How to clean and maintain the aluminum cooling plates of Iceriver KS5L KS5M kit?

May 28, 2025

How to Clean and Maintain the Aluminum Cooling Plates of Iceriver KS5L/KS5M Kit?

Cryptocurrency mining is a demanding operation that requires not only powerful hardware but also efficient thermal management systems to ensure sustained performance. The Iceriver KS5L/KS5M water cooling plate kit has emerged as a game-changer in this regard, offering a sophisticated solution for managing the heat generated by Bitmain KS5L and KS5M miners. However, like any high-performance system, proper cleaning and maintenance are crucial to maintaining its efficiency and longevity. In this article, we’ll explore the best practices for cleaning and maintaining the aluminum cooling plates of the Iceriver KS5L/KS5M kit, ensuring your mining operations run smoothly and efficiently.

Understanding the Iceriver KS5L/KS5M Water Cooling Plate Kit

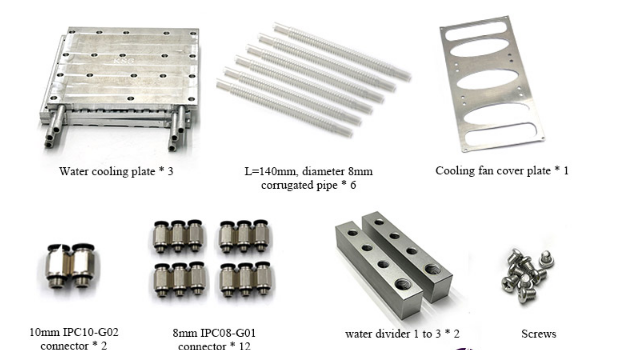

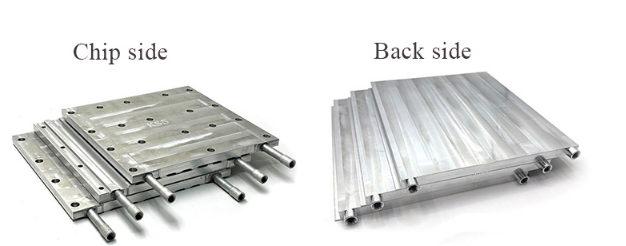

Before diving into maintenance, it’s essential to understand the components and design of the Iceriver KS5L/KS5M kit. This system is built around a triple-plate configuration made from high-quality aluminum, chosen for its excellent thermal conductivity and corrosion resistance. The plates are strategically positioned to maximize heat dissipation from the hash boards, ensuring optimal operating temperatures even under heavy workloads.

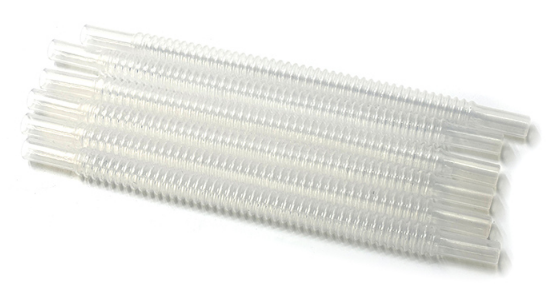

The kit also features a dual water separator design, which optimizes coolant distribution and flow dynamics. Twelve corrugated bellows accommodate thermal expansion, while 26 quick-connect connectors ensure a leak-proof and easy-to-install system. The integrated cover plate provides additional protection against environmental contaminants, making this kit a comprehensive solution for thermal management in mining operations.

Why Cleaning and Maintenance Are Critical

Over time, dust, debris, and mineral deposits can accumulate on the cooling plates and within the coolant channels. This buildup can impede heat transfer, reduce cooling efficiency, and potentially lead to overheating or hardware failure. Regular cleaning and maintenance not only prevent these issues but also extend the lifespan of your cooling system and mining equipment.

Step-by-Step Guide to Cleaning the Aluminum Cooling Plates

#### 1. Preparation Before starting, ensure the mining rig is powered off and disconnected from the power source. Allow the system to cool down completely to avoid burns or damage to components. Gather the necessary tools and materials, including:

- Soft-bristle brushes

- Isopropyl alcohol (90% or higher)

- Distilled water

- Compressed air

- Lint-free cloths

- A non-abrasive cleaning solution (optional)

#### 2. Disassembling the Cooling System Carefully disconnect the quick-connect fittings to remove the cooling plates from the miner. Follow the manufacturer’s instructions to avoid damaging the connectors or other components. Remove the cover plate and set aside all hardware for cleaning.

#### 3. Cleaning the Aluminum Plates

- Dry Cleaning: Use compressed air to blow away loose dust and debris from the cooling plates. Pay special attention to the fins and channels where buildup is most likely to occur.

- Wet Cleaning: Mix a small amount of non-abrasive cleaning solution with distilled water. Dip a soft-bristle brush into the solution and gently scrub the plates to remove stubborn dirt and mineral deposits. Avoid using harsh chemicals or abrasive materials that could damage the aluminum surface.

- Rinsing: Rinse the plates thoroughly with distilled water to remove any cleaning solution residue. Ensure no water remains in the channels or crevices.

- Drying: Use a lint-free cloth to dry the plates completely. Allow them to air dry for an additional 30 minutes to ensure no moisture remains.

#### 4. Cleaning the Coolant Channels If the coolant channels show signs of buildup, flush the system with a mixture of distilled water and isopropyl alcohol. This will help dissolve any mineral deposits and ensure smooth coolant flow. After flushing, rinse the system with distilled water and allow it to dry completely.

#### 5. Reassembling the System Once all components are clean and dry, reassemble the cooling system according to the manufacturer’s instructions. Ensure all connectors are securely fastened and the cover plate is properly installed to protect against contaminants.

Maintenance Tips for Long-Term Performance

- Regular Inspections: Schedule monthly inspections to check for dust buildup, leaks, or signs of corrosion. Address any issues promptly to prevent long-term damage.

- Coolant Quality: Use high-quality, non-conductive coolant to minimize mineral deposits and ensure efficient heat transfer. Replace the coolant as recommended by the manufacturer.

- Environmental Control: Keep the mining environment clean and free of dust. Consider using air filters or enclosures to reduce the amount of debris entering the cooling system.

- Thermal Monitoring: Monitor the temperature of your mining rig regularly. Sudden increases in temperature may indicate a problem with the cooling system that requires immediate attention.

- Professional Servicing: For complex issues or deep cleaning, consider hiring a professional technician with experience in mining equipment maintenance.

The Advantages of Proper Maintenance

By following these cleaning and maintenance practices, you can maximize the benefits of the Iceriver KS5L/KS5M water cooling plate kit:

- Enhanced Cooling Efficiency: Clean cooling plates and channels ensure optimal heat dissipation, reducing the risk of overheating and hardware failure.

- Extended Hardware Lifespan: Regular maintenance prevents corrosion and wear, prolonging the life of both the cooling system and the mining equipment.

- Cost Savings: Preventing costly repairs and downtime through proactive maintenance can significantly reduce operational expenses.

- Consistent Performance: A well-maintained cooling system ensures stable mining operations, maximizing your return on investment.

Conclusion

The Iceriver KS5L/KS5M water cooling plate kit is a powerful tool for managing the thermal demands of high-performance mining operations. However, its effectiveness depends on proper cleaning and maintenance. By incorporating these practices into your routine, you can ensure your cooling system operates at peak efficiency, safeguarding your mining hardware and optimizing your profitability. Remember, in the world of cryptocurrency mining, prevention is always better than cure—so take the time to care for your equipment, and it will reward you with reliable, long-lasting performance.