Can using heat sinks improve the environmental control of mining rigs?

August 2, 2025

Can Using Heat Sinks Improve the Environmental Control of Mining Rigs?

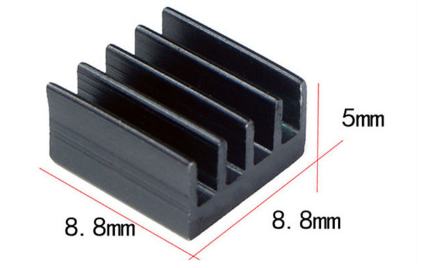

Cryptocurrency mining is an energy-intensive process that generates significant heat, creating challenges for maintaining optimal operating conditions. As mining rigs, particularly those using ASIC (Application-Specific Integrated Circuit) technology, become more powerful, managing thermal output becomes critical to ensuring performance, efficiency, and longevity. One of the most effective solutions to this challenge is the implementation of precision-engineered heat sinks. This article explores how the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink can revolutionize environmental control in mining rigs, offering practical advantages and operational benefits for cryptocurrency miners.

The Role of Heat Sinks in Cryptocurrency Mining

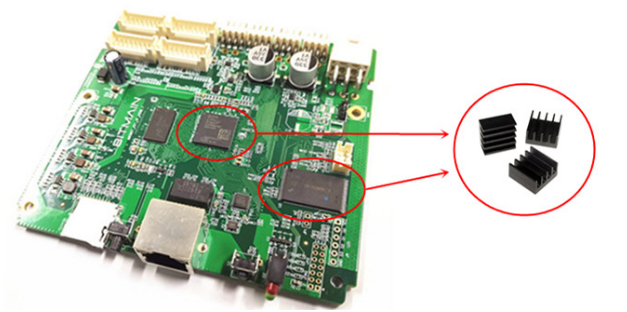

ASIC mining rigs are designed to perform complex cryptographic calculations at high speeds, a process that inherently generates substantial heat. Without proper thermal management, this heat can lead to thermal throttling, reduced computational efficiency, and even hardware failure. Heat sinks play a pivotal role in dissipating this excess heat, ensuring that critical components such as CPUs and power management chips operate within safe temperature ranges.

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is specifically engineered for ASIC mining control boards, addressing the demanding thermal requirements of cryptocurrency mining operations. Its compact design, advanced thermal architecture, and durability make it an ideal solution for improving environmental control in mining rigs.

Product Introduction: Precision-Engineered Heat Sink

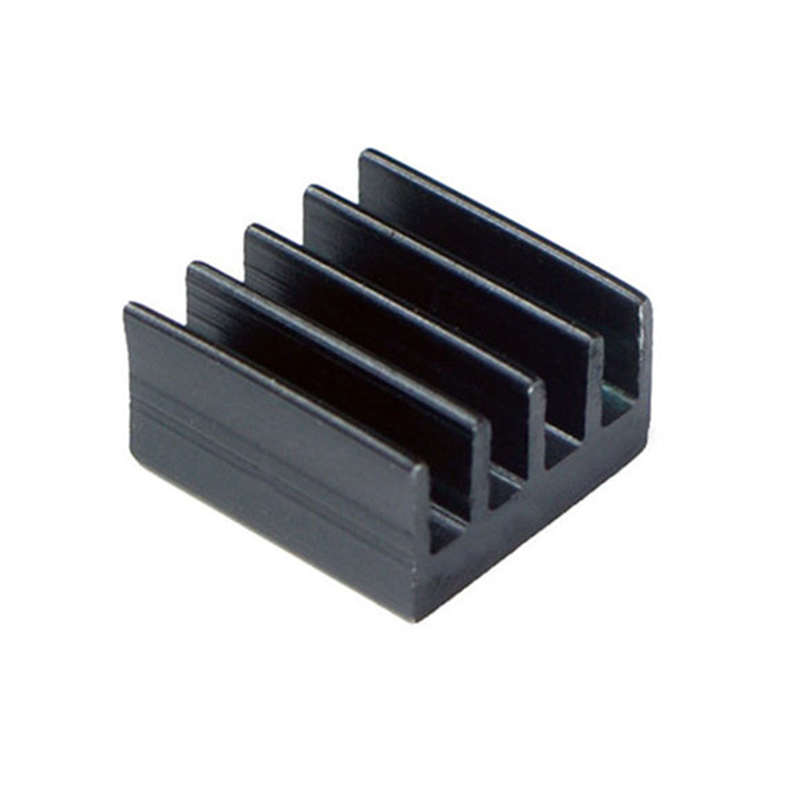

This heat sink is crafted from high-grade aluminum alloy, a material known for its excellent thermal conductivity and lightweight properties. The multi-piece construction maximizes thermal dissipation efficiency by facilitating rapid heat transfer away from critical components. Its compact form factor (8.8mm × 8.8mm × 5mm) ensures it fits seamlessly into mining rigs without occupying excessive space, a crucial consideration given the tight configurations of modern mining setups.

