How does a heat sink improve air circulation and cooling in mining rigs?

July 30, 2025

How Does a Heat Sink Improve Air Circulation and Cooling in Mining Rigs?

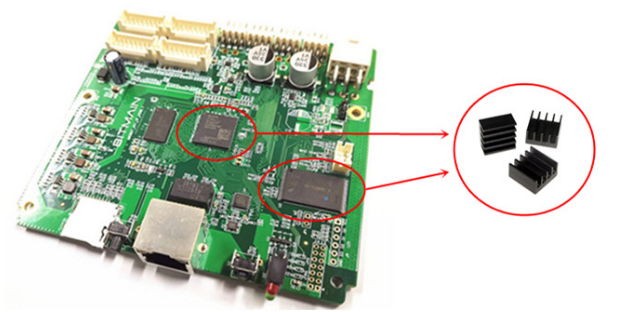

Cryptocurrency mining is an energy-intensive process that generates significant heat, particularly in ASIC (Application-Specific Integrated Circuit) miners. Efficient thermal management is crucial to maintaining optimal performance and extending the lifespan of mining hardware. Among the most critical components in this system is the heat sink, a precision-engineered solution designed to dissipate heat and improve air circulation within mining rigs. In this article, we’ll explore how heat sinks, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, play a pivotal role in enhancing cooling efficiency and ensuring the reliability of mining operations.

The Role of Heat Sinks in Cryptocurrency Mining

ASIC miners are designed for high-performance computing, but their intensive workloads produce substantial heat. Without proper cooling, this heat can lead to thermal throttling, reduced efficiency, and even permanent damage to sensitive components like control boards and chips. This is where heat sinks come into play.

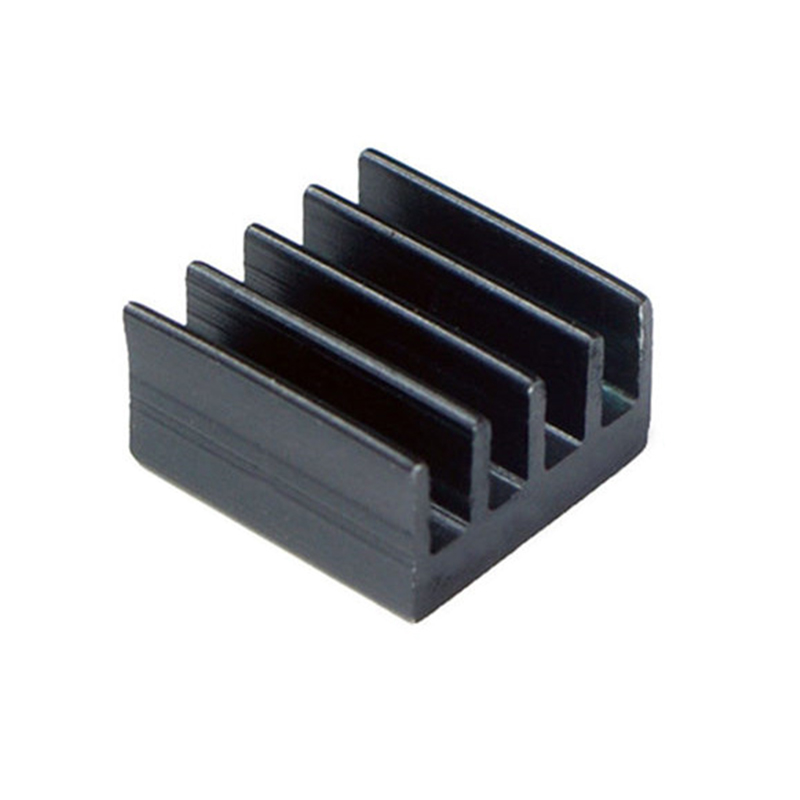

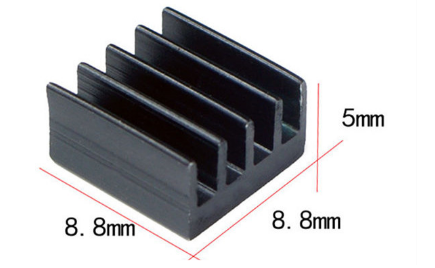

A heat sink is a passive cooling device that absorbs and dissipates heat from high-temperature components, transferring it to the surrounding air. By doing so, it prevents overheating and maintains stable operating temperatures, which are essential for consistent mining performance. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is specifically engineered for ASIC miner control boards, offering a compact yet highly efficient solution for thermal management.

