How does using the right heat sink protect ASIC miner components from heat damage?

July 20, 2025

How Does Using the Right Heat Sink Protect ASIC Miner Components from Heat Damage?

Cryptocurrency mining is a resource-intensive process that generates significant heat, particularly in ASIC (Application-Specific Integrated Circuit) miners. These devices are engineered for maximum efficiency in solving cryptographic algorithms, but their high-performance nature comes with a critical challenge: managing heat. Without proper thermal management, ASIC miner components—especially control boards and chips—can suffer from heat damage, leading to reduced performance, hardware failure, or even permanent damage. This is where the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink steps in as a game-changing solution.

In this article, we’ll explore how the right heat sink protects ASIC miner components from heat damage, diving into its design, advantages, and real-world applications. Whether you’re a seasoned mining operator or a newcomer to the cryptocurrency space, understanding the role of thermal management in mining hardware is essential for optimizing performance and ensuring long-term profitability.

The Importance of Thermal Management in ASIC Mining

ASIC miners are designed to operate at peak efficiency, but this efficiency comes at a cost: heat generation. The control board and its associated chips are particularly vulnerable to overheating, as they handle the computational workload and power distribution within the miner. When temperatures exceed safe operating limits, several issues can arise:

- Thermal Throttling: To prevent damage, ASIC miners may reduce their processing speed, resulting in lower hash rates and diminished mining performance.

- Component Degradation: Prolonged exposure to high temperatures can degrade sensitive electronic components, shortening their lifespan.

- Hardware Failure: In extreme cases, overheating can cause irreversible damage, leading to costly repairs or replacements.

Effective thermal management is therefore critical to maintaining optimal performance and protecting your investment in mining hardware.

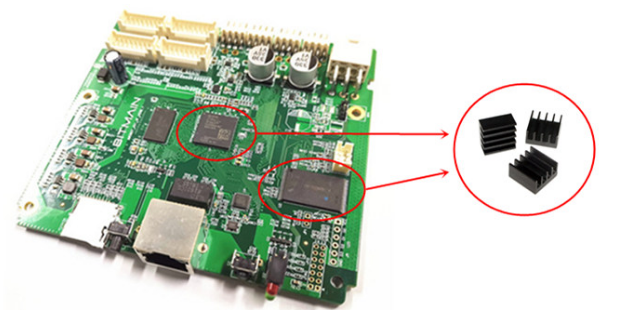

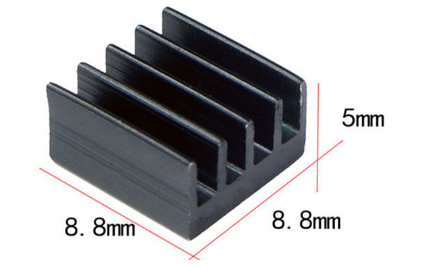

Introducing the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a purpose-built solution designed specifically for ASIC mining control boards. Its compact yet highly efficient design addresses the unique thermal challenges of cryptocurrency mining operations. Let’s break down its key features and how they contribute to protecting ASIC miner components.

#### Optimized Spatial Efficiency One of the standout features of this heat sink is its compact dimensions. Measuring just 8.8mm × 8.8mm × 5mm, it maximizes cooling performance without encroaching on valuable space within the mining rig. This is particularly important in densely packed setups, where every millimeter counts. The heat sink’s small footprint ensures it can be seamlessly integrated into various control board configurations without disrupting airflow or component placement.

#### Advanced Thermal Management Crafted from high-grade aluminum alloy, this heat sink excels at dissipating heat from critical components like CPUs and power management chips. Its multi-piece construction is engineered to facilitate rapid heat transfer, maintaining temperatures well within safe limits. By preventing overheating, it helps avoid thermal throttling and extends the lifespan of your mining hardware.

#### Enhanced Power Efficiency Heat is a significant contributor to power losses in ASIC miners. The efficient heat dissipation provided by this heat sink reduces thermal-induced power losses, improving overall system efficiency. This translates to lower operating costs and higher profitability for your mining operation.

#### Environmental Control Excellence The heat sink’s design promotes strategic airflow management, creating an optimized microenvironment around critical components. By efficiently distributing heat, it ensures consistent cooling even in high-temperature environments. This is especially beneficial for large-scale mining operations where maintaining stable temperatures across multiple rigs is a challenge.

#### Durability-Focused Design Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous mining operations. Its robust design ensures long-term reliability, even under extreme conditions. This durability is crucial for mining operators who rely on their hardware to run 24/7 without interruption.

#### Thermal Interface Optimization The heat sink is engineered to work seamlessly with thermal interface materials (TIMs), such as thermally conductive silica gel. This ensures maximum heat transfer efficiency from the components to the heat sink surface. The result is consistent thermal conductivity, which is essential for maintaining steady-state temperature control.

#### Installation Versatility Whether you’re working with a single ASIC miner or managing a large-scale mining farm, this heat sink offers installation versatility. It’s compatible with a wide range of control board configurations, ensuring optimal thermal contact across different hardware setups.

Real-World Applications and Benefits

To truly appreciate the value of the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, let’s look at how it performs in real-world mining scenarios.

#### Preventing Thermal Throttling In high-performance mining environments, thermal throttling is a common issue that can significantly reduce hash rates. By effectively dissipating heat, this heat sink helps maintain optimal operating temperatures, preventing throttling and ensuring consistent mining performance.

#### Extending Component Lifespan Overheating is one of the primary causes of component degradation in ASIC miners. The heat sink’s superior thermal management capabilities protect sensitive components, extending their lifespan and reducing the need for frequent replacements.

#### Improving Energy Efficiency Heat dissipation directly impacts energy efficiency in mining operations. By minimizing thermal-induced power losses, this heat sink contributes to lower electricity costs, which is a major consideration for profitability in cryptocurrency mining.

#### Enhancing Operational Reliability For mining operators, downtime is costly. The durability and reliability of this heat sink ensure uninterrupted operation, even in demanding conditions. This peace of mind is invaluable for maintaining productivity and maximizing returns.

Installation Best Practices

To fully leverage the benefits of the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, proper installation is key. Here are some best practices to follow:

- Use High-Quality Thermal Interface Material: Apply a thin, even layer of thermally conductive silica gel to ensure optimal heat transfer between the component and the heat sink.

- Ensure Proper Alignment: Position the heat sink directly over the heat-generating component to maximize contact and heat dissipation.

- Secure Firmly: Use appropriate mounting hardware to ensure the heat sink remains firmly in place, even during vibration or movement.

- Monitor Temperatures: Regularly check the operating temperatures of your ASIC miner to confirm that the heat sink is performing as expected.

Conclusion: A Smart Investment for Mining Operators

In the competitive world of cryptocurrency mining, every advantage counts. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is more than just a cooling component—it’s a strategic investment in the longevity and efficiency of your mining hardware. By protecting ASIC miner components from heat damage, this heat sink ensures consistent performance, reduces operating costs, and enhances overall profitability.

Whether you’re running a small home setup or managing a large-scale mining farm, incorporating this advanced thermal management solution into your operation is a decision that pays dividends. Don’t let heat compromise your mining success—equip your ASIC miners with the right heat sink and keep your operation running cool and efficient.