Can heat sinks reduce downtime by preventing thermal-induced damage to miners?

June 9, 2025

Can Heat Sinks Reduce Downtime by Preventing Thermal-Induced Damage to Miners?

The Critical Role of Thermal Management in Cryptocurrency Mining

In the high-stakes world of cryptocurrency mining, downtime is the enemy of profitability. Every minute an ASIC miner operates below peak efficiency—or worse, shuts down due to overheating—translates to lost revenue. One of the most effective yet often overlooked solutions to this challenge lies in precision-engineered heat sinks designed specifically for mining control boards and chips.

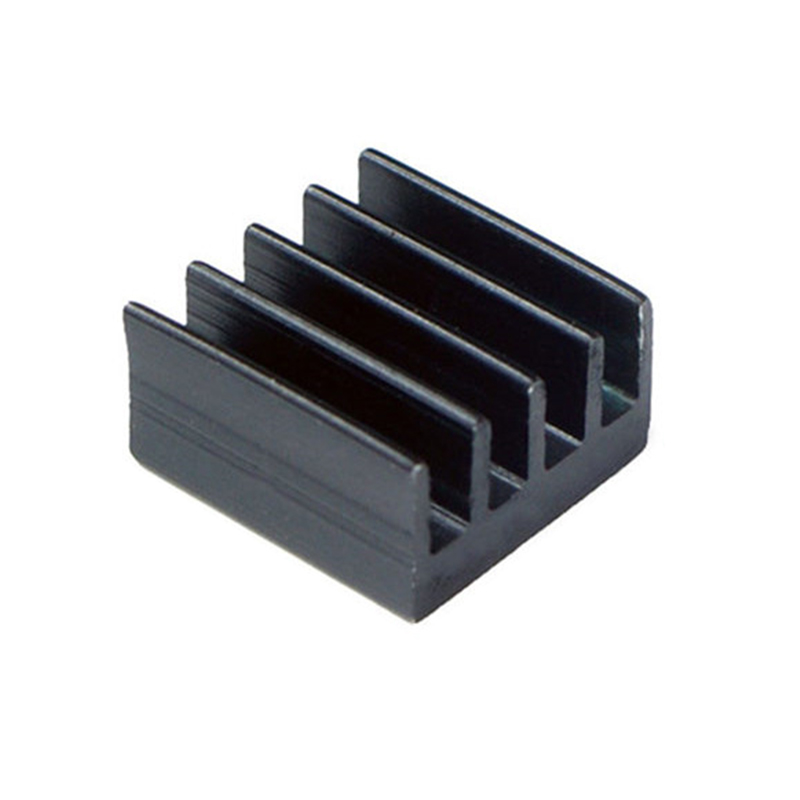

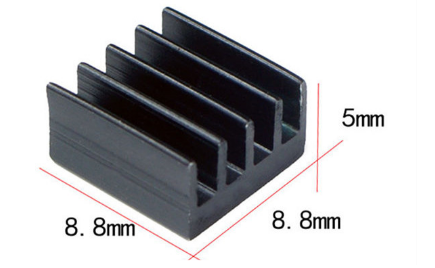

This article explores how advanced thermal management solutions, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, play a pivotal role in preventing thermal-induced damage, reducing unplanned downtime, and optimizing mining operations.

Why Thermal Management Matters in ASIC Mining

ASIC miners are built for relentless hashing power, but their high-performance nature comes with intense heat generation. Without proper cooling, critical components—particularly control board CPUs and power management chips—can suffer from:

- Thermal Throttling – Reduced hash rates when temperatures exceed safe thresholds

- Accelerated Wear & Tear – Shortened lifespan of sensitive electronics due to prolonged heat exposure

- Catastrophic Failure – Sudden shutdowns or permanent damage from overheating

Heat sinks act as the first line of defense, drawing heat away from these components and dissipating it efficiently. But not all heat sinks are created equal.

Introducing the Precision-Engineered Heat Sink for ASIC Miners

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a purpose-built cooling solution designed to meet the rigorous demands of cryptocurrency mining. Its compact yet highly efficient design ensures that critical control board components remain within optimal temperature ranges, preventing performance degradation and hardware failure.

