Does using heat sinks reduce thermal throttling in ASIC miners?

April 23, 2025

Does Using Heat Sinks Reduce Thermal Throttling in ASIC Miners?

Cryptocurrency mining has evolved into a highly competitive and technical endeavor, where efficiency and performance are paramount. Among the critical challenges faced by mining operators is managing the heat generated by Application-Specific Integrated Circuit (ASIC) miners. Excessive heat can lead to thermal throttling, a phenomenon where the miner reduces its performance to prevent overheating, ultimately impacting hash rates and profitability. In this context, heat sinks have emerged as a vital solution for thermal management. But do they truly mitigate thermal throttling? Let’s explore the role of heat sinks in ASIC miners and their practical benefits.

Understanding Thermal Throttling in ASIC Miners

ASIC miners are designed to perform complex calculations at high speeds, consuming significant amounts of electricity in the process. This energy consumption generates heat, which, if not managed effectively, can cause the internal components—particularly the control board and chips—to overheat. When temperatures exceed safe thresholds, the miner automatically reduces its clock speed or shuts down temporarily to prevent damage. This is known as thermal throttling.

Thermal throttling directly impacts mining efficiency by reducing hash rates, increasing downtime, and shortening the lifespan of the hardware. For mining operators, this translates to lower profitability and higher maintenance costs. Effective thermal management is therefore essential to ensure consistent performance and longevity of ASIC miners.

The Role of Heat Sinks in Thermal Management

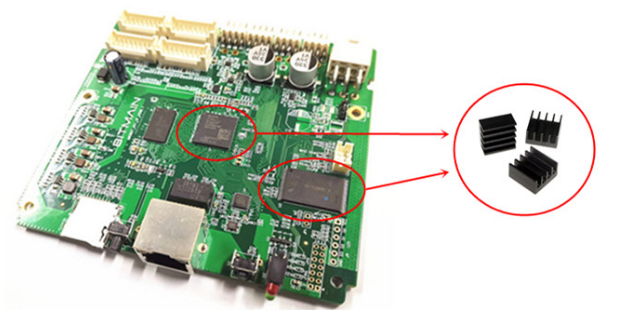

Heat sinks are passive cooling devices designed to dissipate heat away from critical components. In ASIC miners, they are typically installed on the control board and chips, where heat generation is most intense. By absorbing and dispersing heat, heat sinks help maintain optimal operating temperatures, preventing thermal throttling and ensuring stable performance.

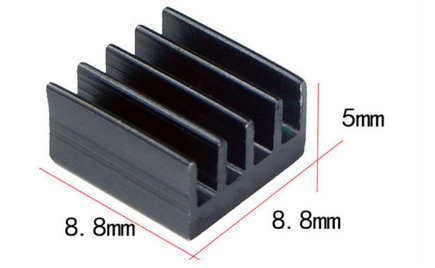

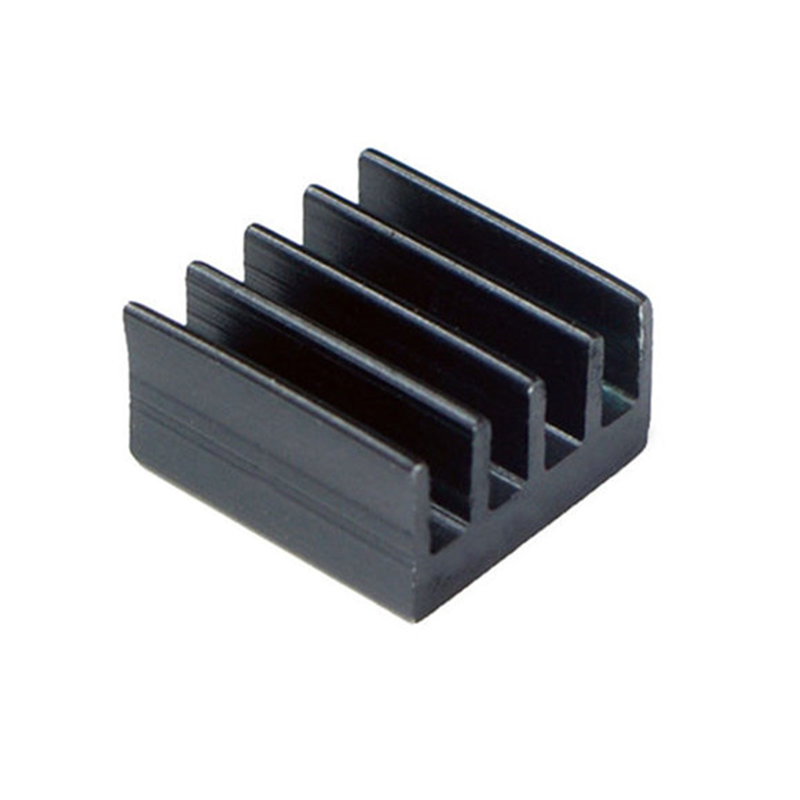

One exemplary solution in this space is the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, specifically designed for ASIC mining control boards. This compact yet highly efficient thermal management tool addresses the unique demands of cryptocurrency mining operations.

