How to ensure optimal thermal contact with ASIC miner heat sinks?-ASIC miner control board/chip’s heat sinks

December 16, 2024

How to Ensure Optimal Thermal Contact with ASIC Miner Heat Sinks

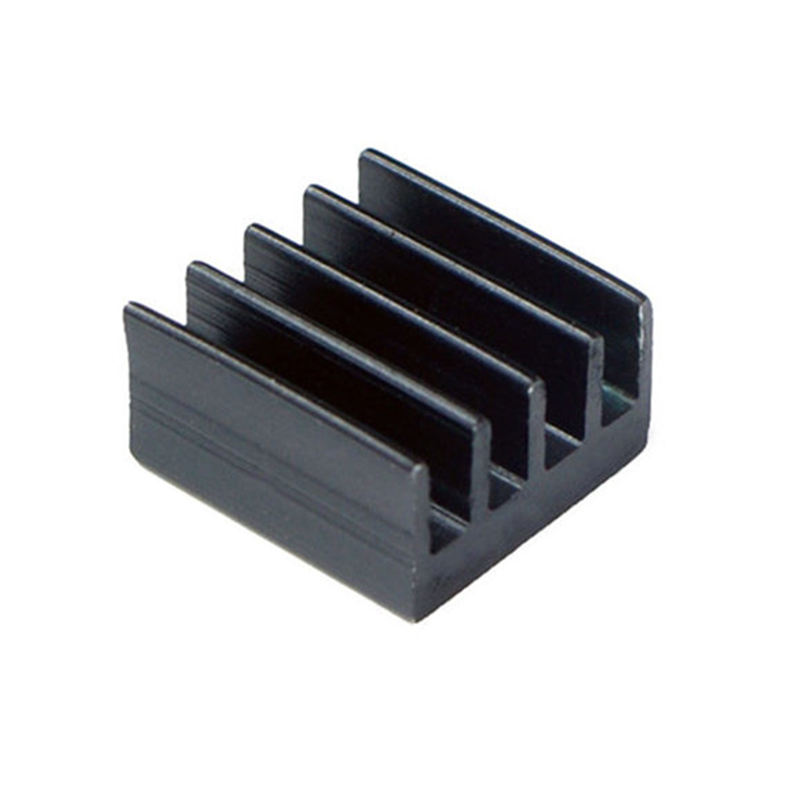

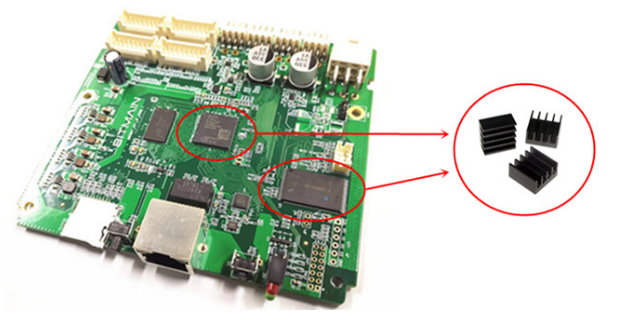

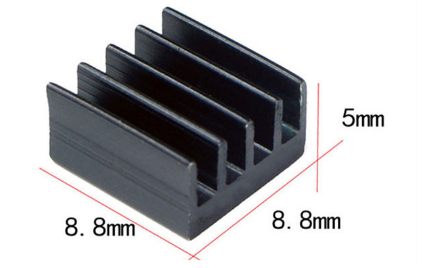

In the dynamic and fast-paced world of cryptocurrency mining, ensuring the efficient thermal management of our ASIC mining rigs is paramount to maintaining optimal performance and prolonging the lifespan of our valuable hardware investments. As an experienced user of the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed specifically for ASIC mining control board applications, I can attest to the critical role this advanced cooling component plays in the successful operation of my mining setup.

This heat sink represents a meticulously crafted thermal management solution that addresses the demanding thermal requirements of cryptocurrency mining operations. Crafted from high-grade aluminum alloy, its optimized multi-piece construction maximizes thermal dissipation efficiency, facilitating rapid heat transfer from critical components such as CPUs and power management chips on the mining control boards.

One of the key features that sets this heat sink apart is the implementation of a specialized thermal interface material (TIM) layer. This thermally conductive silica gel interface ensures optimal thermal conductivity between the heat-generating components and the heat sink surface, creating an efficient thermal pathway for heat dissipation. This integration of the TIM layer is crucial in maintaining the optimal thermal contact necessary for effective heat transfer, a critical aspect that I have found to be instrumental in the success of my mining operations.

