How do heat sinks improve ASIC miner cooling under high-load conditions?

April 14, 2025

How Do Heat Sinks Improve ASIC Miner Cooling Under High-Load Conditions?

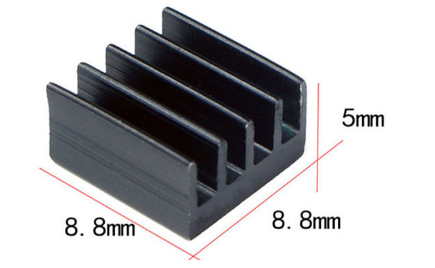

Cryptocurrency mining is an energy-intensive process that generates significant heat, particularly in Application-Specific Integrated Circuit (ASIC) miners. As mining operations scale and equipment runs at maximum capacity, effective thermal management becomes critical to maintaining performance and extending hardware lifespan. One of the most essential components in this regard is the heat sink, a precision-engineered solution designed to dissipate heat efficiently. In this article, we’ll explore how advanced heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy model, improve ASIC miner cooling under high-load conditions and why they are indispensable for modern mining operations.

The Role of Heat Sinks in ASIC Miner Cooling

Why Thermal Management Matters

ASIC miners are designed to perform complex cryptographic calculations at high speeds, consuming substantial amounts of electricity in the process. This energy consumption generates heat, which, if not managed properly, can lead to several issues:

- Thermal Throttling: To prevent overheating, ASIC miners may reduce their operating speed, directly impacting hash rates and profitability.

- Component Degradation: Prolonged exposure to high temperatures can damage sensitive components, such as CPUs and power management chips, reducing the lifespan of the hardware.

- Increased Energy Costs: Inefficient cooling systems force miners to rely more on external cooling solutions, driving up operational expenses.

Heat sinks address these challenges by providing a passive yet highly effective method of dissipating heat away from critical components. By maintaining optimal temperatures, heat sinks ensure that ASIC miners operate at peak efficiency, even under high-load conditions.

Introducing the Precision-Engineered Aluminum Alloy Heat Sink

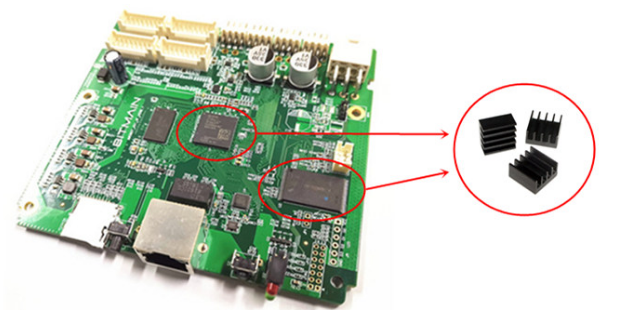

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution specifically designed for ASIC mining control boards. Its compact design and advanced engineering make it an ideal choice for modern mining rigs, where space is at a premium and cooling efficiency is paramount.

Technical Architecture

Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction optimized for maximum thermal dissipation. The material’s excellent thermal conductivity ensures rapid heat transfer from critical components, such as CPUs and power management chips, to the heat sink’s surface. From there, the heat is dispersed into the surrounding air, preventing it from accumulating within the mining rig.

The heat sink’s design incorporates advanced thermal engineering principles, including strategically placed fins that increase the surface area available for heat dissipation. These fins facilitate improved airflow, allowing heat to escape more efficiently.

Thermal Interface Integration

To further enhance thermal transfer efficiency, this heat sink is designed to work seamlessly with thermal interface materials (TIMs), such as thermally conductive silica gel. The TIM creates a bridge between the heat-generating components and the heat sink, ensuring optimal thermal conductivity. This integration minimizes thermal resistance, enabling faster and more efficient heat dissipation.

The Advantages of Advanced Heat Sinks in Mining Operations

1. Optimized Spatial Efficiency

One of the standout features of this heat sink is its compact form factor (8.8mm × 8.8mm × 5mm), which maximizes cooling performance while minimizing spatial footprint. In densely packed mining rigs, every millimeter of space counts. This heat sink’s precise dimensions ensure it fits seamlessly into existing setups without compromising on thermal management capabilities.

2. Advanced Thermal Management

Under high-load conditions, ASIC miners generate significant heat, which can push components beyond their thermal limits. The aluminum alloy heat sink excels at maintaining steady-state temperature control, preventing thermal throttling and ensuring consistent performance. By keeping critical components within their optimal temperature range, this heat sink helps extend the lifespan of mining hardware.

3. Enhanced Power Efficiency

Inefficient cooling systems can lead to thermal-induced power losses, reducing the overall efficiency of mining operations. This heat sink’s advanced design minimizes such losses by dissipating heat quickly and effectively. As a result, miners can achieve better power efficiency, translating to lower operating costs and higher profitability.

4. Environmental Control Excellence

The multi-piece construction of this heat sink facilitates strategic airflow management, creating an optimized microenvironment around critical components. By improving air circulation and heat displacement, it helps maintain a stable operating environment, even in high-temperature mining facilities.

5. Durability-Focused Design

Mining operations often run 24/7, subjecting hardware to continuous high-temperature conditions. The premium aluminum alloy construction of this heat sink ensures long-term reliability and consistent thermal performance. Its robust design maintains structural integrity, even under the most demanding conditions.

6. Installation Versatility

This heat sink is designed for compatibility with various control board configurations, making it a versatile solution for different mining hardware setups. Whether you’re using older ASIC models or the latest generation of miners, this heat sink can be easily integrated into your system without compromising thermal contact.

Real-World Applications and Operational Benefits

Preventing Thermal Throttling

In a high-load mining scenario, an ASIC miner without adequate cooling may experience thermal throttling, reducing its hash rate and profitability. By implementing this heat sink, miners can maintain consistent temperatures, ensuring that their hardware operates at full capacity without interruptions.

Extending Hardware Lifespan

Heat is one of the primary factors contributing to hardware degradation. By effectively dissipating heat, this heat sink helps protect sensitive components, such as CPUs and power management chips, from thermal-induced damage. This not only reduces maintenance costs but also extends the overall lifespan of the mining equipment.

Reducing Operational Costs

Efficient cooling systems reduce the need for additional cooling solutions, such as external fans or air conditioning. By lowering the reliance on these energy-intensive solutions, miners can significantly reduce their operational expenses, improving their bottom line.

Enhancing Mining Efficiency

With consistent temperature control, ASIC miners can operate at peak efficiency, maximizing hash rates and profitability. This is particularly important for large-scale mining operations, where even small improvements in efficiency can translate to substantial gains.

Conclusion

In the competitive world of cryptocurrency mining, every advantage counts. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents a critical investment in thermal management, offering a compact, efficient, and durable solution for ASIC miner cooling. By addressing the challenges of high-load conditions, this heat sink helps miners maintain optimal performance, extend hardware lifespan, and reduce operational costs.

Whether you’re running a small-scale mining operation or managing a large facility, integrating advanced heat sinks into your setup is a practical and cost-effective way to enhance your mining efficiency. As the industry continues to evolve, investing in reliable thermal management solutions like this heat sink will remain essential for staying ahead of the curve.