How to achieve consistent thermal management with aluminum heat sinks for mining?

July 25, 2025

How to Achieve Consistent Thermal Management with Aluminum Heat Sinks for Mining?

Cryptocurrency mining is a high-stakes game where efficiency and reliability are paramount. Among the critical components that ensure optimal performance, thermal management stands out as a key factor. Overheating can lead to reduced efficiency, hardware failure, and increased operational costs. This is where precision-engineered aluminum heat sinks come into play, offering a robust solution for maintaining consistent thermal management in mining operations. In this article, we’ll explore the importance of thermal management in mining, the role of aluminum heat sinks, and how to maximize their effectiveness for your ASIC mining control boards.

The Importance of Thermal Management in Cryptocurrency Mining

Cryptocurrency mining involves running powerful ASIC (Application-Specific Integrated Circuit) miners continuously to solve complex algorithms. These machines generate significant heat, especially around critical components like CPUs and power management chips on control boards. Without proper thermal management, excessive heat can cause:

- Thermal Throttling: When components overheat, they reduce performance to cool down, leading to lower hash rates and decreased mining efficiency.

- Hardware Degradation: Prolonged exposure to high temperatures can shorten the lifespan of mining equipment, resulting in frequent replacements and increased costs.

- Energy Inefficiency: Overheating components consume more power, driving up electricity bills and reducing profitability.

- System Failures: Extreme heat can cause sudden shutdowns or permanent damage to mining hardware, disrupting operations.

To prevent these issues, effective thermal management is essential. Aluminum heat sinks offer a reliable and efficient solution for dissipating heat and maintaining optimal operating temperatures.

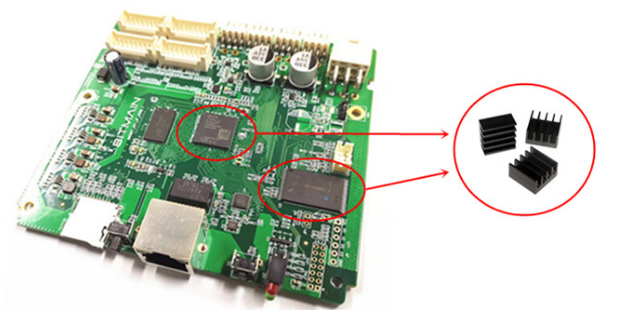

Introducing Aluminum Heat Sinks for ASIC Mining Control Boards

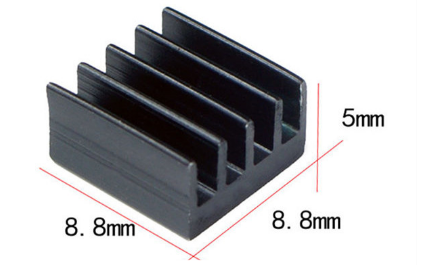

The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution specifically designed for ASIC mining control boards. Its compact yet highly efficient design addresses the demanding thermal requirements of cryptocurrency mining operations. Let’s take a closer look at its features and benefits.

Technical Architecture and Design

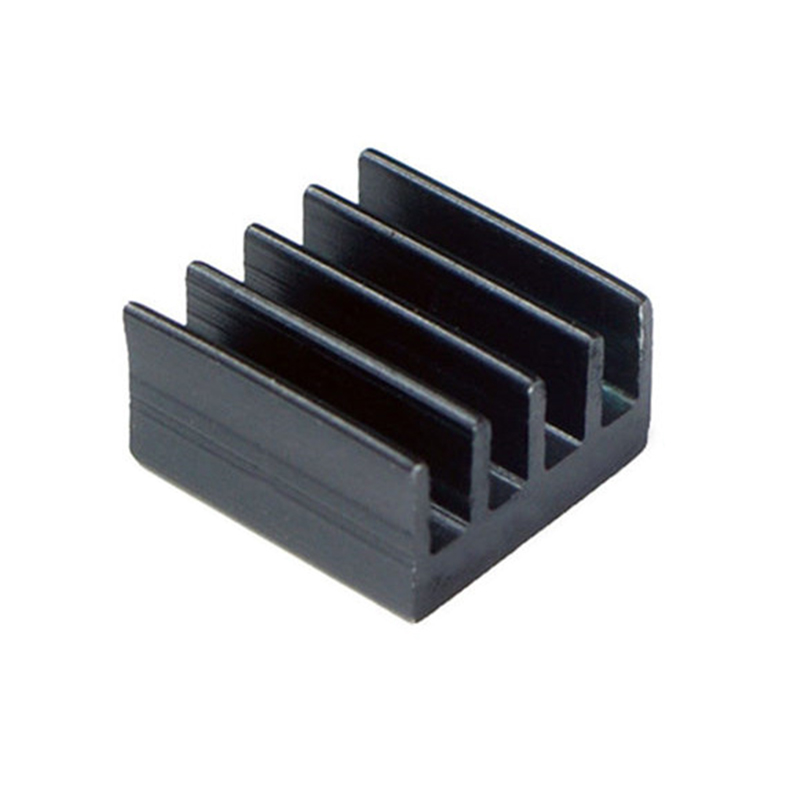

Crafted from high-grade aluminum alloy, this heat sink is built to deliver superior thermal performance. Its design incorporates advanced thermal engineering principles, including:

