How to clean and maintain the aluminum cooling plates of Iceriver KS5L KS5M kit?

February 27, 2025

How to Clean and Maintain the Aluminum Cooling Plates of Iceriver KS5L/KS5M Kit?

Cryptocurrency mining is an intensive process that generates significant heat, making efficient thermal management crucial for maintaining hardware performance and longevity. The Iceriver KS5L/KS5M Water Cooling Plate Kit is a state-of-the-art solution designed specifically for Bitmain KS5L and KS5M miners. Its advanced aluminum cooling plates and integrated cooling system ensure optimal thermal efficiency, but like any high-performance equipment, proper cleaning and maintenance are essential to sustain its effectiveness.

In this article, we’ll explore practical steps and best practices for cleaning and maintaining the aluminum cooling plates of the Iceriver KS5L/KS5M kit, ensuring your mining operations remain efficient and reliable.

Why Maintenance Matters: The Role of Cooling Plates in Mining Efficiency

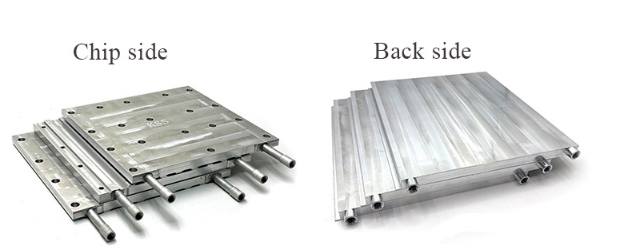

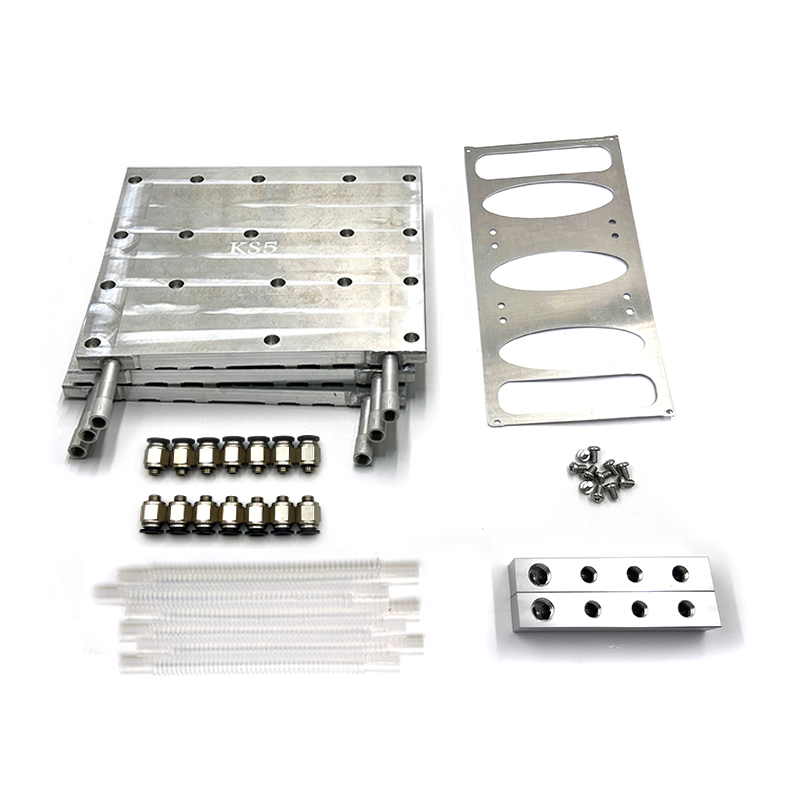

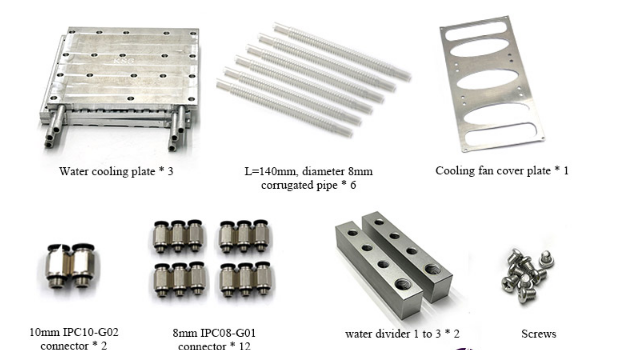

Before diving into the cleaning process, it’s important to understand why maintaining the cooling plates is critical. The Iceriver KS5L/KS5M kit features triple integrated aluminum water-cooling plates, which play a pivotal role in dissipating heat from the hash boards. These plates are engineered for superior thermal conductivity and corrosion resistance, but over time, dust, mineral deposits, and other contaminants can accumulate on their surfaces. This buildup can impair heat transfer, leading to higher operating temperatures, reduced mining efficiency, and potential hardware damage.

