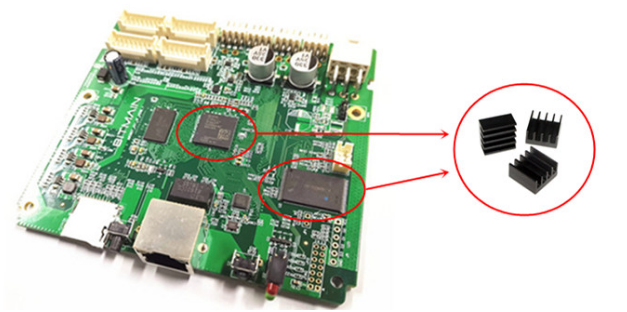

Best heat sink solutions for ASIC miner CPUs and power management chips.-ASIC miner control board/chip’s heat sinks

December 28, 2024

Title: Revolutionizing ASIC Miner Thermal Management: The Ultimate Heat Sink Solution for High-Performance Cryptocurrency Mining

In the rapidly evolving world of cryptocurrency mining, thermal management has emerged as a critical factor determining the success and longevity of mining operations. As mining hardware becomes increasingly sophisticated, the need for precise, efficient cooling solutions has never been more paramount. This article delves into a groundbreaking heat sink solution that is set to transform how we approach thermal management in ASIC mining infrastructure.

The Critical Role of Thermal Management in Cryptocurrency Mining

Cryptocurrency mining is an intense computational process that generates substantial heat. The performance and reliability of mining equipment are directly correlated with its ability to maintain optimal operating temperatures. Traditional cooling methods often fall short, leading to reduced efficiency, increased power consumption, and premature hardware failure.

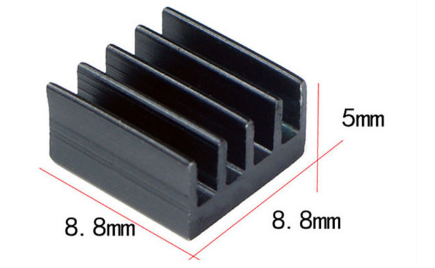

Engineering a Thermal Revolution: The 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

At the heart of this thermal management breakthrough lies a meticulously engineered heat sink that represents the pinnacle of cooling technology for ASIC mining control boards. Let’s explore the key characteristics that set this solution apart:

1. Precision-Engineered Design

The heat sink’s compact form factor (8.8mm × 8.8mm × 5mm) is a testament to advanced thermal engineering. Despite its minimal footprint, this solution delivers exceptional cooling capabilities that far exceed traditional cooling methods. The carefully calculated dimensions ensure maximum thermal dissipation without compromising valuable space within mining rigs.

