What are the limitations of BM1368 Series ASIC Chip Tester for chip diagnostics?

July 1, 2025

What Are the Limitations of the BM1368 Series ASIC Chip Tester for Chip Diagnostics?

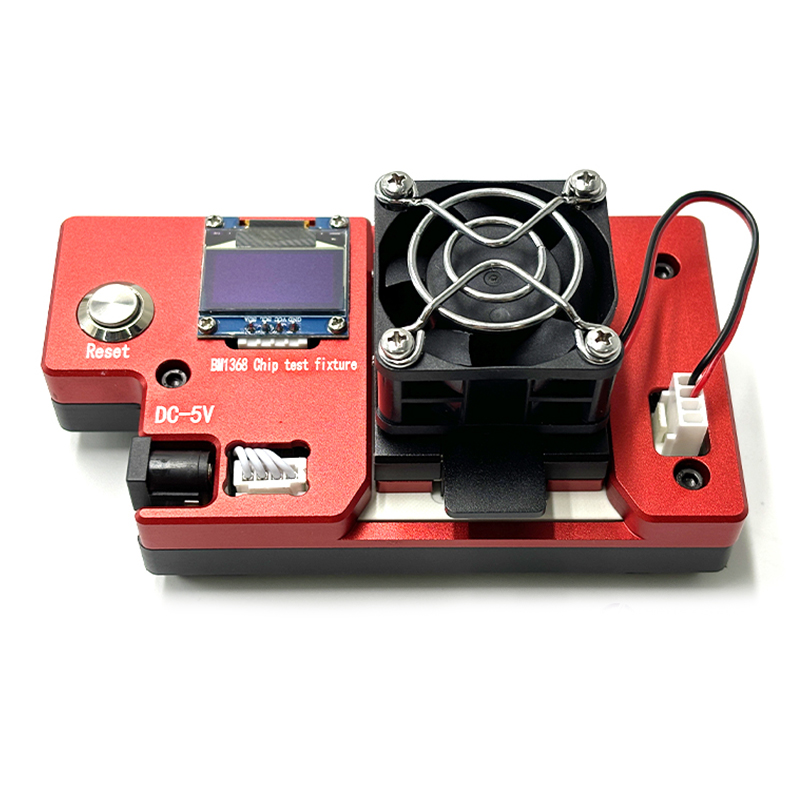

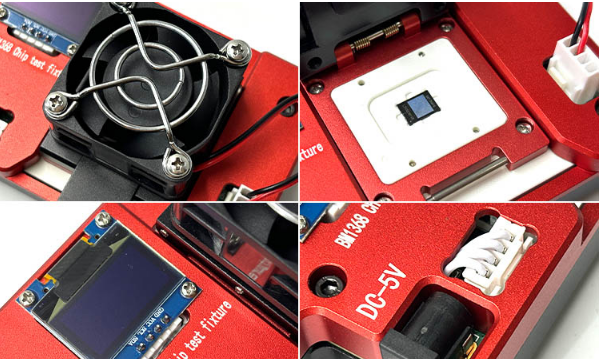

The BM1368 Series ASIC Chip Tester has emerged as a vital diagnostic tool for cryptocurrency mining operations, particularly for those utilizing Bitmain’s BM1368-based miners (such as the Antminer S19 series). Designed to streamline chip testing and maintenance workflows, this device offers rapid diagnostics, universal compatibility, and professional-grade accuracy—making it indispensable for mining farms, repair centers, and hardware resellers.

However, despite its advanced capabilities, the BM1368 tester is not without limitations. Understanding these constraints is crucial for operators who rely on it for chip validation, troubleshooting, and quality assurance. In this article, we explore the key limitations of the BM1368 Series ASIC Chip Tester, helping users maximize its effectiveness while recognizing scenarios where alternative solutions may be necessary.

1. Limited to BM1368 Series Chips Only

One of the most significant limitations of the BM1368 Series ASIC Chip Tester is its exclusive compatibility with the BM1368 family of chips (including BM1368PB, BM1368AA, BM1368PA, and BM1368PV variants). While this specialization ensures high accuracy for these specific chips, it also means the tester cannot be used for other ASIC models, such as:

- Older-generation chips (e.g., BM1387, BM1397)

- Competing ASIC models (e.g., Whatsminer or Canaan chips)

- Future Bitmain chips (unless explicitly supported in an updated version)

Practical Implications:

- Mining facilities using multiple ASIC models must invest in separate testers for each chip type, increasing equipment costs.

