Does using heat sinks reduce thermal throttling in ASIC miners?

June 10, 2025

Does Using Heat Sinks Reduce Thermal Throttling in ASIC Miners?

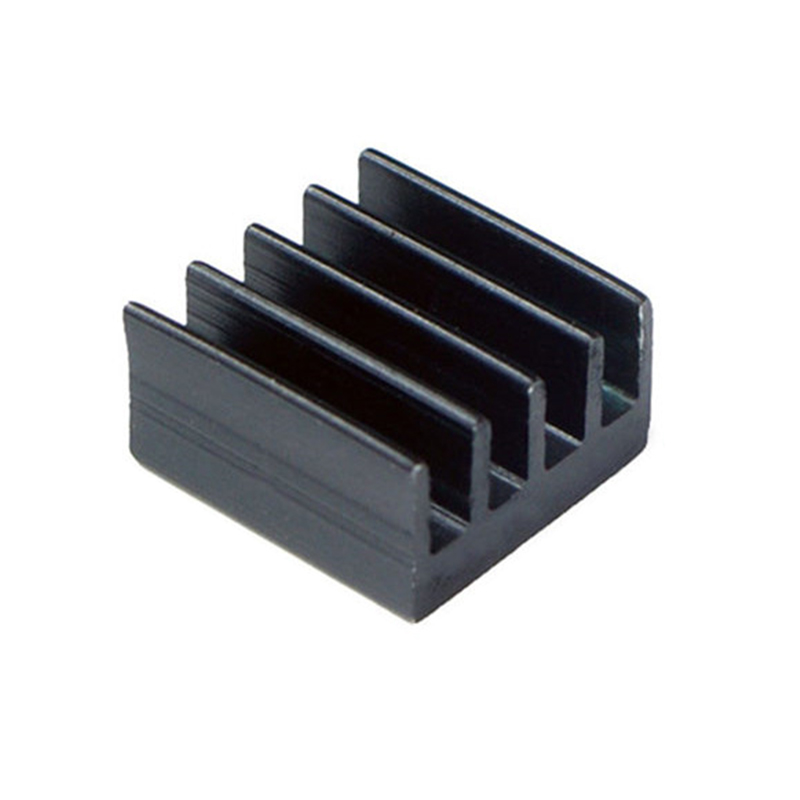

Cryptocurrency mining is a demanding process that pushes hardware to its limits, particularly ASIC (Application-Specific Integrated Circuit) miners. These devices are designed for maximum efficiency in solving cryptographic puzzles, but their high computational power generates significant heat. Without proper thermal management, this heat can lead to thermal throttling, a process where the miner reduces its performance to prevent overheating. This not only decreases mining efficiency but also shortens the lifespan of the hardware. One of the most effective solutions to combat this issue is the use of heat sinks. In this article, we’ll explore how heat sinks, specifically the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, can reduce thermal throttling and enhance the performance of ASIC miners.

The Role of Heat Sinks in ASIC Mining

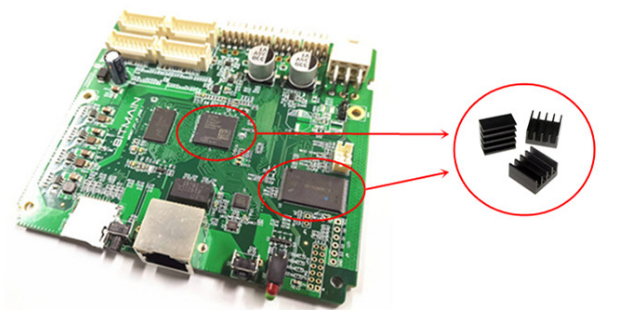

Heat sinks are passive cooling devices designed to dissipate heat away from critical components, such as CPUs and power management chips on ASIC control boards. They work by increasing the surface area available for heat transfer, allowing heat to be efficiently moved away from the source and into the surrounding environment. In the context of ASIC mining, where continuous operation at high temperatures is the norm, heat sinks play a crucial role in maintaining stable performance.

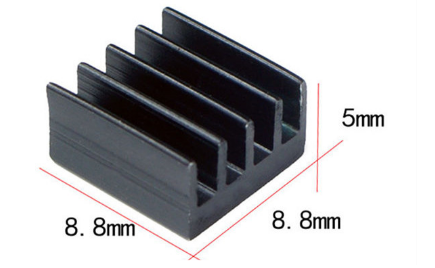

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a prime example of a thermal management solution tailored for ASIC miners. Its compact design and advanced engineering make it an ideal choice for addressing the thermal challenges faced by mining operators.

