How to choose heat sinks that maximize spatial efficiency in mining rigs?

March 13, 2025

How to Choose Heat Sinks That Maximize Spatial Efficiency in Mining Rigs?

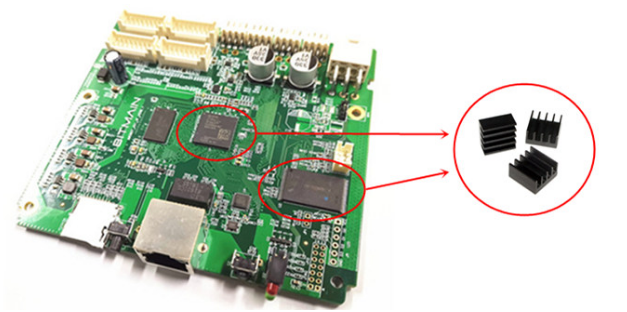

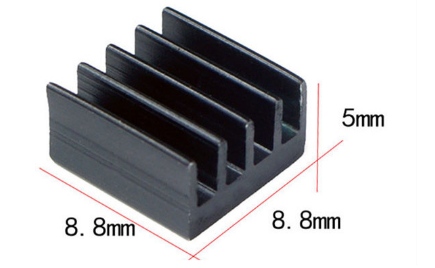

Cryptocurrency mining has evolved into a highly competitive and technically demanding industry. As miners strive to maximize their hash rates and profitability, the importance of efficient thermal management cannot be overstated. One of the most critical components in this regard is the heat sink, which plays a pivotal role in maintaining optimal temperatures for mining hardware. In this article, we’ll explore how to choose heat sinks that maximize spatial efficiency in mining rigs, with a focus on the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed specifically for ASIC miner control boards.

Understanding the Role of Heat Sinks in Mining Rigs

Mining rigs, especially those using ASIC (Application-Specific Integrated Circuit) miners, generate significant heat during operation. Excessive heat can lead to thermal throttling, reduced performance, and even hardware failure. Heat sinks are essential for dissipating this heat, ensuring that the mining hardware operates within safe temperature ranges.

The challenge for mining operators is twofold:

- Effective Heat Dissipation: Ensuring that heat is efficiently transferred away from critical components like CPUs and power management chips.

- Spatial Efficiency: Minimizing the footprint of cooling solutions to accommodate more hardware in limited space.

This is where the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink shines, offering a perfect balance of thermal performance and compact design.

Product Introduction: Precision-Engineered Heat Sinks for ASIC Miners

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution tailored for ASIC mining control boards. Its design focuses on addressing the unique challenges of cryptocurrency mining, where consistent temperature control directly impacts performance and hardware longevity.

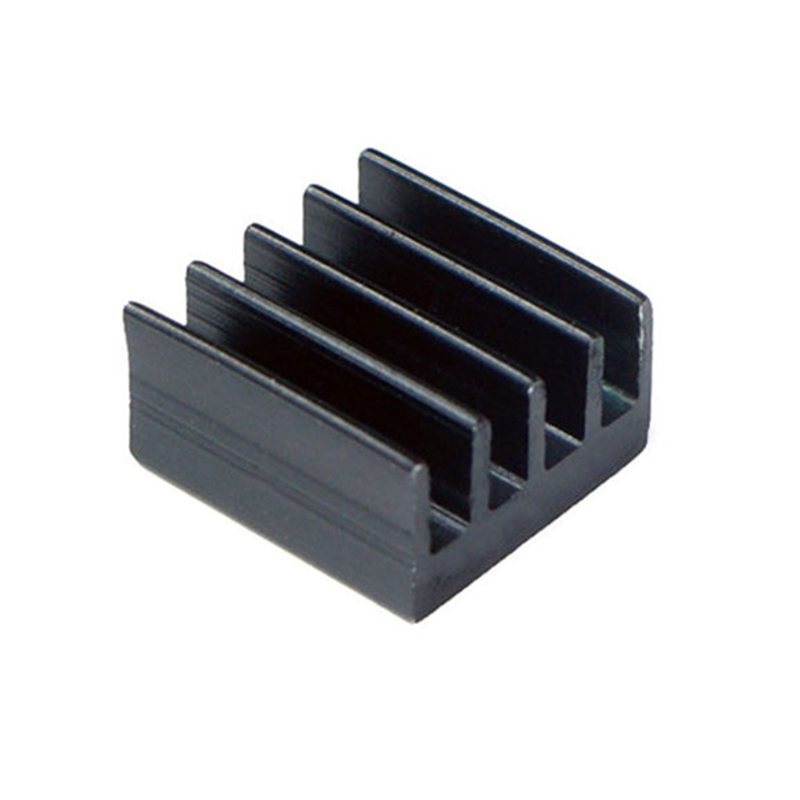

Technical Architecture

Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction that maximizes thermal dissipation efficiency. Its compact dimensions (8.8mm × 8.8mm × 5mm) and lightweight design (0.01 KG) ensure it doesn’t add unnecessary bulk to the control board assembly, making it ideal for densely packed mining rigs.