Product Introduction: The Aluminum Alloy Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a state-of-the-art cooling component designed to meet the rigorous demands of cryptocurrency mining. Its compact size and lightweight construction make it ideal for integration into densely packed mining rigs, where space is often at a premium.

Technical Architecture

Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction optimized for maximum thermal dissipation. Its design incorporates advanced engineering principles to facilitate rapid heat transfer from critical components, such as CPUs and power management chips on mining control boards.

Thermal Interface Integration

The heat sink’s efficiency is further enhanced by a specialized thermal interface material (TIM) layer. This thermally conductive silica gel ensures optimal contact between the heat-generating components and the heat sink surface, creating an efficient pathway for heat dissipation.

Performance Characteristics

Despite its small footprint, this heat sink delivers exceptional thermal performance. Its dimensions (8.8mm × 8.8mm × 5mm) and weight (0.01 KG) have been precisely calculated to provide effective cooling without adding unnecessary bulk to the control board assembly.

Advantages of the Aluminum Alloy Heat Sink

1. Optimized Spatial Efficiency

One of the standout features of this heat sink is its ability to maximize cooling performance while minimizing spatial footprint. In mining rigs, where every millimeter of space counts, this design ensures efficient use of available space without compromising on thermal management capabilities.

2. Advanced Thermal Management

The heat sink delivers superior temperature control at critical device nodes, maintaining optimal operating conditions within specified thermal limits. This precision helps prevent thermal throttling, ensuring consistent mining performance and extending the lifespan of ASIC hardware.

3. Enhanced Power Efficiency

By efficiently dissipating heat, the heat sink reduces thermal-induced power losses. This results in improved overall system efficiency and lower operating costs, making it an economical choice for large-scale mining operations.

4. Environmental Control Excellence

The multi-piece design of the heat sink facilitates improved air circulation and heat displacement. This creates an optimized microenvironment around critical components, reducing the risk of localized overheating and ensuring uniform cooling across the control board.

5. Durability-Focused Design

Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous mining operations. Its robust design maintains structural integrity even under prolonged high-temperature conditions, ensuring long-term reliability.

6. Thermal Interface Optimization

Engineered to work seamlessly with thermal interface materials, the heat sink maximizes heat transfer efficiency from components to its surface. This optimization ensures consistent thermal conductivity across the entire contact area, enhancing overall cooling performance.

7. Installation Versatility

The heat sink is designed for compatibility with various control board configurations, making it a versatile solution for different mining hardware setups. Its design ensures optimal thermal contact regardless of the specific layout of the control board.

Practical Applications in Mining Operations

In real-world mining operations, the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink proves invaluable. Consider a scenario where a mining farm operates hundreds of ASIC miners. Without effective cooling solutions, the cumulative heat generated could lead to frequent hardware failures and downtime.

By integrating this heat sink into the control boards, operators can achieve:

- Consistent Temperatures: The heat sink maintains stable operating temperatures, preventing thermal throttling and ensuring uninterrupted mining.

- Extended Hardware Lifespan: By reducing thermal stress on components, the heat sink helps prolong the life of expensive mining equipment.

- Improved Airflow: The multi-piece design enhances airflow within the mining rig, promoting better overall cooling efficiency.

- Cost Savings: Reduced power losses and fewer hardware replacements translate to significant cost savings over time.

Installation Tips for Maximum Efficiency

To get the most out of the aluminum alloy heat sink, follow these best practices during installation:

- Clean the Surface: Ensure the surface of the control board chip is clean and free of dust or debris before applying the heat sink.

- Apply Thermal Interface Material (TIM): Use a high-quality TIM to create an optimal thermal bond between the chip and the heat sink.

- Secure the Heat Sink: Ensure the heat sink is firmly attached to the chip to maximize contact and heat transfer.

- Monitor Airflow: Position the heat sink to align with the rig’s airflow pattern, enhancing its cooling effectiveness.

Conclusion

In the demanding world of cryptocurrency mining, effective thermal management is not just an option—it’s a necessity. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink stands out as a critical component for maintaining optimal temperatures, improving air circulation, and ensuring the longevity of mining hardware. Its compact design, advanced thermal management capabilities, and durability make it an indispensable tool for mining operators looking to maximize efficiency and minimize costs.

By integrating this heat sink into your mining rigs, you can achieve consistent performance, protect your investment, and stay ahead in the competitive cryptocurrency mining industry.