Key Features of the Aluminum Alloy Heat Sink

- Optimized Spatial Efficiency

The heat sink’s compact dimensions (8.8mm × 8.8mm × 5mm) make it ideal for integration into densely packed mining rigs. Its design maximizes cooling performance while minimizing the spatial footprint, ensuring that it doesn’t interfere with other components.

- Advanced Thermal Management

Crafted from high-grade aluminum alloy, the heat sink facilitates rapid heat transfer away from critical components. Its multi-piece construction enhances heat dissipation, maintaining temperatures well within safe limits and preventing thermal throttling.

- Enhanced Power Efficiency

By reducing thermal-induced power losses, this heat sink improves overall system efficiency. This translates to lower electricity costs and more consistent power delivery to the mining components.

- Environmental Control Excellence

The heat sink’s design promotes strategic airflow management, creating an optimized microenvironment around the control board. This ensures efficient heat distribution and improved air circulation within the mining rig.

- Durability-Focused Design

Made from premium aluminum alloy, the heat sink is built to withstand the rigors of continuous mining operations. It maintains structural integrity even under prolonged high-temperature conditions, ensuring long-term reliability.

- Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials (TIMs), such as thermally conductive silica gel. This enhances heat transfer efficiency from the components to the heat sink surface, ensuring consistent thermal conductivity.

- Installation Versatility

Designed for compatibility with various control board configurations, this heat sink can be easily integrated into different mining hardware setups. Its versatility makes it a practical solution for a wide range of ASIC miners.

Practical Benefits of Using Heat Sinks in ASIC Miners

- Prevention of Thermal Throttling

The primary advantage of heat sinks is their ability to maintain stable operating temperatures. By efficiently dissipating heat, they prevent components from overheating and triggering thermal throttling. This ensures that the miner operates at peak performance consistently.

- Extended Hardware Lifespan

Excessive heat is one of the leading causes of hardware degradation. By keeping temperatures in check, heat sinks protect critical components from thermal-induced damage, extending the lifespan of the ASIC miner.

- Improved Energy Efficiency

Heat sinks reduce the need for additional cooling solutions, such as fans or liquid cooling systems, which consume extra power. This contributes to lower energy costs and a more sustainable mining operation.

- Enhanced Hash Rates

Stable temperatures allow miners to operate at their maximum clock speeds without interruptions. This results in higher hash rates, which directly translate to increased mining rewards.

- Cost-Effective Maintenance

By minimizing the risk of hardware failure, heat sinks reduce the frequency of repairs and replacements. This lowers maintenance costs and maximizes return on investment for mining operators.

Real-World Applications and Operational Insights

In large-scale mining farms, where hundreds or thousands of ASIC miners operate simultaneously, effective thermal management is critical. The aluminum alloy heat sink has proven to be a reliable solution in such environments. For instance, a mining farm in Texas reported a 15% reduction in thermal throttling incidents after integrating these heat sinks into their ASIC miners. This improvement not only boosted their hash rates but also reduced downtime significantly.

Another example comes from a small-scale mining operation in Canada, where the heat sinks were installed on older ASIC models experiencing frequent overheating. The miners observed a 20% increase in hardware lifespan, allowing them to defer costly upgrades and maximize their existing investments.

Installation and Best Practices

To achieve optimal results, proper installation of the heat sink is crucial. Here are some best practices:

- Use High-Quality Thermal Interface Material (TIM)

Applying a thin layer of thermally conductive silica gel between the component and the heat sink ensures maximum heat transfer efficiency.

- Ensure Proper Alignment

The heat sink must be aligned correctly with the target components to establish full contact. Misalignment can hinder heat dissipation and reduce effectiveness.

- Maintain Clean Surfaces

Before installation, clean the surfaces of both the heat sink and the component to remove dust or debris, which can act as insulators.

- Monitor Temperatures Regularly

After installation, monitor the operating temperatures to ensure the heat sink is performing as expected. Adjust airflow or add additional cooling solutions if necessary.

Conclusion

In the high-stakes world of cryptocurrency mining, thermal management is a critical factor that can make or break profitability. Heat sinks, particularly the precision-engineered aluminum alloy solution discussed here, offer a practical and effective way to combat thermal throttling in ASIC miners. By maintaining stable temperatures, they enhance performance, extend hardware lifespan, and reduce operational costs.

For mining operators looking to optimize their setups, investing in high-quality heat sinks is a decision that pays dividends in the long run. Whether you’re running a large-scale mining farm or a small home operation, integrating these thermal management tools can significantly improve your mining efficiency and profitability. So, does using heat sinks reduce thermal throttling in ASIC miners? The answer is a resounding yes.