How does the aluminum alloy heat sink impact ASIC miner efficiency?

June 10, 2025

How Does the Aluminum Alloy Heat Sink Impact ASIC Miner Efficiency?

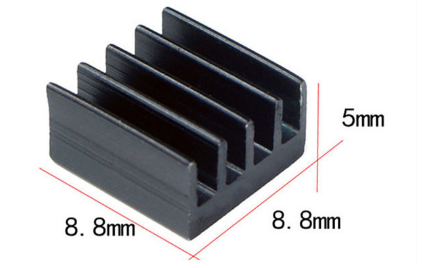

Cryptocurrency mining has evolved into a highly competitive and technically demanding industry, where even minor improvements in hardware efficiency can translate into significant operational advantages. Among the critical components that determine the performance and longevity of ASIC miners, the heat sink plays a pivotal role. Specifically, the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink has emerged as a game-changer in thermal management for ASIC mining control boards. This article explores how this advanced cooling solution impacts miner efficiency, offering practical insights for mining operators and cryptocurrency enthusiasts.

The Role of Heat Sinks in ASIC Mining

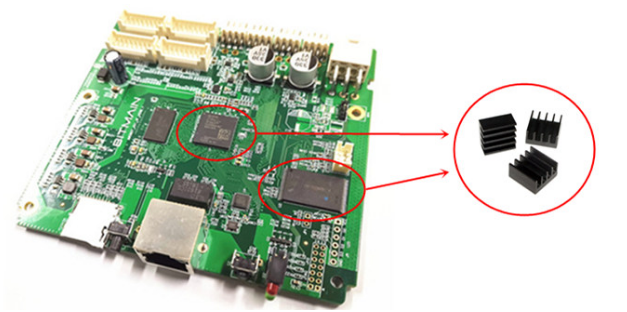

ASIC (Application-Specific Integrated Circuit) miners are designed to perform complex cryptographic calculations at high speeds, generating substantial heat in the process. Without effective thermal management, this heat can lead to thermal throttling, reduced computational efficiency, and even permanent damage to sensitive components like CPUs and power management chips. Heat sinks are essential for dissipating this heat, ensuring that miners operate within safe temperature ranges while maintaining peak performance.

Traditional heat sinks often struggle to meet the demands of modern ASIC miners, which require compact, lightweight, and highly efficient cooling solutions. This is where the aluminum alloy heat sink stands out, offering a combination of advanced engineering and practical benefits tailored to the unique challenges of cryptocurrency mining.

Product Introduction: The Aluminum Alloy Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a precision-engineered thermal management solution specifically designed for ASIC mining control boards. Its compact dimensions and lightweight construction (just 0.01 KG) make it an ideal choice for modern mining rigs, where space optimization is crucial.

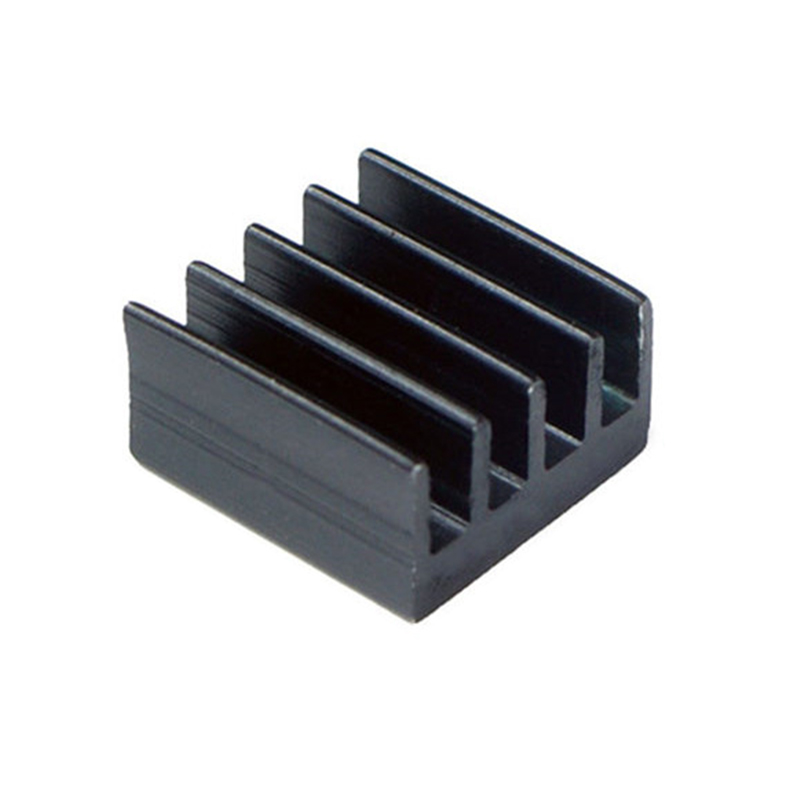

#### Technical Architecture Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction that maximizes thermal dissipation efficiency. The design incorporates advanced thermal engineering principles to facilitate rapid heat transfer from critical components, ensuring that heat is effectively displaced from the control board.

