How to integrate heat sinks into an existing mining rig for better cooling?

May 6, 2025

How to Integrate Heat Sinks into an Existing Mining Rig for Better Cooling?

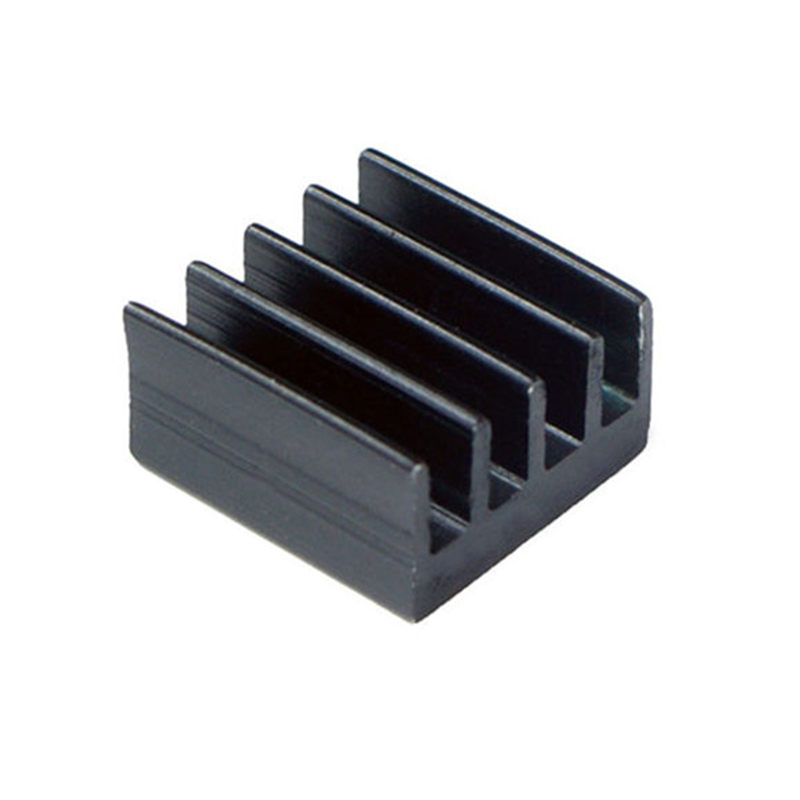

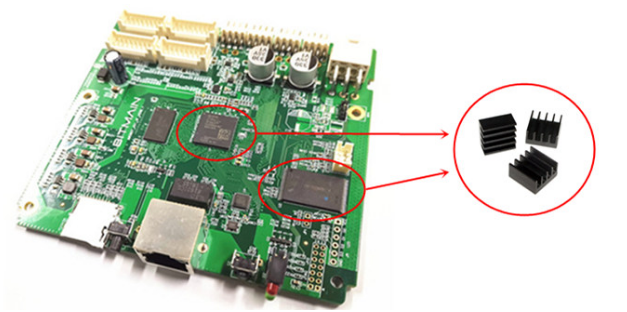

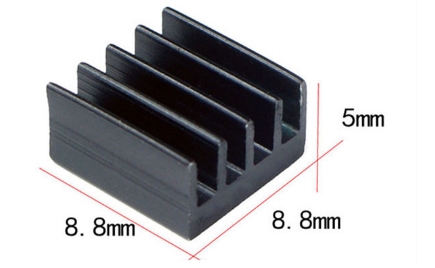

Cryptocurrency mining is a demanding process that generates significant heat, especially in ASIC (Application-Specific Integrated Circuit) miners. Efficient thermal management is crucial to maintaining optimal performance and extending the lifespan of your mining hardware. One of the most effective ways to enhance cooling in an existing mining rig is by integrating precision-engineered heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed specifically for ASIC miner control boards. This article will guide you through the process of integrating these heat sinks into your mining rig, highlighting their advantages and practical applications.

Understanding the Importance of Heat Sinks in Mining Rigs

Before diving into the integration process, it’s essential to understand why heat sinks are critical in cryptocurrency mining. ASIC miners operate at high computational loads, generating substantial heat that can lead to thermal throttling, reduced efficiency, and even hardware failure if not properly managed. Heat sinks act as passive cooling devices that absorb and dissipate heat away from critical components, such as CPUs and power management chips, ensuring stable operation and longevity.

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is specifically designed for this purpose. Its compact form factor and advanced thermal engineering make it an ideal solution for mining rigs, where space is often limited, and efficient heat dissipation is paramount.