The compact form factor of this heat sink, measuring just 8.8mm × 8.8mm × 5mm and weighing a mere 0.01 KG, is a testament to the engineering prowess behind its design. Despite its diminutive size, this heat sink delivers exceptional thermal performance without adding significant mass to the control board assembly, allowing for seamless integration into my mining rigs without compromising on valuable space.

One of the most impressive aspects of this heat sink solution is its ability to provide consistent thermal regulation for control board components, even under the demanding conditions of continuous mining operations. This steady-state temperature control is crucial for maintaining optimal mining performance and protecting my valuable ASIC mining hardware from thermal-induced degradation.

As an avid cryptocurrency miner, I have experienced firsthand the importance of maintaining optimal thermal management in my mining setup. Inadequate cooling can lead to thermal throttling, reduced mining efficiency, and, in the worst-case scenario, premature hardware failure. This is why I have come to rely on the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink as a critical component in my mining rigs.

The advanced thermal management capabilities of this heat sink have been instrumental in ensuring the consistent and reliable operation of my mining equipment. The optimized spatial efficiency, with its carefully calculated dimensions, allows for seamless integration into my mining rigs without compromising on available space. This is a crucial consideration, as mining setups often have limited physical footprints, and maximizing the use of available space is essential for achieving optimal performance and scalability.

One of the standout features of this heat sink is its ability to maintain optimal operating conditions for my ASIC mining components. By effectively dissipating heat and regulating temperatures, it helps prevent thermal throttling, a common issue that can significantly impact mining performance and efficiency. This precise thermal regulation has been a game-changer, as it not only maintains the consistent power delivery to my critical mining components but also extends the overall lifespan of my valuable hardware investments.

Furthermore, the heat sink’s environmental control excellence plays a crucial role in the overall efficiency of my mining operations. The strategic airflow management and efficient heat distribution created by the multi-piece design facilitate improved air circulation and heat displacement, ensuring an optimized microenvironment around the critical mining components. This, in turn, contributes to enhanced power efficiency, as the reduced thermal-induced power losses lead to lower operating costs and improved profitability.

The durability-focused design of this heat sink is another aspect that has truly impressed me. The premium aluminum alloy construction ensures long-term reliability and consistent thermal performance throughout the extended mining operations I subject my rigs to. This robust design maintains structural integrity even under continuous high-temperature conditions, giving me the peace of mind that my mining hardware is protected from thermal-induced degradation.

One of the key advantages of this heat sink solution is its seamless integration with thermal interface materials. The engineering team has meticulously optimized the heat sink’s design to work in harmony with these specialized TIMs, maximizing heat transfer efficiency from the components to the heat sink surface. This optimization ensures consistent thermal conductivity across the entire contact area, further enhancing the overall thermal management capabilities of my mining setup.

The installation versatility of this heat sink is another factor that has made it an indispensable component in my mining operations. Designed for compatibility with various control board configurations, it maintains optimal thermal contact while ensuring widespread applicability across different mining hardware setups. This flexibility has allowed me to streamline the integration process and ensure consistent thermal performance across my diverse mining rig portfolio.

As an experienced cryptocurrency miner, I have come to appreciate the crucial role that effective thermal management plays in the overall success and longevity of my mining operations. The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink has proven to be an invaluable asset in my pursuit of maintaining optimal mining performance and protecting my valuable ASIC hardware investments.

Through its advanced thermal management capabilities, optimized spatial efficiency, and seamless integration with thermal interface materials, this heat sink has become an integral part of my mining setup. The consistent temperature control, enhanced power efficiency, and long-term durability it provides have been instrumental in maximizing the profitability and reliability of my cryptocurrency mining endeavors.

In conclusion, as a seasoned cryptocurrency miner, I can confidently recommend the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink as a critical component for ensuring optimal thermal management in ASIC mining operations. Its exceptional performance, versatility, and engineering excellence have proven to be essential in maintaining the consistent and efficient operation of my mining rigs, ultimately contributing to the overall success and profitability of my cryptocurrency mining business.

|

Please feel free to contact me to assist you in resolving your issues: E-mail: Minerfixessales@gmail.com WhatsApp/WeChat:+86 15928044684

The services we offer include:

a.New and Used Miners b.Miner Accessories c.Miner Repair Courses d.Global Repair Stations e.Overclocking and Underclocking Services |

|