How does an aluminum alloy heat sink impact ASIC mining power consumption?

March 22, 2025

How Does an Aluminum Alloy Heat Sink Impact ASIC Mining Power Consumption?

Cryptocurrency mining has evolved into a highly competitive and technically demanding industry, where every watt of power and degree of temperature can significantly impact profitability. At the heart of this operation lies the ASIC (Application-Specific Integrated Circuit) miner, a specialized device designed to perform the complex calculations required for mining cryptocurrencies. However, as ASIC miners work tirelessly to solve these algorithms, they generate substantial heat, which, if not managed properly, can lead to reduced efficiency, increased power consumption, and even hardware failure. This is where the aluminum alloy heat sink comes into play—a critical component in the thermal management ecosystem of ASIC mining operations.

In this article, we’ll explore the role of aluminum alloy heat sinks in ASIC mining, focusing on their design, functionality, and the tangible benefits they bring to mining operations. We’ll also delve into how these heat sinks directly impact power consumption, ensuring miners can optimize their setups for maximum efficiency and longevity.

The Role of Heat Sinks in ASIC Mining

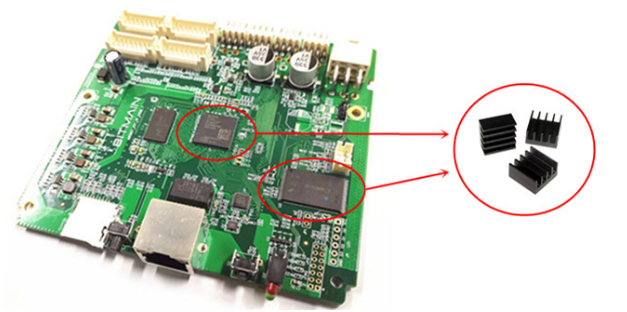

ASIC miners are engineered to operate at peak performance, but this comes at a cost: heat generation. The control board, which houses critical components such as CPUs and power management chips, is particularly susceptible to overheating. Without effective thermal management, these components can experience thermal throttling—a process where the system reduces performance to prevent damage—resulting in slower hash rates and reduced mining efficiency.

Heat sinks are essential for dissipating this excess heat. Acting as a passive cooling solution, they absorb heat from the components and transfer it to the surrounding air, maintaining optimal operating temperatures. For ASIC miners, this means consistent performance, reduced wear and tear, and lower power consumption.

Introducing the Precision-Engineered Aluminum Alloy Heat Sink

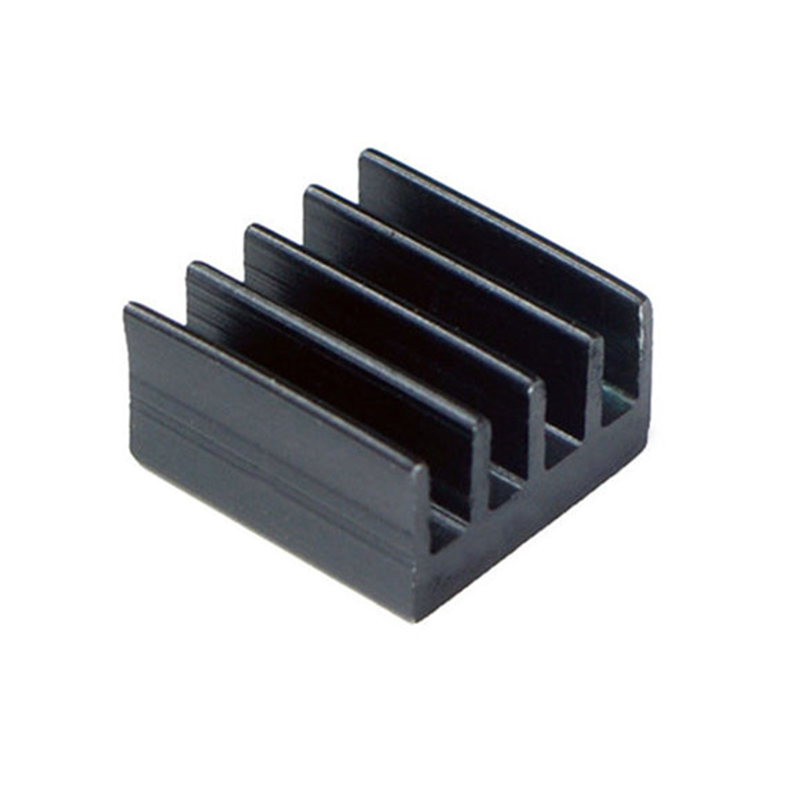

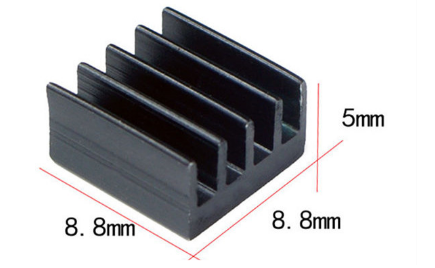

The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a game-changer for ASIC mining operations. Designed specifically for control board applications, this heat sink addresses the unique thermal challenges faced by cryptocurrency miners. Its compact form factor and lightweight design (just 0.01 KG) make it an ideal solution for modern mining rigs, where space and weight are critical considerations.

