How does the heat sink reduce thermal-induced power losses in mining rigs?

May 30, 2025

How Does the Heat Sink Reduce Thermal-Induced Power Losses in Mining Rigs?

Cryptocurrency mining has evolved into a highly competitive industry where efficiency and reliability are paramount. As mining operations scale up, the heat generated by ASIC (Application-Specific Integrated Circuit) miners becomes a significant challenge. Excessive heat not only reduces the lifespan of mining hardware but also leads to thermal-induced power losses, which can erode profitability. In this context, the role of precision-engineered heat sinks in managing thermal performance cannot be overstated. This article delves into how the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink addresses these challenges, offering a practical solution for mining operators seeking to optimize their rigs.

The Challenge of Heat in Cryptocurrency Mining

Cryptocurrency mining rigs, particularly those using ASIC chips, operate at high computational loads for extended periods. This generates substantial heat, which, if not managed effectively, can lead to several issues:

- Thermal Throttling: When components overheat, they reduce their performance to lower temperatures, resulting in decreased hash rates and mining efficiency.

- Increased Power Consumption: Excess heat forces cooling systems to work harder, consuming more electricity and driving up operational costs.

- Hardware Degradation: Prolonged exposure to high temperatures can damage critical components, shortening the lifespan of expensive mining equipment.

Given these challenges, effective thermal management is essential to maintaining optimal mining operations. This is where the ASIC miner control board/chip’s heat sink comes into play.

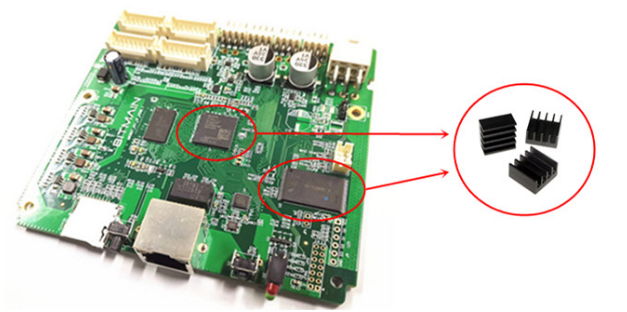

Introducing the Precision-Engineered Heat Sink

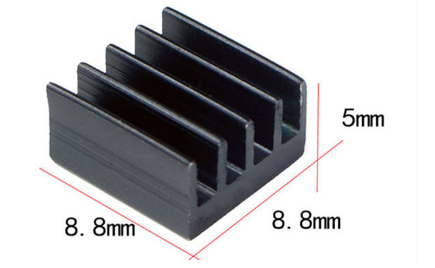

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a thermal management solution specifically designed for ASIC mining control boards. Its compact yet efficient design addresses the unique demands of cryptocurrency mining environments, where consistent temperature control is critical for both performance and hardware longevity.

Technical Architecture

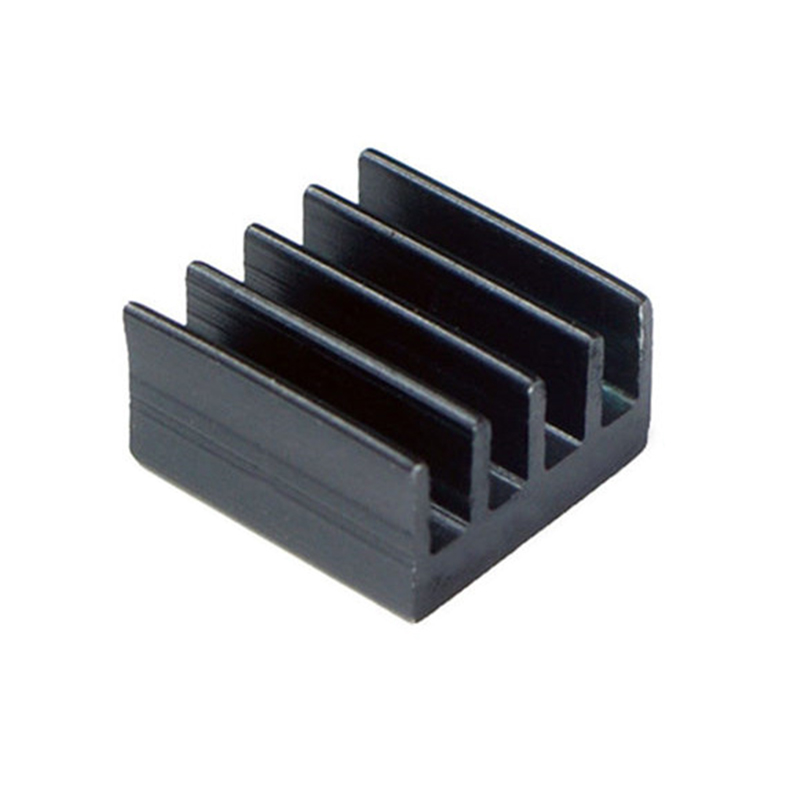

Crafted from high-grade aluminum alloy, this heat sink features an optimized multi-piece construction that maximizes thermal dissipation efficiency. Its design incorporates advanced thermal engineering principles to facilitate rapid heat transfer from critical components, such as CPUs and power management chips on mining control boards.

