Can heat sinks help with noise reduction in ASIC mining operations?

July 24, 2025

Can Heat Sinks Help with Noise Reduction in ASIC Mining Operations?

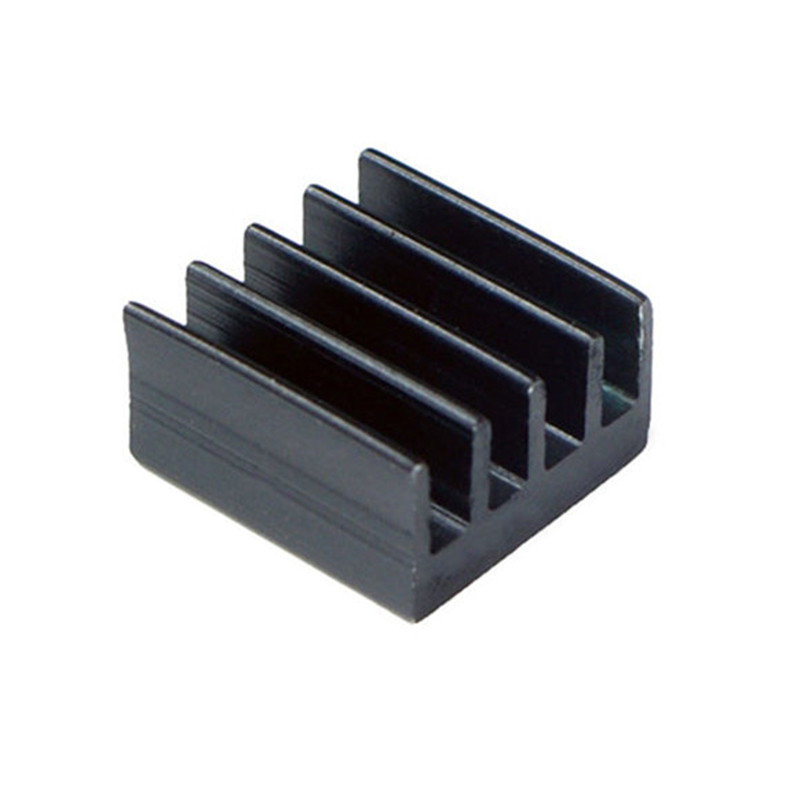

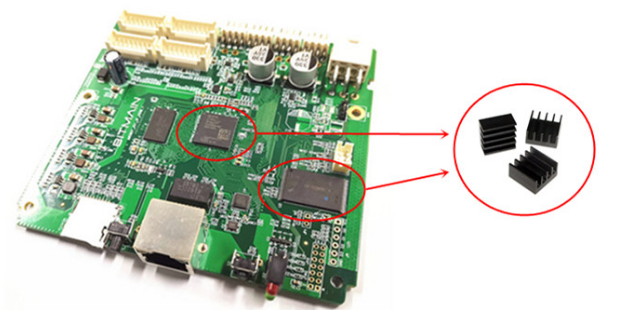

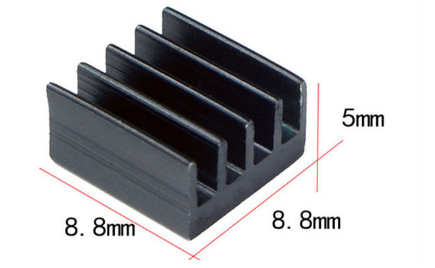

Cryptocurrency mining operations, particularly those utilizing ASIC (Application-Specific Integrated Circuit) miners, are notorious for their noise levels. The constant hum of fans working overtime to dissipate heat from high-performance mining hardware can create a cacophony that is both disruptive and inefficient. For mining operators, finding ways to reduce noise while maintaining optimal performance is a critical challenge. One often overlooked solution lies in the strategic use of heat sinks, particularly precision-engineered models like the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed for ASIC mining control boards. In this article, we’ll explore how heat sinks can contribute to noise reduction in mining operations, the technical advantages of using high-quality heat sinks, and their practical applications in real-world mining setups.

The Noise Problem in ASIC Mining Operations

ASIC miners are built for one purpose: to perform complex cryptographic calculations at incredible speeds. This intense computational activity generates significant heat, which must be dissipated to prevent overheating and hardware failure. To manage this, most ASIC miners rely on active cooling systems—typically high-speed fans—that draw in cool air and expel hot air. While effective, these fans are often the primary source of noise in mining operations.