Thermal Interface Integration

The heat sink is engineered to work seamlessly with thermal interface materials (TIMs), such as thermally conductive silica gel. This ensures optimal thermal conductivity between the heat-generating components and the heat sink surface, creating an efficient pathway for heat dissipation.

Performance Characteristics

This heat sink delivers exceptional thermal performance while maintaining a minimal spatial footprint. Its precisely calculated design ensures consistent temperature control, crucial for maintaining optimal mining operations and protecting valuable ASIC hardware from thermal-induced degradation.

Product Advantages: Why This Heat Sink Stands Out

When selecting a heat sink for your mining rig, it’s essential to consider how its features translate into real-world benefits. Here’s why the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a standout choice:

1. Optimized Spatial Efficiency

Mining rigs often operate in confined spaces, and every millimeter counts. This heat sink’s compact dimensions (8.8mm × 8.8mm × 5mm) allow it to fit seamlessly into densely packed control boards without compromising on cooling performance. Its lightweight design also reduces strain on the control board, ensuring long-term reliability.

2. Advanced Thermal Management

The heat sink’s multi-piece construction and high-grade aluminum alloy material ensure superior heat dissipation. This translates to consistent temperature control at critical device nodes, preventing thermal throttling and extending the lifespan of your mining hardware.

3. Enhanced Power Efficiency

Efficient thermal management directly impacts power consumption. By reducing thermal-induced power losses, this heat sink helps improve overall system efficiency, lowering operating costs and boosting profitability.

4. Environmental Control Excellence

The heat sink’s design facilitates strategic airflow management and efficient heat distribution, creating an optimized microenvironment around critical components. This ensures that heat is evenly dispersed, preventing hot spots and maintaining stable operating conditions.

5. Durability-Focused Design

Mining operations are demanding, often running 24/7 under high-temperature conditions. The premium aluminum alloy construction ensures long-term reliability, maintaining consistent thermal performance even during extended mining sessions.

6. Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency. This ensures that the heat generated by components is quickly and effectively dissipated, maintaining optimal operating temperatures.

7. Installation Versatility

Compatible with various control board configurations, this heat sink offers installation flexibility without compromising thermal contact. This makes it suitable for a wide range of mining hardware setups, enhancing its applicability.

Practical Considerations for Choosing Heat Sinks

When selecting a heat sink for your mining rig, consider the following factors to ensure you maximize spatial efficiency and thermal performance:

1. Compatibility with Your Hardware

Ensure the heat sink is compatible with your ASIC miner’s control board design. The 8.8mm × 8.8mm × 5mm heat sink is versatile, making it suitable for various configurations.

2. Thermal Dissipation Capacity

Evaluate the heat sink’s ability to dissipate heat effectively. The multi-piece construction and high-grade aluminum alloy material of this heat sink ensure superior thermal performance.

3. Spatial Footprint

In densely packed mining rigs, every millimeter matters. The compact dimensions of this heat sink make it an ideal choice for maximizing spatial efficiency.

4. Ease of Installation

Look for heat sinks that are easy to install and integrate with thermal interface materials. The design of this heat sink ensures optimal thermal contact and straightforward installation.

5. Durability and Reliability

Mining operations are continuous and demanding. Choose heat sinks made from durable materials like aluminum alloy to ensure long-term reliability.

Real-World Applications and Benefits

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink has been successfully implemented in numerous mining operations, delivering tangible benefits:

- Reduced Downtime: Consistent temperature control minimizes the risk of hardware failure, reducing downtime and maximizing productivity.

- Increased Profitability: Enhanced power efficiency lowers operating costs, contributing to higher profitability.

- Extended Hardware Lifespan: Effective thermal management extends the lifespan of ASIC miners, protecting your investment.

Conclusion: A Smart Investment for Mining Operators

Choosing the right heat sink is a critical decision for mining operators looking to maximize spatial efficiency and thermal performance. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink offers an ideal solution, combining compact design, superior thermal management, and long-term reliability. By integrating this advanced cooling component into your mining rigs, you can ensure optimal performance, protect your hardware, and enhance your overall profitability.

In the competitive world of cryptocurrency mining, investing in precision-engineered heat sinks like this one is not just a smart choice—it’s a necessity. Equip your mining rigs with the best thermal management solutions and stay ahead in the game.