How does using the right heat sink protect ASIC miner components from heat damage?

March 8, 2025

How Does Using the Right Heat Sink Protect ASIC Miner Components from Heat Damage?

Cryptocurrency mining has evolved into a highly technical and competitive field, where the efficiency and longevity of mining hardware can make or break profitability. At the heart of this operation lies the ASIC (Application-Specific Integrated Circuit) miner, a specialized device designed to solve complex cryptographic algorithms. However, the intense computational workload generates significant heat, which, if not managed properly, can lead to component failure and reduced operational lifespan. This is where the right heat sink comes into play. In this article, we’ll explore how using a precision-engineered heat sink, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, protects ASIC miner components from heat damage and ensures optimal performance.

The Role of Heat Sinks in ASIC Mining Operations

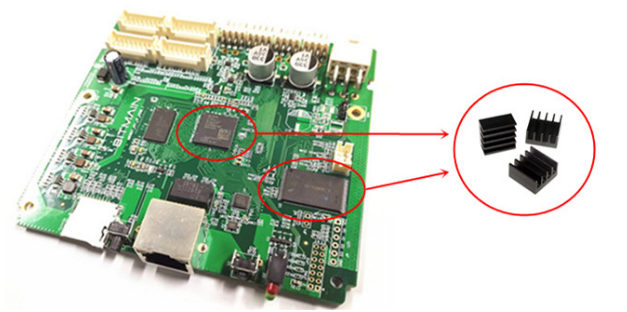

ASIC miners are designed to operate at peak efficiency, but the constant processing of complex algorithms generates substantial heat. This heat primarily originates from the control board’s CPU, power management chips, and other critical components. Without effective thermal management, these components can overheat, leading to thermal throttling, reduced performance, and even permanent damage.

A heat sink is a passive cooling device that absorbs and dissipates heat away from these critical components. By providing a larger surface area for heat to spread and transferring it to the surrounding air, heat sinks help maintain stable operating temperatures. However, not all heat sinks are created equal. The design, material, and integration of the heat sink play a crucial role in its effectiveness.

Introducing the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

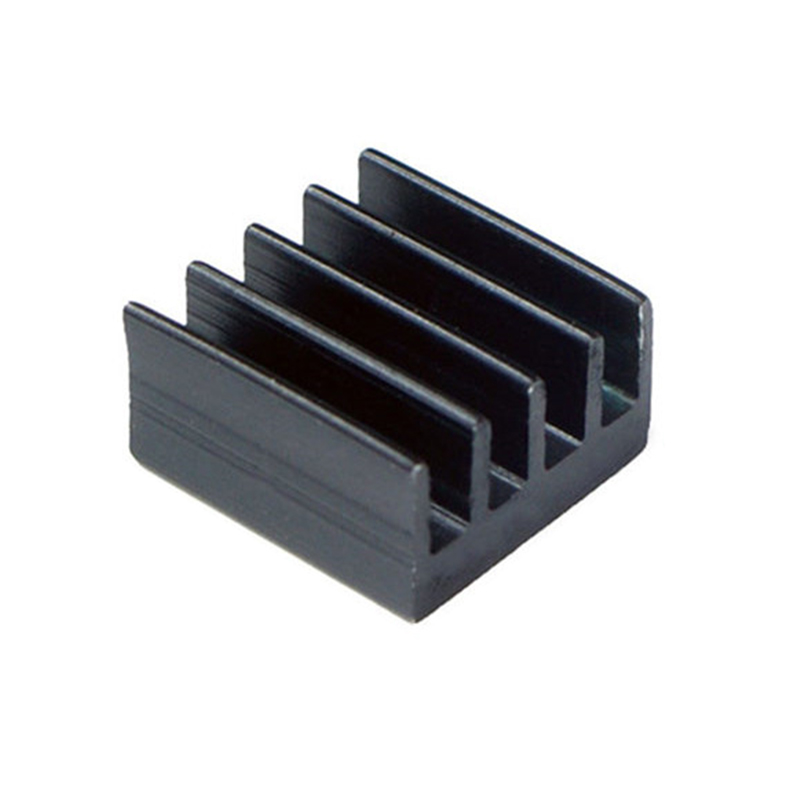

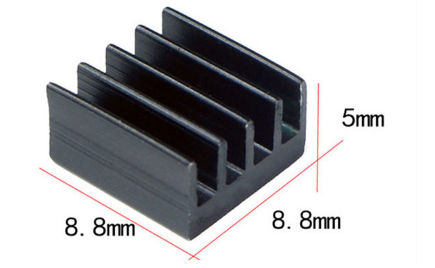

The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution specifically designed for ASIC mining control boards. Its compact dimensions and lightweight construction make it an ideal choice for modern mining rigs, where space and weight are often at a premium.

