How does the thermal interface optimize heat transfer from ASIC miner components?

July 10, 2025

How Does the Thermal Interface Optimize Heat Transfer from ASIC Miner Components?

Cryptocurrency mining has evolved into a highly specialized industry where efficiency and reliability are paramount. At the heart of every mining operation lies the ASIC miner, a machine designed to perform complex cryptographic calculations at lightning speed. However, the intense computational workload generates significant heat, which, if not managed properly, can lead to reduced performance, hardware failure, and increased operational costs. This is where the thermal interface and heat sinks play a critical role in ensuring optimal heat transfer and thermal management. In this article, we’ll explore how the precision-engineered thermal interface and heat sinks optimize heat transfer from ASIC miner components, enhancing both performance and longevity.

The Role of Heat Sinks in ASIC Miner Thermal Management

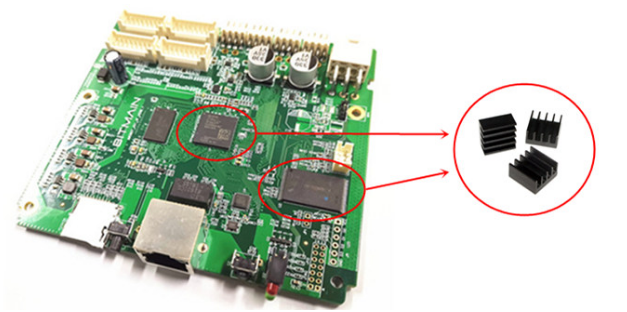

Heat sinks are essential components in any high-performance computing system, including ASIC miners. Their primary function is to dissipate heat generated by electronic components, such as CPUs and power management chips, to maintain safe operating temperatures. In the context of cryptocurrency mining, where ASIC miners operate continuously under heavy loads, effective heat dissipation is crucial to prevent thermal throttling and hardware degradation.

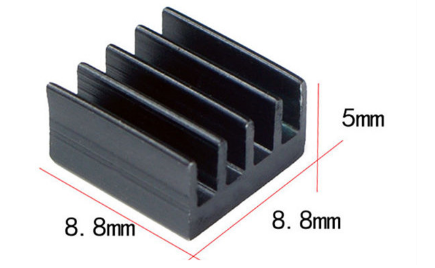

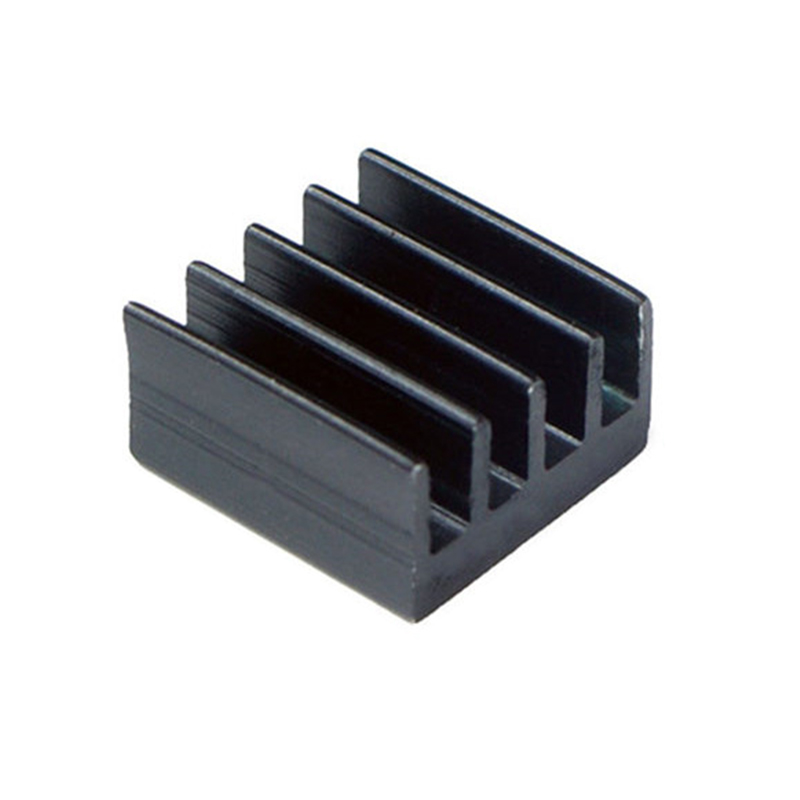

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a standout solution specifically designed for ASIC mining control boards. Crafted from high-grade aluminum alloy, this heat sink features an optimized multi-piece construction that maximizes thermal dissipation efficiency. Its compact form factor ensures it fits seamlessly into mining rigs without compromising on cooling performance. Weighing just 0.01 KG, this lightweight yet robust solution delivers exceptional thermal management while minimizing the spatial footprint of the control board assembly.

