Can heat sinks help reduce the overall operating costs of mining rigs?

April 25, 2025

Can Heat Sinks Help Reduce the Overall Operating Costs of Mining Rigs?

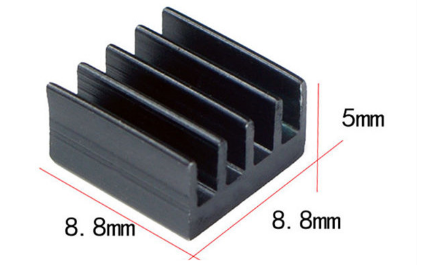

Cryptocurrency mining is an energy-intensive process that requires sophisticated hardware to solve complex algorithms. One of the most significant challenges in mining operations is managing the heat generated by ASIC miners. Excessive heat can lead to reduced efficiency, hardware degradation, and even complete system failures. This is where heat sinks come into play—a critical yet often overlooked component in mining rigs. In this article, we’ll explore how precision-engineered heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, can significantly reduce the overall operating costs of mining operations while enhancing performance and longevity.

The Role of Heat Sinks in Mining Operations

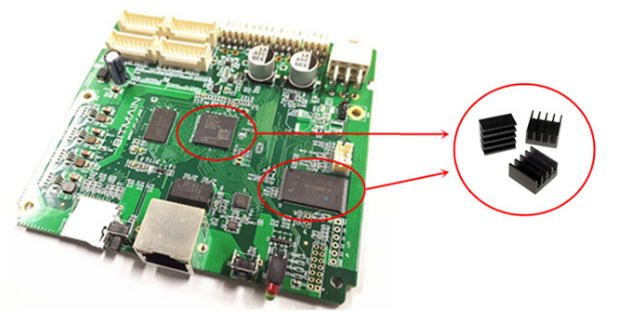

Heat sinks are thermal management solutions designed to absorb and dissipate heat away from critical components, such as CPUs and power management chips on ASIC miner control boards. In mining rigs, these components generate substantial heat due to their continuous high-performance operation. Without proper cooling, the heat can cause thermal throttling, which reduces computational efficiency and increases energy consumption. Over time, this can lead to hardware failures, necessitating costly repairs or replacements.

The precision-engineered heat sink we’re focusing on is specifically designed for ASIC mining control boards. Its compact size, lightweight construction, and advanced thermal management capabilities make it an ideal solution for addressing the demanding cooling requirements of mining operations.

Product Advantages: How Heat Sinks Optimize Mining Operations

1. Optimized Spatial Efficiency

Mining rigs are often densely packed with hardware, leaving little room for additional components. The 8.8mm × 8.8mm × 5mm heat sink is designed with precise dimensions to maximize cooling performance while occupying minimal space. This ensures that mining operators can integrate effective thermal management without compromising the layout of their rigs.

2. Advanced Thermal Management

The heat sink’s multi-piece construction and high-grade aluminum alloy material facilitate rapid heat transfer from critical components. By maintaining optimal operating temperatures, it prevents thermal throttling—a phenomenon where the system reduces performance to avoid overheating. This translates to consistent mining speeds and higher profitability.

3. Enhanced Power Efficiency

Excessive heat not only affects performance but also increases power consumption. By efficiently dissipating heat, the heat sink reduces thermal-induced power losses, leading to improved overall system efficiency. This directly lowers electricity costs, which are a significant portion of mining expenses.

4. Environmental Control Excellence

The heat sink’s design promotes strategic airflow management, creating an optimized microenvironment around critical components. This ensures that heat is evenly distributed and expelled from the system, preventing hotspots that could damage hardware.

5. Durability-Focused Design

Mining operations run 24/7, subjecting hardware to continuous stress. The heat sink’s robust construction ensures long-term reliability, maintaining consistent thermal performance even under extreme conditions. This reduces the need for frequent replacements, further lowering operational costs.

6. Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials (TIMs), such as thermally conductive silica gel. This enhances heat transfer efficiency from the components to the heat sink surface, ensuring maximum cooling effectiveness.

7. Installation Versatility

Compatible with various control board configurations, the heat sink offers flexibility for mining operators using different hardware setups. Its easy installation process ensures minimal downtime during integration.

Real-World Applications and Cost Savings

To understand the practical impact of heat sinks on mining operations, let’s consider a real-world example. A mid-sized mining farm with 100 ASIC miners experiences an average operating cost of $0.10 per kWh. Without proper cooling, each miner consumes 15% more power due to thermal inefficiencies, resulting in an additional $10,950 annually in electricity costs.

By integrating precision-engineered heat sinks, the farm reduces thermal throttling and power losses, saving up to 10% in electricity costs annually. Additionally, the extended lifespan of the hardware reduces replacement costs, which can amount to thousands of dollars over time.

Technical Insights: Why This Heat Sink Stands Out

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a product of advanced thermal engineering. Its compact form factor and lightweight design (0.01 KG) ensure that it doesn’t add significant mass to the control board assembly. The multi-piece construction maximizes surface area for heat dissipation, while the integration of TIMs ensures optimal thermal conductivity.

Moreover, the heat sink’s durability-focused design makes it resistant to wear and tear, even under continuous high-temperature conditions. This ensures that mining operators can rely on consistent performance throughout extended operations.

Conclusion: A Cost-Effective Solution for Mining Operators

In the competitive world of cryptocurrency mining, every efficiency gain translates to higher profitability. Precision-engineered heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy model, offer a practical and cost-effective solution for managing the thermal challenges of mining operations.

By optimizing spatial efficiency, enhancing power efficiency, and extending hardware lifespan, heat sinks significantly reduce the overall operating costs of mining rigs. For mining operators looking to maximize their ROI, investing in advanced thermal management solutions is not just a smart choice—it’s a necessity.

Whether you’re running a small-scale mining operation or managing a large farm, integrating high-quality heat sinks can make a measurable difference in your bottom line. As the cryptocurrency industry continues to evolve, staying ahead of the curve with innovative solutions like these will ensure sustained success in this dynamic field.