Technical Architecture

Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction optimized for maximum thermal dissipation. The material’s excellent thermal conductivity ensures rapid heat transfer away from critical components, while the design incorporates advanced engineering principles to enhance airflow and heat distribution.

Thermal Interface Integration

To further boost efficiency, the heat sink is paired with a specialized thermal interface material (TIM) layer. This thermally conductive silica gel ensures optimal contact between the heat-generating components and the heat sink, creating an efficient pathway for heat transfer. This integration is crucial for maintaining consistent temperatures and preventing hotspots that could degrade performance.

Key Advantages of Aluminum Alloy Heat Sinks in ASIC Mining

1. Optimized Spatial Efficiency

One of the standout features of this heat sink is its compact design. Measuring just 8.8mm × 8.8mm × 5mm, it fits seamlessly into densely packed mining rigs without compromising on cooling performance. This spatial efficiency is particularly valuable in large-scale mining operations, where every millimeter of space counts.

2. Advanced Thermal Management

The heat sink’s design ensures superior temperature control at critical device nodes. By maintaining operating temperatures well within specified limits, it prevents thermal throttling and ensures consistent hash rates. This precise thermal regulation is essential for maximizing mining output and protecting expensive ASIC hardware.

3. Enhanced Power Efficiency

Heat is a major contributor to power losses in electronic systems. When components overheat, they require more energy to function, driving up electricity costs. By efficiently dissipating heat, this aluminum alloy heat sink reduces thermal-induced power losses, translating to lower operating expenses and improved profitability.

4. Environmental Control Excellence

The heat sink’s multi-piece design facilitates strategic airflow management, creating an optimized microenvironment around critical components. This not only enhances heat dissipation but also improves overall system stability, especially in high-temperature environments.

5. Durability-Focused Design

Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous mining operations. Its robust design ensures long-term reliability, maintaining consistent thermal performance even under extreme conditions.

How Heat Sinks Impact ASIC Mining Power Consumption

The relationship between heat management and power consumption is a critical consideration for miners. Here’s how the aluminum alloy heat sink contributes to energy efficiency:

Preventing Thermal Throttling

When ASIC components overheat, they automatically reduce their performance to prevent damage—a process known as thermal throttling. This results in slower hash rates and increased power consumption, as the system works harder to achieve the same output. By maintaining optimal temperatures, the heat sink prevents thermal throttling, ensuring consistent performance and minimizing energy waste.

Reducing Resistance in Electrical Components

Heat increases the electrical resistance of components, leading to higher power consumption. Efficient heat dissipation keeps resistance levels low, allowing the system to operate more efficiently. This is particularly important for power management chips, which play a crucial role in regulating energy usage.

Extending Hardware Lifespan

Overheating accelerates the degradation of electronic components, leading to premature failure. By protecting critical components, the heat sink extends the lifespan of the ASIC miner, reducing the need for costly replacements and downtime. This long-term reliability translates to sustained energy efficiency and lower operational costs.

Practical Applications in Mining Operations

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is versatile and compatible with a wide range of ASIC mining configurations. Whether you’re running a small-scale home mining setup or a large-scale industrial operation, this heat sink can be seamlessly integrated into your rig. Its installation versatility ensures optimal thermal contact across different control board designs, making it a reliable solution for diverse mining hardware.

Conclusion

In the competitive world of cryptocurrency mining, every detail matters. The precision-engineered aluminum alloy heat sink represents a critical investment in thermal management, offering tangible benefits in terms of power efficiency, performance, and hardware longevity. By maintaining optimal operating temperatures, this heat sink helps miners maximize their output while minimizing energy consumption—a key factor in achieving profitability.

For mining operators looking to optimize their setups, the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a proven solution that delivers exceptional value. Its compact design, advanced thermal management capabilities, and durability-focused construction make it an indispensable component in modern ASIC mining operations. By integrating this heat sink into your rig, you can ensure consistent performance, reduce operating costs, and protect your investment in cryptocurrency mining hardware.