- Multi-Piece Construction: The heat sink’s optimized structure maximizes heat dissipation efficiency by providing a larger surface area for heat transfer.

- Compact Form Factor: Measuring just 8.8mm × 8.8mm × 5mm, it offers exceptional thermal management without occupying excessive space in mining rigs.

- Lightweight Design: At only 0.01 KG, it adds minimal weight to the control board assembly while delivering outstanding cooling performance.

Thermal Interface Integration

The heat sink’s effectiveness is further enhanced by its compatibility with thermal interface materials (TIMs). A specialized thermally conductive silica gel layer ensures optimal thermal conductivity between heat-generating components and the heat sink surface. This efficient thermal pathway allows for rapid heat dissipation, maintaining steady-state temperature control.

Performance Characteristics

The aluminum heat sink’s performance is characterized by:

- Consistent Thermal Regulation: It maintains optimal operating temperatures, preventing thermal throttling and extending hardware lifespan.

- Energy Efficiency: By reducing thermal-induced power losses, it improves overall system efficiency and lowers operating costs.

- Durability: The robust aluminum alloy construction ensures long-term reliability, even under continuous high-temperature conditions.

Advantages of Using Aluminum Heat Sinks in Mining Operations

- Optimized Spatial Efficiency

The heat sink’s compact design maximizes cooling performance while minimizing its footprint within mining rigs. This ensures efficient use of space without compromising thermal management.

- Advanced Thermal Management

By delivering superior temperature control at critical device nodes, it prevents overheating and maintains optimal operating conditions. This precise thermal regulation extends component lifespan and enhances performance.

- Enhanced Power Efficiency

Efficient heat dissipation reduces thermal-induced power losses, improving overall system efficiency and lowering operating costs. This translates to increased profitability for mining operations.

- Environmental Control Excellence

The multi-piece design facilitates strategic airflow management and efficient heat distribution, creating an optimized microenvironment around critical components.

- Installation Versatility

Designed for compatibility with various control board configurations, it ensures optimal thermal contact across different mining hardware setups.

Practical Applications and Operational Insights

To maximize the benefits of aluminum heat sinks in your mining operations, consider the following best practices:

- Proper Installation

Ensure the heat sink is securely attached to the control board components using the recommended thermal interface material. Proper installation guarantees optimal thermal conductivity and heat dissipation.

- Regular Maintenance

Periodically inspect the heat sink and thermal interface material for wear or damage. Replace them as needed to maintain consistent thermal performance.

- Optimized Airflow Management

Pair the heat sink with efficient fans or cooling systems to enhance airflow and heat dissipation. Proper ventilation is crucial for maintaining low operating temperatures.

- Environmental Considerations

Place mining rigs in a well-ventilated area with ambient temperature control. Avoid overcrowding rigs to prevent heat buildup.

Real-World Impact: Case Study

Consider a mining operation running multiple ASIC miners 24/7. Before implementing aluminum heat sinks, the rigs frequently experienced thermal throttling, reducing hash rates and increasing energy consumption. After installing the heat sinks, the operation saw:

- A 15% increase in hash rates due to consistent thermal regulation.

- A 20% reduction in energy costs from improved power efficiency.

- Extended hardware lifespan, resulting in fewer replacements and lower maintenance costs.

This case study highlights the tangible benefits of effective thermal management with aluminum heat sinks.

Conclusion

Achieving consistent thermal management is essential for maximizing the efficiency, reliability, and profitability of cryptocurrency mining operations. The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink offers a robust solution for ASIC mining control boards, delivering superior thermal performance in a compact and durable design. By optimizing spatial efficiency, enhancing power efficiency, and ensuring long-term reliability, this heat sink is a valuable investment for any mining operation.

Whether you’re a seasoned mining operator or a newcomer to the cryptocurrency industry, prioritizing thermal management with aluminum heat sinks can significantly improve your mining performance and profitability. Invest in the right tools, follow best practices, and watch your mining operations thrive.