The noise level of a mining rig can reach upwards of 75 decibels (dB), comparable to the sound of a vacuum cleaner or a busy street. In large-scale mining farms with hundreds or thousands of machines, this noise can become unbearable, posing challenges for both operators and nearby communities. Additionally, excessive noise often indicates inefficiencies in thermal management, as fans must work harder to compensate for inadequate cooling solutions.

The Role of Heat Sinks in Thermal Management

Heat sinks are passive cooling components designed to absorb and dissipate heat away from critical components, such as CPUs and power management chips on ASIC control boards. Unlike fans, which rely on moving air to cool components, heat sinks use conductive materials (typically aluminum or copper) to transfer heat from the source to a larger surface area, where it can be naturally dissipated into the surrounding environment.

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a prime example of a thermal management solution tailored for ASIC mining applications. Its compact yet highly efficient design addresses the unique challenges of cryptocurrency mining, where space is limited, and heat generation is intense. By integrating such heat sinks into mining hardware, operators can significantly reduce the thermal load on active cooling systems, thereby lowering noise levels.

How Heat Sinks Contribute to Noise Reduction

- Reducing Fan Dependency: The primary way heat sinks help reduce noise is by decreasing the workload of cooling fans. When heat sinks effectively dissipate heat, fans don’t need to operate at maximum speed, resulting in quieter operation. The multi-piece construction and thermal interface material (TIM) of the 8.8mm heat sink ensure efficient heat transfer, minimizing the need for aggressive fan activity.

- Stabilizing Operating Temperatures: Consistent thermal regulation prevents temperature spikes that trigger sudden increases in fan speed. The advanced thermal management capabilities of this heat sink maintain steady temperatures, reducing the likelihood of noisy thermal throttling events.

- Optimizing Airflow: The environmental control excellence of this heat sink improves airflow management within the mining rig. By strategically distributing heat, it reduces hotspots that demand localized cooling, allowing fans to operate more quietly and efficiently.

- Enhancing System Efficiency: By minimizing thermal-induced power losses, heat sinks contribute to overall system efficiency. This not only lowers energy consumption but also reduces the strain on cooling systems, further contributing to noise reduction.

Practical Applications in Mining Operations

For mining operators, integrating high-quality heat sinks like the 8.8mm × 8.8mm × 5mm aluminum alloy model offers several practical benefits:

- Improved Hardware Longevity: By maintaining optimal operating temperatures, heat sinks protect ASIC components from thermal degradation, extending the lifespan of expensive mining hardware.

- Lower Operating Costs: Reduced fan usage translates to lower electricity consumption, cutting operational expenses over time.

- Enhanced Mining Performance: Stable temperatures prevent thermal throttling, ensuring consistent hash rates and maximizing mining efficiency.

- Operator Comfort: Quieter mining environments improve working conditions for operators and reduce noise-related complaints in residential or commercial settings.

Key Features of the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

To understand why this heat sink is particularly effective for noise reduction in ASIC mining, let’s examine its standout features:

- Optimized Spatial Efficiency: Its compact dimensions make it ideal for tight spaces within mining rigs, ensuring it doesn’t interfere with other components.

- Advanced Thermal Management: The heat sink’s design maximizes heat dissipation, keeping critical components within safe temperature ranges.

- Durability-Focused Design: Constructed from premium aluminum alloy, it withstands prolonged exposure to high temperatures without losing effectiveness.

- Thermal Interface Optimization: The TIM layer ensures maximum heat transfer efficiency, enhancing the heat sink’s overall performance.

- Installation Versatility: Compatible with various control board configurations, it can be easily integrated into different mining setups.

Real-World Example: Noise Reduction in a Mining Farm

Consider a medium-sized mining farm with 100 ASIC miners. Each miner operates at an average noise level of 75 dB, primarily due to high-speed fans. By installing the 8.8mm × 8.8mm × 5mm heat sink on each control board, the farm operator observes a noticeable reduction in fan speeds. The noise level drops to approximately 65 dB, creating a more manageable environment for workers and reducing the risk of noise complaints from neighboring properties. Additionally, the farm experiences a 10% reduction in electricity costs due to decreased fan usage.

Conclusion

In the world of cryptocurrency mining, where efficiency and performance are paramount, addressing noise pollution is often an afterthought. However, by incorporating precision-engineered heat sinks like the 8.8mm × 8.8mm × 5mm aluminum alloy model, operators can achieve a dual benefit: improved thermal management and significant noise reduction. This solution not only enhances the comfort and sustainability of mining operations but also contributes to longer hardware lifespans and lower operating costs. For mining operators seeking to optimize their setups, investing in high-quality heat sinks is a practical and impactful step forward.