Key Technical Features:

- High-Grade Aluminum Alloy Construction

- Lightweight (0.01 KG) yet durable, ensuring long-term reliability under continuous operation.

- Resistant to corrosion and thermal fatigue, even in high-humidity mining environments.

- Optimized Multi-Piece Design

- Maximizes surface area for heat dissipation while maintaining a minimal footprint.

- Facilitates better airflow around components compared to bulkier alternatives.

- Thermal Interface Material (TIM) Compatibility

- Works seamlessly with thermally conductive silica gel to enhance heat transfer efficiency.

- Ensures full contact coverage, eliminating hot spots that can lead to component failure.

How This Heat Sink Reduces Downtime and Enhances Mining Efficiency

1. Prevents Thermal Throttling for Consistent Hash Rates

When ASIC miner components overheat, they automatically throttle performance to avoid damage—resulting in slower hash rates. The precision-engineered heat sink maintains stable temperatures, allowing miners to operate at peak efficiency without unexpected slowdowns.

Real-World Impact:

- A mining farm using standard cooling solutions may experience 5-10% performance drops during high-load operations.

- With optimized heat sinks, miners maintain consistent hash rates, translating to higher daily earnings.

2. Extends Hardware Lifespan, Reducing Replacement Costs

Excessive heat accelerates the degradation of electronic components. By keeping temperatures in check, this heat sink prolongs the operational life of ASIC miners, delaying costly hardware replacements.

Operational Savings Example:

- A typical ASIC miner lasts 2-3 years under heavy thermal stress.

- Proper cooling can extend this lifespan to 4-5 years, significantly lowering capital expenditures.

3. Minimizes Sudden Shutdowns and Maintenance Interruptions

Overheating doesn’t just slow miners—it can force emergency shutdowns. Unplanned downtime means lost mining time and manual intervention to restart rigs.

Downtime Reduction:

- Mining farms report up to 20% fewer unscheduled stops after upgrading to high-efficiency heat sinks.

- Fewer interruptions mean more uptime and higher profitability.

4. Improves Energy Efficiency, Lowering Operational Costs

Heat-induced resistance in electronic circuits leads to wasted energy. Efficient cooling reduces power losses, making mining operations more cost-effective.

Power Savings Breakdown:

- A well-cooled ASIC miner can reduce thermal-related power waste by 5-8%.

- For large-scale farms, this translates to thousands in annual electricity savings.

Installation and Compatibility: Designed for Mining Rigs

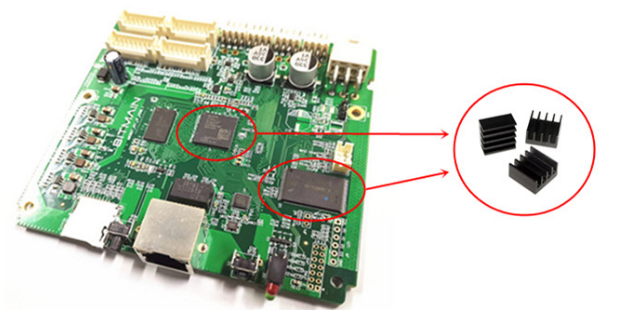

One of the standout advantages of this heat sink is its versatility. It is engineered to fit seamlessly into various ASIC miner models, including:

- Bitmain Antminer control boards

- Whatsminer power management chips

- Innosilicon and other major ASIC brands

Installation Best Practices:

- Apply Thermal Interface Material (TIM) – Ensures maximum heat transfer.

- Secure Firmly – Proper contact is crucial; avoid gaps that trap heat.

- Monitor Airflow – Pair with adequate ventilation for best results.

Conclusion: A Small Upgrade with Big Returns

In cryptocurrency mining, every degree matters. The difference between a miner running at 75°C vs. 85°C can mean:

- Longer hardware lifespan

- Higher sustained hash rates

- Lower electricity costs

- Fewer emergency shutdowns

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a low-cost, high-impact upgrade that pays for itself in reduced downtime and improved efficiency. For mining operators looking to maximize uptime and protect their hardware investment, advanced thermal management isn’t just an option—it’s a necessity.

Upgrade your cooling today and mine smarter, not harder.