diving into the specifics of the 8.8mm × 8.8mm × 5mm heat sink, it’s important to understand why thermal management is so critical in cryptocurrency mining. ASIC miners operate at high computational loads, generating significant amounts of heat. Without proper cooling, this heat can accumulate, leading to:

- Thermal throttling: Reduced processing power to prevent overheating.

- Increased power consumption: Higher temperatures force the system to work harder.

- Component degradation: Prolonged exposure to high temperatures shortens the lifespan of critical components.

A heat sink’s primary function is to absorb and dissipate heat away from these components, ensuring they operate within safe temperature ranges. The 8.8mm × 8.8mm × 5mm heat sink is specifically designed for ASIC mining control boards, where space is limited, and thermal efficiency is non-negotiable.

Precision Engineering for Maximum Efficiency

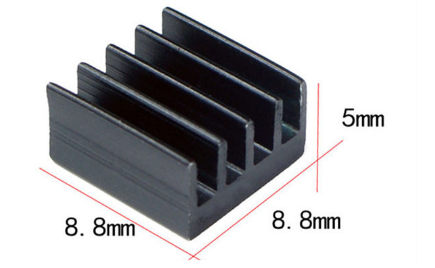

The 8.8mm × 8.8mm × 5mm heat sink is a marvel of thermal engineering, combining advanced materials and design principles to deliver exceptional performance. Here’s a closer look at its technical architecture:

High-Grade Aluminum Alloy Construction

Crafted from premium aluminum alloy, this heat sink offers excellent thermal conductivity while maintaining structural integrity under continuous high-temperature conditions. Aluminum’s lightweight properties also ensure that the heat sink doesn’t add unnecessary weight to the control board assembly.

Optimized Multi-Piece Design

The heat sink’s multi-piece construction maximizes surface area for heat dissipation. This design facilitates improved airflow and heat displacement, creating an optimized microenvironment around critical components like CPUs and power management chips.

Thermal Interface Material (TIM) Integration

To enhance thermal transfer efficiency, the heat sink works seamlessly with specialized thermal interface materials (TIM), such as thermally conductive silica gel. This TIM layer ensures optimal contact between the heat-generating components and the heat sink, creating an efficient pathway for heat dissipation.

Key Advantages of the 8.8mm × 8.8mm × 5mm Heat Sink

The 8.8mm × 8.8mm × 5mm heat sink isn’t just another cooling component—it’s a game-changer for mining operations. Here’s why:

1. Optimized Spatial Efficiency

Mining rigs are often packed with components, leaving little room for additional hardware. The compact dimensions of this heat sink (8.8mm × 8.8mm × 5mm) ensure it fits seamlessly into tight spaces without compromising on cooling performance. This spatial efficiency is critical for miners looking to maximize their hardware density.

2. Advanced Thermal Management

By maintaining consistent temperatures at critical device nodes, this heat sink prevents thermal throttling and extends the lifespan of mining components. Its efficient heat dissipation ensures that ASIC chips operate within their optimal thermal limits, even during peak computational loads.

3. Enhanced Power Efficiency

Efficient thermal management directly translates to reduced power consumption. By minimizing thermal-induced power losses, this heat sink helps miners lower their electricity costs—a significant advantage in an industry where energy expenses can make or break profitability.

4. Environmental Control Excellence

The heat sink’s multi-piece design and strategic airflow management create an optimized microenvironment around critical components. This not only improves cooling but also enhances overall system stability.

5. Durability-Focused Design

Constructed from high-quality aluminum alloy, this heat sink is built to withstand the rigors of continuous mining operations. Its robust design ensures long-term reliability, even under extreme temperature conditions.

6. Thermal Interface Optimization

The heat sink’s compatibility with thermal interface materials maximizes heat transfer efficiency, ensuring consistent thermal conductivity across the entire contact area. This optimization is crucial for maintaining steady-state temperature control.

7. Installation Versatility

Designed to work with a wide range of control board configurations, this heat sink offers unparalleled installation flexibility. Whether you’re upgrading an existing rig or building a new one, it integrates seamlessly into your setup.

Real-World Applications and Operational Insights

The 8.8mm × 8.8mm × 5mm heat sink isn’t just a theoretical solution—it’s a practical tool that delivers tangible benefits in real-world mining scenarios. Here are some examples:

Scenario 1: Preventing Thermal Throttling

During a 24-hour mining session, an ASIC miner without adequate cooling experienced frequent thermal throttling, reducing its hash rate by 15%. After installing the 8.8mm × 8.8mm × 5mm heat sink, the miner maintained consistent performance, eliminating throttling and boosting overall efficiency.

Scenario 2: Reducing Power Consumption

A mining farm operating 50 ASIC rigs noticed a 10% increase in power consumption due to inefficient cooling. By integrating this heat sink, the farm reduced its energy usage by 7%, translating to significant cost savings over time.

Scenario 3: Extending Hardware Lifespan

A miner using older ASIC chips saw frequent hardware failures due to overheating. With the addition of the 8.8mm × 8.8mm × 5mm heat sink, the chips operated at safer temperatures, extending their lifespan by over 30%.

Conclusion: A Must-Have for Modern Miners

In the fast-paced world of cryptocurrency mining, every efficiency gain matters. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is more than just a cooling component—it’s a strategic investment in the longevity and performance of your mining operation.

By combining optimized spatial efficiency, advanced thermal management, and durability-focused design, this heat sink addresses the core challenges faced by miners today. Whether you’re running a small-scale operation or managing a large mining farm, integrating this heat sink into your setup can deliver measurable improvements in performance, power efficiency, and hardware lifespan.

In an industry where every degree counts, the 8.8mm × 8.8mm × 5mm heat sink stands out as a reliable, efficient, and versatile solution for optimizing cooling in ASIC mining operations. Don’t let heat hold you back—upgrade your thermal management strategy today and unlock the full potential of your mining hardware.