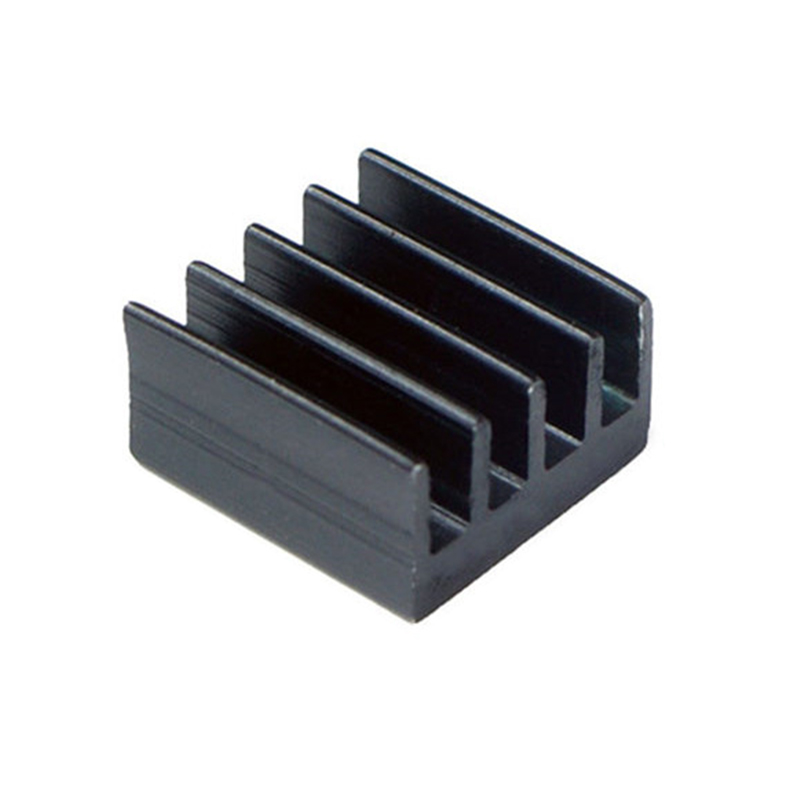

2. Advanced Material Science

Crafted from high-grade aluminum alloy, the heat sink embodies the perfect balance between lightweight construction and superior thermal conductivity. At a mere 0.01 KG, it adds negligible weight to control board assemblies while providing robust cooling performance.

Technical Deep Dive: Thermal Management Innovations

Thermal Interface Material (TIM) Integration

The heat sink’s true genius lies in its sophisticated thermal interface approach. The specialized silica gel thermal interface material creates an unprecedented thermal conductivity pathway. This innovative design ensures:

– Optimal heat transfer between components and heat sink

– Minimal thermal resistance

– Consistent temperature distribution

Performance Characteristics That Redefine Cooling Efficiency

1. Enhanced Power Efficiency

By minimizing thermal-induced power losses, the heat sink delivers a significant improvement in overall system efficiency. Mining operations can expect:

– Reduced operating costs

– Consistent power delivery

– Minimized performance degradation

2. Environmental Control Excellence

The multi-piece construction facilitates strategic airflow management, creating an optimized microenvironment around critical components. This approach ensures:

– Improved air circulation

– Efficient heat displacement

– Consistent temperature regulation

Durability: Built for Continuous Operations

The robust aluminum alloy construction is engineered to withstand the most demanding mining environments. Key durability features include:

– Long-term reliability

– Consistent thermal performance

– Structural integrity under continuous high-temperature conditions

Installation Versatility: A Universal Solution

One of the most compelling aspects of this heat sink is its wide-ranging compatibility. Designed to work seamlessly across various control board configurations, it offers:

– Widespread applicability

– Easy integration

– Optimal thermal contact across different hardware setups

Real-World Impact: Transforming Mining Operations

By addressing the critical challenges of thermal management, this heat sink solution delivers tangible benefits:

– Extended hardware lifespan

– Reduced risk of thermal throttling

– Improved overall mining efficiency

– Lower maintenance costs

Technical Specifications at a Glance

– Dimensions: 8.8mm × 8.8mm × 5mm

– Material: High-grade aluminum alloy

– Weight: 0.01 KG

– Thermal Interface: Specialized silica gel

– Compatibility: Universal ASIC mining control boards

The Future of Mining Thermal Management

As cryptocurrency mining continues to evolve, thermal management will remain a crucial factor in operational success. This heat sink represents more than just a cooling solution – it’s a strategic investment in mining infrastructure reliability and performance.

Conclusion: A Quantum Leap in Cooling Technology

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is not just an incremental improvement – it’s a quantum leap in thermal management technology. By combining precision engineering, advanced materials science, and a deep understanding of mining hardware requirements, this solution sets a new standard for cooling efficiency.

For miners seeking to maximize performance, reduce operational costs, and extend hardware longevity, this heat sink is an indispensable component of a forward-thinking mining strategy.

Invest in cutting-edge thermal management. Invest in the future of cryptocurrency mining.

|

Please feel free to contact me to assist you in resolving your issues: E-mail: Minerfixessales@gmail.com WhatsApp/WeChat:+86 15928044684

The services we offer include:

a.New and Used Miners b.Miner Accessories c.Miner Repair Courses d.Global Repair Stations e.Overclocking and Underclocking Services |

|