Regular cleaning and maintenance not only preserve the cooling plates’ performance but also extend the lifespan of your mining equipment, saving you significant costs in the long run.

Step-by-Step Guide to Cleaning the Aluminum Cooling Plates

1. Preparation: Safety and Tools

Before starting, ensure you have the following tools and materials:

- Soft-bristle brush or microfiber cloth

- Isopropyl alcohol (90% or higher)

- Distilled water

- Compressed air can or air blower

- Non-abrasive cleaning solution (optional)

- Protective gloves and safety goggles

Safety is paramount. Always disconnect the miner from the power source and allow it to cool completely before beginning the cleaning process.

2. Remove Dust and Debris

Start by using compressed air or an air blower to remove loose dust and debris from the cooling plates. Hold the air blower at a slight angle to avoid driving particles deeper into the system. Pay special attention to the gaps between the plates and around the connectors.

3. Wipe Down the Plates

Dampen a microfiber cloth with distilled water or a non-abrasive cleaning solution. Gently wipe the surfaces of the cooling plates to remove any remaining dust or light grime. Avoid using harsh chemicals or abrasive materials, as they can damage the aluminum surface.

For stubborn residues, use isopropyl alcohol on a soft-bristle brush. Alcohol evaporates quickly, leaving no residue and effectively dissolving grease or mineral deposits.

4. Clean the Corrugated Bellows

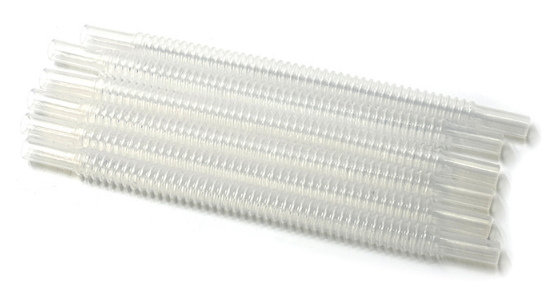

The Iceriver kit includes twelve corrugated bellows that ensure smooth coolant flow. These can accumulate debris over time, so clean them carefully using a soft brush and isopropyl alcohol. Ensure the bellows are completely dry before reassembly.

5. Inspect for Corrosion or Damage

While cleaning, inspect the cooling plates and other components for signs of corrosion, cracks, or wear. Early detection of these issues can prevent costly repairs or replacements. If you notice any damage, consult the manufacturer or a professional technician.

6. Reassemble and Test

Once cleaning is complete, reassemble the cooling system carefully. Double-check all connections, especially the 26 quick-connect fittings, to ensure they are secure and leak-free. Power up the miner and monitor its performance to confirm that the cooling system is functioning optimally.

Best Practices for Maintaining the Iceriver KS5L/KS5M Kit

1. Regular Cleaning Schedule

Establish a routine cleaning schedule based on your mining environment. For dusty or high-humidity locations, monthly cleaning may be necessary. In cleaner environments, quarterly maintenance may suffice.

2. Use High-Quality Coolant

The choice of coolant significantly impacts the cooling system’s performance and longevity. Use a high-quality, non-conductive coolant with anti-corrosion properties to minimize mineral buildup and protect the aluminum plates.

3. Monitor Temperature and Flow Rates

Install temperature sensors and flow meters to monitor the cooling system’s performance. Sudden spikes in temperature or reduced flow rates can indicate blockages or other issues that require attention.

4. Protect Against Environmental Contaminants

The Iceriver kit’s specialized cover plate provides excellent protection against dust and debris. However, additional measures such as air filters or environmental enclosures can further safeguard the system.

5. Keep Spare Parts On Hand

Having spare components like connectors, bellows, or even an extra cooling plate can minimize downtime in case of unexpected failures.

The Advantages of Proper Maintenance

By following these cleaning and maintenance practices, you can fully leverage the advantages of the Iceriver KS5L/KS5M Water Cooling Plate Kit:

- Enhanced Thermal Performance: Clean cooling plates maintain optimal heat dissipation, ensuring consistent mining efficiency.

- Extended Hardware Lifespan: Regular maintenance reduces wear and tear, prolonging the life of your mining equipment.

- Cost Savings: Preventing costly repairs and replacements translates to higher profitability in your mining operations.

- Operational Reliability: A well-maintained cooling system minimizes the risk of unexpected failures, ensuring uninterrupted mining.

Conclusion

The Iceriver KS5L/KS5M Water Cooling Plate Kit is a cutting-edge solution designed to maximize the efficiency and longevity of your mining hardware. However, its performance depends heavily on proper cleaning and maintenance. By incorporating the steps and best practices outlined in this article, you can ensure that your cooling system operates at peak efficiency, safeguarding your investment and maintaining your competitive edge in the cryptocurrency mining industry.

Remember, proactive maintenance is not just a chore—it’s a strategic approach to optimizing your mining operations and achieving long-term success.