The lightweight construction (just 0.01 KG) ensures that it doesn’t add significant mass to the control board assembly while still delivering exceptional thermal performance.

Thermal Interface Integration

A key feature of this heat sink is its compatibility with specialized thermal interface materials (TIMs). The inclusion of a thermally conductive silica gel layer enhances heat transfer efficiency between the heat-generating components and the heat sink surface. This creates an efficient thermal pathway, ensuring that heat is dissipated quickly and effectively.

How the Heat Sink Reduces Thermal-Induced Power Losses

The relationship between heat and power efficiency in mining rigs is well-documented. Excessive heat increases electrical resistance in components, leading to higher power consumption. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink plays a crucial role in mitigating these losses through several mechanisms:

1. Enhanced Heat Dissipation

The heat sink’s multi-piece design and aluminum alloy construction enable rapid heat transfer away from critical components. By maintaining lower operating temperatures, it reduces the risk of thermal throttling and ensures that mining rigs operate at peak efficiency. This directly translates to improved hash rates and reduced power losses.

2. Optimized Airflow Management

The heat sink’s compact form factor is engineered to fit seamlessly within mining rigs, promoting better airflow around components. Efficient airflow ensures that heat is evenly distributed and expelled from the system, preventing localized hotspots that can lead to power inefficiencies.

3. Consistent Temperature Control

By maintaining steady-state temperatures, the heat sink minimizes fluctuations that can cause increased power consumption. This stability is particularly important for power management chips, which are highly sensitive to temperature variations.

4. Reduced Cooling System Load

When heat sinks effectively dissipate heat, active cooling systems (such as fans) don’t need to work as hard. This reduces the overall power consumption of the mining rig, contributing to lower operational costs.

Advantages of the Heat Sink for Mining Operators

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink offers several advantages that make it an indispensable component for cryptocurrency mining operations:

1. Optimized Spatial Efficiency

Its compact design maximizes cooling performance while minimizing spatial footprint, making it ideal for densely packed mining rigs. This ensures that operators can maximize their hardware density without compromising on thermal management.

2. Advanced Thermal Management

The heat sink delivers superior temperature control at critical device nodes, preventing thermal throttling and extending the lifespan of components. This reliability is essential for maintaining uninterrupted mining operations.

3. Enhanced Power Efficiency

By reducing thermal-induced power losses, the heat sink improves overall system efficiency. This translates to lower electricity bills and higher profitability for mining operators.

4. Durability-Focused Design

Constructed from premium aluminum alloy, the heat sink is built to withstand the rigors of continuous mining operations. Its robust design ensures consistent thermal performance even under high-temperature conditions.

5. Installation Versatility

The heat sink is compatible with various control board configurations, making it a versatile solution for different mining hardware setups. Its easy installation process ensures that operators can quickly upgrade their existing systems.

Real-World Applications and Operational Insights

In practice, the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink has proven to be a game-changer for mining operators. For example, in large-scale mining farms where hundreds of ASIC miners operate simultaneously, effective thermal management is critical. By incorporating these heat sinks, operators have reported:

- Improved Hash Rates: Consistent temperatures allow miners to operate at full capacity, maximizing computational output.

- Reduced Maintenance Costs: Lower operating temperatures reduce wear and tear on components, decreasing the frequency of repairs and replacements.

- Energy Savings: Efficient heat dissipation reduces the load on cooling systems, leading to significant reductions in power consumption.

These benefits highlight the practical value of the heat sink in real-world mining operations.

Conclusion

In the competitive world of cryptocurrency mining, every watt of power and every degree of temperature matters. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents a cutting-edge solution to the thermal challenges faced by mining operators. By enhancing heat dissipation, optimizing airflow, and maintaining consistent temperatures, it reduces thermal-induced power losses and improves overall system efficiency.

For mining operators looking to maximize their profitability and extend the lifespan of their hardware, investing in precision-engineered heat sinks is a strategic move. With its advanced thermal management capabilities and durable design, this heat sink is poised to become an essential component in modern mining rigs. Whether you’re running a small-scale operation or managing a large mining farm, integrating this heat sink into your setup can deliver tangible benefits that enhance both performance and profitability.