#### Thermal Interface Integration A key feature of this heat sink is its integration with specialized thermal interface materials (TIM), such as thermally conductive silica gel. This layer ensures optimal thermal conductivity between the heat-generating components and the heat sink surface, creating an efficient pathway for heat dissipation. By minimizing thermal resistance, the TIM enhances the overall cooling performance of the heat sink.

#### Performance Characteristics The heat sink’s compact form factor has been precisely calculated to provide optimal thermal management without occupying excessive space. Despite its small size, it delivers exceptional thermal performance, making it a reliable solution for maintaining steady-state temperatures in ASIC miners.

Product Advantages: Why This Heat Sink Stands Out

The aluminum alloy heat sink offers several distinct advantages that directly impact ASIC miner efficiency:

#### 1. Optimized Spatial Efficiency In mining rigs, every millimeter of space counts. The 8.8mm × 8.8mm × 5mm dimensions of this heat sink ensure that it fits seamlessly into tight spaces without compromising on cooling performance. This spatial efficiency allows miners to maximize their hardware density, potentially increasing their hash rate per unit of space.

#### 2. Advanced Thermal Management One of the most critical aspects of ASIC mining is maintaining consistent operating temperatures. This heat sink excels in delivering superior temperature control at critical device nodes, preventing thermal throttling and ensuring that miners operate at peak efficiency. By keeping components within their specified thermal limits, it also extends their lifespan, reducing the need for frequent replacements.

#### 3. Enhanced Power Efficiency Heat is a byproduct of energy consumption, and inefficient thermal management can lead to increased power losses. The aluminum alloy heat sink significantly reduces these losses by efficiently dissipating heat, resulting in improved overall system efficiency. This translates to lower electricity costs, a major consideration for mining operators.

#### 4. Environmental Control Excellence The multi-piece design of this heat sink facilitates strategic airflow management and efficient heat distribution. By creating an optimized microenvironment around critical components, it ensures that heat is evenly displaced, preventing hotspots and maintaining stable operating conditions.

#### 5. Durability-Focused Design Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous mining operations. Its robust design maintains structural integrity even under high-temperature conditions, ensuring long-term reliability and consistent performance.

#### 6. Thermal Interface Optimization The heat sink is engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency. This optimization ensures that heat is conducted away from components as quickly as possible, maintaining consistent thermal conductivity across the entire contact area.

#### 7. Installation Versatility Compatible with various control board configurations, this heat sink offers flexibility for different mining hardware setups. Its design ensures optimal thermal contact regardless of the specific layout, making it a versatile solution for a wide range of ASIC miners.

Real-World Applications and Operational Benefits

For mining operators, the practical benefits of the aluminum alloy heat sink are clear. Consider a scenario where a mining farm operates hundreds of ASIC miners 24/7. Without effective thermal management, these miners would experience frequent overheating, leading to reduced hash rates, increased downtime, and higher maintenance costs. By implementing this heat sink, operators can achieve:

- Consistent Performance: Miners operate at optimal temperatures, maintaining high hash rates without thermal throttling.

- Reduced Downtime: Fewer instances of overheating mean less downtime for repairs or cooling interventions.

- Lower Operating Costs: Improved power efficiency reduces electricity consumption, while extended component lifespan minimizes replacement expenses.

- Scalability: The compact design allows for higher hardware density, enabling operators to scale their operations without expanding physical space.

Conclusion: A Critical Component for Modern Mining

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is more than just a cooling component—it’s a strategic investment in the efficiency and longevity of ASIC mining operations. By addressing the critical challenge of thermal management, it enables miners to operate at peak performance while reducing operational costs and downtime. For mining operators looking to optimize their hardware and stay competitive in the ever-evolving cryptocurrency landscape, this heat sink represents a practical and impactful solution.

Whether you’re running a small-scale mining operation or managing a large-scale farm, integrating this advanced thermal management solution can make a significant difference in your bottom line. As the industry continues to push the boundaries of hardware performance, innovations like the aluminum alloy heat sink will remain essential for achieving sustainable and efficient mining operations.