How Heat Sinks Prevent Thermal Throttling

Thermal throttling occurs when a device’s internal temperature exceeds safe operating limits, forcing it to reduce its clock speed or shut down temporarily to cool off. For ASIC miners, this means reduced hash rates and lost mining opportunities. Here’s how heat sinks help mitigate this issue:

- Efficient Heat Dissipation:

The aluminum alloy construction of the heat sink provides excellent thermal conductivity, allowing it to quickly absorb and disperse heat from the control board’s components. This prevents heat buildup and keeps temperatures within safe limits.

- Optimized Airflow Management:

The multi-piece design of the heat sink facilitates improved air circulation around critical components. By strategically directing airflow, it ensures that heat is evenly distributed and expelled from the mining rig.

- Thermal Interface Material (TIM) Integration:

The heat sink is designed to work seamlessly with thermal interface materials, such as thermally conductive silica gel. This layer enhances the contact between the heat-generating components and the heat sink, maximizing heat transfer efficiency.

- Compact and Lightweight Design:

Despite its small size (8.8mm × 8.8mm × 5mm) and lightweight (0.01 KG), the heat sink delivers exceptional thermal performance without adding unnecessary bulk to the mining rig. This makes it suitable for densely packed mining setups.

Advantages of the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

This heat sink stands out in the market due to its unique combination of features and benefits, which directly address the needs of cryptocurrency mining operations:

1. Optimized Spatial Efficiency

The compact dimensions of the heat sink ensure it fits seamlessly into mining rigs without occupying excessive space. This is particularly important in large-scale mining farms, where every millimeter of space counts.

2. Advanced Thermal Management

By maintaining consistent temperatures at critical device nodes, the heat sink helps prevent thermal throttling and extends the lifespan of ASIC components. This translates to more reliable and efficient mining operations.

3. Enhanced Power Efficiency

Efficient heat dissipation reduces thermal-induced power losses, improving the overall energy efficiency of the mining rig. This not only lowers operating costs but also contributes to a more sustainable mining operation.

4. Environmental Control Excellence

The heat sink’s design creates an optimized microenvironment around critical components, ensuring they operate within ideal temperature ranges even under heavy workloads.

5. Durability-Focused Design

Made from premium aluminum alloy, the heat sink is built to withstand the rigors of continuous mining operations. Its robust construction ensures long-term reliability and consistent performance.

6. Installation Versatility

The heat sink is compatible with a wide range of control board configurations, making it a versatile solution for different mining hardware setups.

Real-World Applications and Benefits

In practical terms, integrating the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink into ASIC mining operations offers several tangible benefits:

- Increased Hash Rates: By preventing thermal throttling, the heat sink ensures that miners operate at their maximum computational capacity, leading to higher hash rates and greater mining rewards.

- Extended Hardware Lifespan: Consistent temperature control reduces wear and tear on components, prolonging the life of expensive mining equipment.

- Reduced Downtime: With fewer instances of overheating, miners experience less downtime, resulting in more consistent and profitable operations.

- Lower Energy Costs: Improved thermal efficiency reduces the need for additional cooling solutions, such as fans or liquid cooling systems, which can consume significant amounts of power.

Installation and Maintenance Tips

To maximize the effectiveness of the heat sink, follow these best practices:

- Proper Alignment: Ensure the heat sink is correctly aligned with the heat-generating components on the control board to achieve optimal thermal contact.

- Use High-Quality TIM: Apply a thin, even layer of thermal interface material to enhance heat transfer between the components and the heat sink.

- Regular Cleaning: Dust and debris can accumulate on the heat sink over time, reducing its efficiency. Regularly clean the heat sink to maintain peak performance.

- Monitor Temperatures: Use monitoring tools to track the temperature of your mining rig and ensure the heat sink is functioning as intended.

Conclusion

In the high-stakes world of cryptocurrency mining, every degree of temperature matters. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a game-changing solution for managing the thermal challenges of ASIC miners. By efficiently dissipating heat, preventing thermal throttling, and enhancing overall performance, this heat sink empowers mining operators to achieve greater efficiency, reliability, and profitability. Whether you’re running a small-scale operation or a large mining farm, investing in high-quality thermal management solutions like this heat sink is a smart move that pays dividends in the long run.