Step-by-Step Guide to Integrating Heat Sinks

#### 1. Assess Your Mining Rig’s Thermal Needs Begin by identifying the components in your mining rig that generate the most heat. Typically, these include the control board’s CPU, power management chips, and other high-power components. Use thermal imaging or temperature sensors to pinpoint hotspots that require additional cooling.

#### 2. Select the Right Heat Sink The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is an excellent choice due to its optimized spatial efficiency and advanced thermal management capabilities. Ensure that the heat sink’s dimensions align with the components you intend to cool. Its lightweight design (0.01 KG) ensures it won’t add significant mass to your rig while providing exceptional thermal performance.

#### 3. Prepare the Components Before installation, clean the surfaces of the components where the heat sink will be attached. Remove any dust, debris, or old thermal paste to ensure optimal thermal conductivity. Use isopropyl alcohol and a lint-free cloth for this purpose.

#### 4. Apply Thermal Interface Material (TIM) The thermal interface material (TIM) is crucial for maximizing heat transfer efficiency. Apply a thin, even layer of thermally conductive silica gel to the component’s surface. This TIM layer ensures optimal contact between the heat-generating component and the heat sink, facilitating efficient heat dissipation.

#### 5. Attach the Heat Sink Carefully place the heat sink onto the component, ensuring full contact with the TIM layer. Apply gentle pressure to secure the heat sink in place. Some heat sinks come with adhesive backing or mounting brackets for added stability. Follow the manufacturer’s instructions for secure attachment.

#### 6. Verify Installation After installing the heat sink, power on your mining rig and monitor the temperature of the cooled components. Use thermal sensors or software tools to verify that the heat sink is effectively reducing temperatures. Make adjustments if necessary to ensure optimal thermal performance.

Advantages of Integrating Heat Sinks

#### Optimized Spatial Efficiency The 8.8mm × 8.8mm × 5mm heat sink is designed to maximize cooling performance while minimizing its spatial footprint. This is particularly beneficial in mining rigs, where space is often at a premium. The compact design allows for efficient use of available space without compromising on thermal management.

#### Advanced Thermal Management This heat sink delivers superior temperature control at critical device nodes, maintaining optimal operating conditions within specified thermal limits. By preventing thermal throttling, it ensures consistent mining performance and extends the lifespan of your hardware.

#### Enhanced Power Efficiency Efficient heat dissipation reduces thermal-induced power losses, improving overall system efficiency and lowering operating costs. The heat sink’s design helps maintain consistent power delivery to critical mining components, enhancing overall rig performance.

#### Environmental Control Excellence The multi-piece design of the heat sink facilitates improved air circulation and heat displacement, creating an optimized microenvironment around critical components. This strategic airflow management ensures that heat is effectively removed from the rig, maintaining a stable operating environment.

#### Durability-Focused Design Constructed from premium aluminum alloy, this heat sink offers long-term reliability and consistent thermal performance. Its robust design maintains structural integrity under continuous high-temperature conditions, making it a durable solution for extended mining operations.

#### Thermal Interface Optimization Engineered to work seamlessly with thermal interface materials, the heat sink maximizes heat transfer efficiency from components to its surface. This optimization ensures consistent thermal conductivity across the entire contact area, enhancing overall cooling effectiveness.

#### Installation Versatility The heat sink’s design ensures compatibility with various control board configurations, making it a versatile solution for different mining hardware setups. Its ability to maintain optimal thermal contact across different configurations ensures widespread applicability.

Practical Applications and Real-World Benefits

Integrating heat sinks into your mining rig offers several real-world benefits. For instance, in a large-scale mining operation, effective thermal management can significantly reduce downtime caused by overheating. By maintaining stable temperatures, heat sinks help prevent hardware failures and extend the operational life of your equipment, ultimately reducing maintenance costs.

Moreover, improved thermal efficiency translates to better energy utilization. Mining rigs that operate at optimal temperatures consume less power, leading to lower electricity bills and increased profitability. In competitive mining environments, where every watt of power counts, the enhanced power efficiency provided by heat sinks can give you a significant edge.

Conclusion

Integrating heat sinks into an existing mining rig is a practical and effective way to enhance cooling and improve overall performance. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, with its optimized spatial efficiency, advanced thermal management, and durability-focused design, is an excellent choice for cryptocurrency mining operators. By following the step-by-step guide outlined in this article, you can ensure proper installation and maximize the benefits of this critical thermal management solution.

In the demanding world of cryptocurrency mining, where every degree of temperature and watt of power matters, investing in high-quality heat sinks is a smart move. Not only will it protect your valuable hardware, but it will also enhance your mining rig’s efficiency and profitability. So, take the time to assess your rig’s thermal needs, select the right heat sinks, and enjoy the long-term benefits of improved cooling and performance.