The Thermal Interface: Bridging the Gap Between Components and Heat Sinks

While heat sinks are vital, their effectiveness hinges on the thermal interface material (TIM) that bridges the gap between the heat-generating components and the heat sink surface. The TIM ensures optimal thermal conductivity, creating an efficient pathway for heat dissipation.

The specialized thermal interface material used in this system is a thermally conductive silica gel layer. This material is engineered to fill microscopic imperfections and air gaps between the component and the heat sink, ensuring maximum contact area and heat transfer efficiency. By optimizing the thermal interface, the system minimizes thermal resistance, allowing heat to flow more effectively from the component to the heat sink.

Key Advantages of Optimized Thermal Interface and Heat Sinks

1. Optimized Spatial Efficiency

The precision-engineered dimensions of the heat sink (8.8mm × 8.8mm × 5mm) ensure it fits perfectly within the confined spaces of mining rigs. This compact design maximizes cooling performance while minimizing the spatial footprint, allowing miners to optimize their rig layouts without sacrificing thermal management capabilities.

2. Advanced Thermal Management

By maintaining consistent temperature control at critical device nodes, this heat sink solution prevents thermal throttling and extends the lifespan of ASIC miner components. The efficient heat dissipation ensures that components operate well within their specified thermal limits, enhancing overall system stability and reliability.

3. Enhanced Power Efficiency

Effective thermal management reduces thermal-induced power losses, improving the overall energy efficiency of the mining operation. This translates to lower electricity costs and a reduced environmental footprint, making the system both economically and environmentally sustainable.

4. Environmental Control Excellence

The multi-piece design of the heat sink facilitates strategic airflow management and efficient heat distribution. This creates an optimized microenvironment around critical components, ensuring they remain cool even during prolonged mining sessions.

5. Durability-Focused Design

Constructed from premium aluminum alloy, the heat sink is built to withstand the rigors of continuous mining operations. Its robust design ensures long-term reliability and consistent thermal performance, even under high-temperature conditions.

6. Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency. This ensures consistent thermal conductivity across the entire contact area, enhancing the overall effectiveness of the cooling solution.

7. Installation Versatility

Designed for compatibility with various control board configurations, the heat sink ensures optimal thermal contact across different mining hardware setups. This versatility makes it a valuable addition to any mining operation, regardless of the specific ASIC miner model.

Real-World Applications and Operational Insights

In practical terms, the integration of an optimized thermal interface and heat sink system can significantly improve the performance and longevity of ASIC miners. For example, in a large-scale mining farm operating thousands of ASIC miners, even a slight reduction in operating temperatures can lead to substantial energy savings and reduced hardware failure rates. By maintaining consistent thermal regulation, miners can avoid costly downtime and maximize their return on investment.

Moreover, the compact and lightweight design of the heat sink allows miners to optimize their rig layouts, accommodating more machines within a given space. This is particularly valuable in high-density mining setups, where space is at a premium.

Conclusion: A Game-Changer for ASIC Miner Thermal Management

The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink and specialized thermal interface material represent a game-changing solution for ASIC miner thermal management. By optimizing heat transfer from critical components, this system ensures consistent temperature control, enhanced power efficiency, and extended hardware lifespan. Its compact design, durability, and installation versatility make it an indispensable tool for cryptocurrency mining operations seeking to maximize efficiency and reliability.

In an industry where every watt of power and every degree of temperature matters, investing in advanced thermal management solutions like this heat sink and thermal interface is a smart move for any mining operator. Whether you’re running a small-scale mining rig or managing a large-scale farm, these components can help you achieve optimal performance and protect your valuable ASIC mining hardware from the damaging effects of heat.