Can heat sinks help reduce the overall operating costs of mining rigs?

May 29, 2025

Can Heat Sinks Help Reduce the Overall Operating Costs of Mining Rigs?

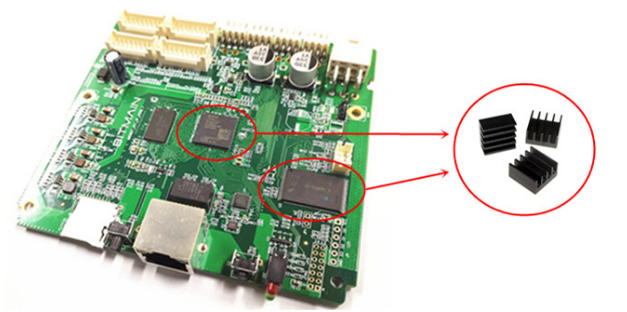

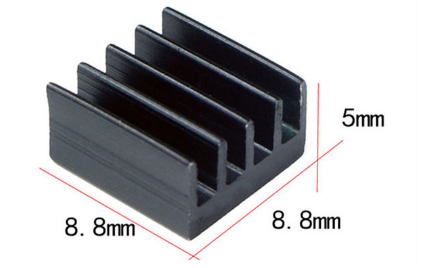

Cryptocurrency mining is an energy-intensive process that demands not only significant computational power but also effective thermal management. As mining rigs operate around the clock, the heat generated by ASIC (Application-Specific Integrated Circuit) miners can lead to performance degradation, increased power consumption, and even hardware failure if not properly managed. This is where heat sinks come into play—a seemingly simple yet critical component that can significantly impact the efficiency and cost-effectiveness of mining operations. In this article, we’ll explore how precision-engineered heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed for ASIC miner control boards, can help reduce the overall operating costs of mining rigs.

The Role of Heat Sinks in Cryptocurrency Mining

Heat sinks are passive cooling devices that dissipate heat away from critical components, such as CPUs and power management chips, to maintain optimal operating temperatures. In the context of cryptocurrency mining, where ASIC miners generate substantial heat during operation, effective thermal management is essential to ensure consistent performance and longevity of the hardware.

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is specifically designed for ASIC mining control boards, addressing the unique thermal challenges of these high-performance devices. Its compact form factor and advanced thermal engineering make it an ideal solution for mining rigs, where space is often at a premium, and efficient heat dissipation is critical.

How Heat Sinks Reduce Operating Costs

- Improved Power Efficiency

One of the most significant ways heat sinks contribute to cost savings is by improving power efficiency. When mining components overheat, they often experience thermal throttling—a process where the system reduces performance to prevent damage. This not only slows down mining operations but also increases power consumption as the system struggles to maintain stability.

The aluminum alloy heat sink, with its optimized multi-piece construction and thermal interface material (TIM), ensures rapid heat transfer and consistent temperature regulation. By preventing thermal throttling, it helps maintain peak performance while reducing unnecessary power usage, ultimately lowering electricity costs.

- Extended Hardware Lifespan

High temperatures are one of the leading causes of hardware degradation in mining rigs. Prolonged exposure to excessive heat can damage sensitive components, leading to frequent repairs or replacements. The durability-focused design of the 8.8mm × 8.8mm × 5mm heat sink, crafted from premium aluminum alloy, ensures long-term reliability even under continuous high-temperature conditions.

By protecting critical components from thermal-induced wear and tear, this heat sink extends the lifespan of mining hardware, reducing the need for costly replacements and minimizing downtime.

- Enhanced Environmental Control

Mining rigs often operate in environments where airflow and temperature management are challenging. The multi-piece design of the heat sink facilitates improved air circulation and heat displacement, creating an optimized microenvironment around critical components. This strategic airflow management not only enhances cooling efficiency but also reduces the strain on external cooling systems, such as fans or air conditioning, further lowering operational costs.

- Reduced Maintenance Requirements

Effective thermal management minimizes the risk of hardware failures and malfunctions, which can be both time-consuming and expensive to address. The heat sink’s ability to maintain steady-state temperature control ensures that mining rigs operate smoothly with fewer interruptions. This translates to reduced maintenance requirements and lower associated costs.

Key Features of the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

- Optimized Spatial Efficiency: Designed to maximize cooling performance while minimizing spatial footprint, this heat sink fits seamlessly into compact mining rig setups without compromising on thermal management.

- Advanced Thermal Management: Delivers superior temperature control at critical device nodes, preventing thermal throttling and ensuring consistent performance.

- Thermal Interface Optimization: Engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency from components to the heat sink surface.

- Installation Versatility: Compatible with various control board configurations, making it a versatile solution for different mining hardware setups.

Real-World Applications and Benefits

In practical terms, integrating the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink into mining rigs can yield tangible benefits. For example, a mining operation running 100 ASIC miners could see a significant reduction in power consumption and hardware replacement costs over time. By maintaining optimal operating temperatures, the heat sink ensures that each miner operates at peak efficiency, maximizing hash rates while minimizing energy waste.

Additionally, the heat sink’s durability-focused design makes it particularly well-suited for large-scale mining farms, where equipment is subjected to continuous use. Its ability to withstand high temperatures and maintain consistent performance reduces the likelihood of unexpected failures, allowing operators to focus on scaling their operations rather than troubleshooting hardware issues.

Conclusion

In the competitive world of cryptocurrency mining, every advantage counts. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents a cost-effective solution to one of the industry’s most pressing challenges: thermal management. By improving power efficiency, extending hardware lifespan, enhancing environmental control, and reducing maintenance requirements, this precision-engineered component can significantly lower the overall operating costs of mining rigs.

For mining operators looking to optimize their operations and maximize profitability, investing in high-quality heat sinks is not just a technical consideration—it’s a strategic decision. With its advanced thermal management capabilities and durable design, this heat sink is a valuable addition to any mining setup, ensuring that your hardware performs at its best while keeping costs in check.