Technical Architecture

Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction optimized for maximum thermal dissipation efficiency. The design incorporates advanced thermal engineering principles to facilitate rapid heat transfer from critical components, such as CPUs and power management chips, to the heat sink surface. This ensures that heat is effectively removed before it can cause damage.

Thermal Interface Integration

One of the standout features of this heat sink is its integration with specialized thermal interface material (TIM). This thermally conductive silica gel layer enhances the heat transfer efficiency between the heat-generating components and the heat sink surface. By creating an efficient thermal pathway, the TIM ensures that heat is quickly and evenly distributed across the heat sink, preventing hot spots and maintaining consistent temperatures.

Advantages of the Right Heat Sink for ASIC Mining

Using the right heat sink offers several key advantages that directly translate to improved performance and longevity of ASIC mining hardware. Let’s delve into the specific benefits of this precision-engineered solution.

1. Optimized Spatial Efficiency

Mining rigs are often densely packed with hardware, leaving little room for additional components. The 8.8mm × 8.8mm × 5mm dimensions of this heat sink are carefully calculated to maximize cooling performance while minimizing its spatial footprint. This allows miners to maintain optimal thermal management without sacrificing valuable space.

2. Advanced Thermal Management

Superior temperature control is critical for preventing thermal throttling and extending the lifespan of mining components. This heat sink excels at maintaining optimal operating conditions, ensuring that critical components remain well within their specified thermal limits. By preventing overheating, it reduces the risk of performance degradation and hardware failure.

3. Enhanced Power Efficiency

Heat can lead to increased power consumption and reduced efficiency in ASIC miners. By efficiently dissipating heat, this heat sink minimizes thermal-induced power losses, resulting in improved overall system efficiency. This translates to lower operating costs and higher profitability for mining operations.

4. Environmental Control Excellence

The multi-piece design of this heat sink facilitates strategic airflow management and efficient heat distribution. By creating an optimized microenvironment around critical components, it ensures that heat is evenly dispersed and effectively removed from the system. This contributes to a more stable and reliable mining environment.

5. Durability-Focused Design

Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous high-temperature operations. Its robust design ensures long-term reliability and consistent thermal performance, even under the most demanding conditions.

6. Thermal Interface Optimization

The heat sink’s compatibility with thermal interface materials maximizes heat transfer efficiency, ensuring consistent thermal conductivity across the entire contact area. This optimization is crucial for maintaining steady-state temperature control in high-performance mining operations.

7. Installation Versatility

Designed for compatibility with various control board configurations, this heat sink offers installation versatility without compromising on thermal contact. Its adaptability makes it a practical solution for a wide range of mining hardware setups.

Real-World Applications and Operational Insights

In practical terms, integrating the right heat sink into your ASIC mining setup can yield significant benefits. For example, in a high-density mining farm where multiple rigs operate simultaneously, effective thermal management is essential to prevent overheating and ensure consistent performance. The 8.8mm × 8.8mm × 5mm heat sink’s compact design and superior cooling capabilities make it an ideal choice for such environments.

Moreover, the use of thermal interface material enhances the heat sink’s effectiveness, ensuring that heat is efficiently transferred away from critical components. This is particularly important for power management chips, which are prone to overheating due to their high energy consumption. By maintaining optimal temperatures, the heat sink helps prevent thermal throttling and extends the lifespan of these components.

Conclusion: Protecting Your Investment with the Right Heat Sink

In the world of cryptocurrency mining, every component plays a crucial role in ensuring the efficiency and longevity of your hardware. Heat sinks may seem like a small part of the equation, but their impact on thermal management cannot be overstated. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, with its advanced design and superior performance, offers a practical and effective solution for protecting ASIC miner components from heat damage.

By investing in the right heat sink, you can optimize your mining operations, reduce operating costs, and extend the lifespan of your hardware. Whether you’re running a small-scale mining setup or managing a large-scale mining farm, this precision-engineered heat sink is a valuable addition to your toolkit. Don’t let heat damage compromise your mining efficiency—choose the right heat sink and keep your ASIC miners running at their best.