What are the advantages of the electrolytic-plated housing in HQ2000-A01 PSU?

May 25, 2025

What Are the Advantages of the Electrolytic-Plated Housing in HQ2000-A01 PSU?

Cryptocurrency mining is a demanding industry that requires robust, reliable, and efficient equipment to ensure optimal performance and profitability. Among the critical components of any mining setup is the power supply unit (PSU), which must deliver consistent power while withstanding harsh environmental conditions. The HQ2000-A01 PSU, designed specifically for Goldshell’s Box series mining equipment, stands out as a professional-grade solution that addresses these challenges head-on. One of its most notable features is its electrolytic-plated housing, a technological advancement that significantly enhances durability, protection, and overall performance. In this article, we’ll explore the advantages of this innovative housing and how it benefits mining operators in real-world applications.

Understanding the HQ2000-A01 PSU: A Powerhouse for Mining Operations

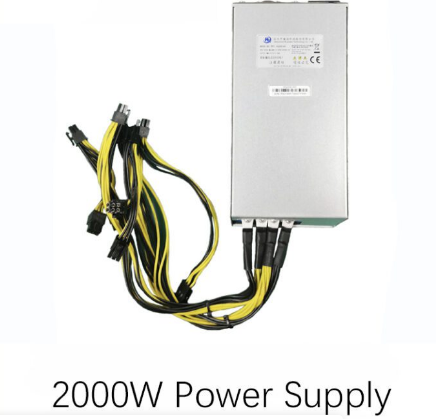

Before diving into the specifics of the electrolytic-plated housing, it’s essential to understand the broader context of the HQ2000-A01 PSU. This industrial-grade power supply is engineered to meet the rigorous demands of professional mining operations, offering a robust 2000W output capacity and a precise 12.5V output voltage with up to 160A current delivery. Its wide input voltage range (176-300VAC) ensures compatibility with various global power standards, making it a versatile choice for miners worldwide.

The PSU is specifically designed for seamless integration with Goldshell’s Box series mining equipment, including the KA Box, KD Box, HS Box, LB Box, SC Box, and CK Box models. This universal compatibility, combined with its compact form factor and advanced thermal management system, makes the HQ2000-A01 a go-to solution for miners seeking reliability and efficiency.

However, what truly sets this PSU apart is its electrolytic-plated server chassis, a feature that elevates its durability and environmental resilience to new heights. Let’s explore why this housing technology is a game-changer for mining operations.

The Role of Electrolytic-Plated Housing in Mining PSUs

In the world of cryptocurrency mining, power supplies are often subjected to extreme conditions, including high temperatures, humidity, dust, and metallic particles. Traditional PSU housings may struggle to withstand these challenges, leading to reduced lifespan, performance degradation, or even catastrophic failures. The electrolytic-plated housing in the HQ2000-A01 addresses these issues by providing superior protection and durability.

1. Enhanced Durability for Long-Term Reliability

The electrolytic plating process involves coating the housing with a thin layer of metal, typically through an electrochemical reaction. This creates a robust barrier that protects the internal components from physical damage, corrosion, and wear. For mining operators, this translates to a PSU that can withstand the rigors of continuous operation without compromising performance.

In practical terms, this means fewer maintenance requirements and a longer operational lifespan. For example, in high-altitude or desert environments where temperature fluctuations and abrasive particles are common, the electrolytic-plated housing ensures that the PSU remains intact and functional. This durability is particularly valuable for large-scale mining operations, where downtime can result in significant financial losses.

2. Superior Resistance to Environmental Factors

Mining operations often take place in challenging environments, from humid regions to dusty warehouses. The HQ2000-A01’s electrolytic-plated housing provides exceptional resistance to moisture, dust, and metallic particles, ensuring reliable performance even in adverse conditions.

For instance, in high-humidity areas, traditional PSUs may be prone to corrosion, which can lead to electrical shorts or component failure. The electrolytic plating acts as a protective shield, preventing moisture from penetrating the housing and damaging the internal circuitry. Similarly, in dusty environments, the sealed and reinforced housing keeps abrasive particles at bay, reducing the risk of overheating or mechanical wear.

3. Improved Thermal Management

Heat is one of the biggest challenges in cryptocurrency mining, as excessive temperatures can degrade performance and shorten the lifespan of equipment. The electrolytic-plated housing in the HQ2000-A01 plays a crucial role in thermal management by dissipating heat more effectively than traditional materials.

The metal plating enhances the housing’s thermal conductivity, allowing it to absorb and distribute heat evenly. This, combined with the PSU’s advanced cooling system, ensures that the unit remains within safe operating temperatures even under heavy loads. For mining operators, this means greater stability and reduced risk of thermal-related failures.

4. Professional-Grade Aesthetics and Build Quality

While functionality is paramount, the electrolytic-plated housing also contributes to the PSU’s professional-grade aesthetics. The sleek, metallic finish not only looks impressive but also reflects the unit’s high-quality construction. This attention to detail is a testament to the manufacturer’s commitment to delivering a product that meets the needs of serious mining professionals.

Real-World Applications and Benefits

The advantages of the electrolytic-plated housing in the HQ2000-A01 PSU translate into tangible benefits for mining operators. Here are a few examples of how this feature enhances real-world operations:

1. High-Altitude Mining

In high-altitude regions, where air density is lower and temperatures can fluctuate dramatically, traditional PSUs may struggle to maintain stable performance. The HQ2000-A01’s robust housing ensures that the unit remains operational, even in these challenging conditions. This makes it an ideal choice for mining farms located in mountainous areas.

2. Desert Environments

Desert mining operations face unique challenges, including extreme heat, sandstorms, and dust. The electrolytic-plated housing provides a protective barrier against these elements, ensuring that the PSU continues to function reliably. This is particularly important for remote mining sites, where equipment failures can be costly and difficult to address.

3. High-Humidity Locations

In tropical or coastal regions, high humidity can pose a significant risk to electronic equipment. The HQ2000-A01’s moisture-resistant housing prevents corrosion and electrical issues, making it a dependable choice for miners operating in these areas.

4. Large-Scale Mining Farms

For large-scale operations with hundreds or thousands of mining rigs, reliability and durability are critical. The HQ2000-A01’s electrolytic-plated housing reduces the need for frequent maintenance and replacements, helping operators maximize uptime and profitability.

Conclusion: A Game-Changer for Mining Power Supplies

The electrolytic-plated housing in the HQ2000-A01 PSU represents a significant advancement in mining power supply technology. By enhancing durability, environmental resilience, thermal management, and overall build quality, this feature ensures that the PSU can meet the demanding requirements of professional mining operations. Whether you’re running a small-scale setup or managing a large mining farm, the HQ2000-A01 offers the reliability and performance you need to stay competitive in the ever-evolving world of cryptocurrency mining.

Investing in a PSU with electrolytic-plated housing is not just about protecting your equipment—it’s about safeguarding your mining operation’s long-term success. With the HQ2000-A01, you can focus on maximizing your hash rate and profitability, knowing that your power supply is built to withstand the toughest conditions.