- Repair shops handling diverse hardware may find the BM1368 tester insufficient for broader diagnostics.

2. No Advanced Performance Benchmarking

While the BM1368 tester excels at basic functionality checks, it does not provide detailed performance benchmarking under real-world mining conditions. Key metrics such as:

- Hashrate consistency

- Power efficiency under load

- Thermal behavior during sustained operation

are not measured by this device.

Practical Implications:

- A chip that passes the tester’s diagnostics might still underperform when installed in a miner due to thermal throttling or voltage instability.

- Operators must still conduct full miner tests to confirm long-term stability.

3. Lack of Firmware or Software Customization

Unlike more advanced diagnostic tools, the BM1368 tester operates on fixed testing protocols without firmware or software customization options. This means:

- Users cannot adjust testing parameters for specialized scenarios (e.g., stress testing at higher voltages).

- No future firmware updates to expand compatibility or improve diagnostic depth.

Practical Implications:

- Repair specialists needing deeper diagnostics (e.g., identifying marginal chips that fail only under certain conditions) may require additional tools.

- Mining farms with unique testing requirements may find the rigid protocol limiting.

4. No Built-in Thermal Stress Testing

ASIC chips often fail due to thermal degradation over time. However, the BM1368 tester does not simulate thermal stress, meaning:

- It cannot detect chips that work fine at room temperature but malfunction under mining rig heat.

- Latent defects caused by overheating may go unnoticed until the chip is deployed.

Practical Implications:

- Technicians must rely on external methods (e.g., hot air testing) to verify thermal resilience.

- Some “repaired” chips may still fail in production environments.

5. Limited Diagnostic Depth for Partial Failures

The BM1368 tester is excellent at detecting complete chip failures, but its ability to diagnose partial malfunctions (e.g., a single core failing in a multi-core chip) is limited.

Practical Implications:

- A chip might pass the test but still contribute to lower hashrate in a miner if one of its cores is defective.

- Mining farms may need to combine the tester with miner-level diagnostics for full accuracy.

6. No Automated Logging or Data Export

For large-scale mining operations, data tracking is essential for predictive maintenance and inventory management. However, the BM1368 tester lacks:

- Automated test logs

- CSV/Excel export functionality

- Integration with fleet management software

Practical Implications:

- Technicians must manually record results, increasing the risk of errors.

- Large repair centers may need supplementary software solutions for batch testing analytics.

7. Power Supply Dependency & Stability Issues

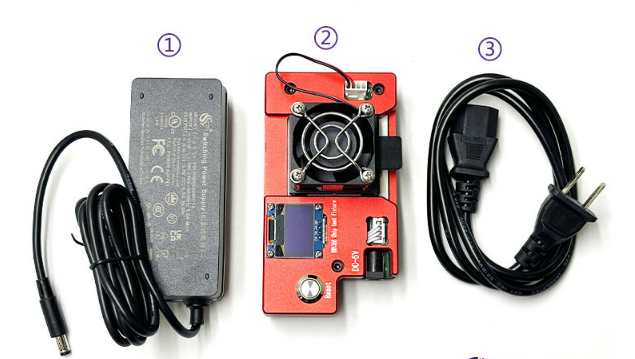

The tester requires a dedicated 5V power supply, and inconsistent power input can lead to:

- False negatives (good chips marked as faulty due to unstable voltage).

- Inconsistent test results if used with subpar adapters.

Practical Implications:

- Operators must ensure high-quality power sources to maintain testing accuracy.

- Field repairs in areas with unstable electricity may yield unreliable diagnostics.

Conclusion: Maximizing the BM1368 Tester’s Utility

Despite these limitations, the BM1368 Series ASIC Chip Tester remains a highly valuable tool for mining operators and repair specialists. Its rapid diagnostics, universal BM1368 compatibility, and professional-grade accuracy make it a worthwhile investment—but users should be aware of its constraints.

Best Practices to Overcome Limitations:

✔ Use it alongside miner-level testing for full performance validation. ✔ Combine with thermal stress tools (e.g., hot air stations) to detect heat-related failures. ✔ Maintain stable power conditions to avoid false negatives. ✔ Manually log test results if batch analysis is required.

By understanding these limitations, mining professionals can optimize their diagnostic workflows, reduce downtime, and ensure only fully functional chips enter production. While not a perfect all-in-one solution, the BM1368 tester is still an essential component of any serious ASIC maintenance toolkit.