A key feature of this heat sink is its integration with a specialized thermal interface material (TIM). This thermally conductive silica gel layer enhances heat transfer between the heat-generating components and the heat sink surface, creating an efficient thermal pathway for heat dissipation. This ensures that heat is effectively channeled away from sensitive components, maintaining stable operating temperatures.

Product Advantages: Real-World Benefits for Miners

- Optimized Spatial Efficiency

Mining rigs often operate in confined spaces, making efficient use of available real estate essential. The 8.8mm × 8.8mm × 5mm heat sink is designed to maximize cooling performance while minimizing its spatial footprint. This balance allows miners to integrate advanced thermal management without compromising on space or airflow within the rig.

- Advanced Thermal Management

Consistent temperature control is critical for maintaining ASIC performance. This heat sink delivers superior thermal regulation, preventing thermal throttling and extending the lifespan of mining components. By keeping temperatures within safe limits, it ensures uninterrupted mining operations and reduces the risk of hardware failure.

- Enhanced Power Efficiency

Excessive heat can lead to thermal-induced power losses, reducing the overall efficiency of mining rigs. This heat sink’s efficient heat dissipation minimizes these losses, resulting in improved system efficiency and lower operating costs. Additionally, stable temperatures ensure consistent power delivery to critical components, optimizing mining performance.

- Environmental Control Excellence

Heat sinks not only manage heat but also contribute to better airflow and heat distribution within the mining rig. The multi-piece design of this heat sink facilitates improved air circulation, creating an optimized microenvironment around critical components. This strategic airflow management enhances the overall environmental control of the mining setup.

- Durability-Focused Design

Mining rigs operate continuously under high-temperature conditions, requiring components that can withstand prolonged stress. The premium aluminum alloy construction of this heat sink ensures long-term reliability and consistent thermal performance, even in the most demanding mining environments.

- Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency. This ensures that heat is evenly distributed across the contact area, preventing hot spots and maintaining consistent thermal conductivity.

- Installation Versatility

Compatibility with various control board configurations makes this heat sink a versatile solution for different mining hardware setups. Its design ensures optimal thermal contact, regardless of the specific configuration, making it a practical choice for a wide range of mining operations.

Practical Applications and Operational Insights

In real-world mining operations, the implementation of this heat sink translates to tangible benefits. For example, in a large-scale mining farm where hundreds of ASIC miners operate simultaneously, maintaining optimal temperatures is a constant challenge. The 8.8mm × 8.8mm × 5mm heat sink can be installed on control boards to effectively dissipate heat, reducing the risk of overheating and ensuring consistent performance.

Consider a scenario where a mining rig experiences frequent thermal throttling due to inadequate cooling. By integrating this heat sink, miners can achieve steady-state temperature control, eliminating performance bottlenecks and maximizing hash rates. Over time, this leads to increased profitability and reduced downtime.

Moreover, the heat sink’s enhanced power efficiency directly impacts operational costs. By minimizing thermal-induced power losses, miners can reduce their electricity consumption, a significant expense in cryptocurrency mining. This cost-saving benefit, combined with the extended lifespan of mining hardware, makes the heat sink a valuable investment for both small-scale and industrial mining operations.

Conclusion: A Game-Changer for Mining Environmental Control

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents a critical advancement in thermal management for cryptocurrency mining rigs. Its precision-engineered design, advanced thermal capabilities, and practical benefits make it an indispensable tool for miners seeking to optimize their operations. By improving environmental control, enhancing power efficiency, and ensuring hardware durability, this heat sink addresses the core challenges of modern mining, paving the way for more sustainable and profitable operations.

For cryptocurrency communities and mining operators, investing in high-quality thermal management solutions like this heat sink is not just a technical upgrade—it’s a strategic move toward achieving long-term success in the competitive world of cryptocurrency mining.