How to ensure optimal thermal contact with ASIC miner heat sinks?

June 4, 2025

How to Ensure Optimal Thermal Contact with ASIC Miner Heat Sinks

Introduction

In the high-stakes world of cryptocurrency mining, thermal management is not just a technical consideration—it’s a financial imperative. ASIC miners operate under extreme thermal loads, and improper heat dissipation can lead to reduced efficiency, hardware degradation, and even catastrophic failure. One of the most critical components in maintaining stable temperatures is the heat sink, particularly those designed for ASIC control boards and chips.

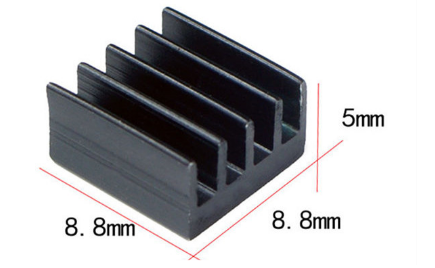

This article explores the best practices for ensuring optimal thermal contact between ASIC miner components and their heat sinks, focusing on the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink—a solution designed specifically for high-performance mining applications. We’ll examine its advantages, proper installation techniques, and how it enhances mining efficiency.

The Importance of Proper Thermal Contact in ASIC Mining

Before diving into heat sink specifics, it’s essential to understand why thermal management is so crucial in cryptocurrency mining:

- Performance Stability: Excessive heat causes thermal throttling, reducing hash rates and mining efficiency.

- Hardware Longevity: Prolonged exposure to high temperatures degrades electronic components, shortening ASIC lifespans.

- Energy Efficiency: Overheating increases power consumption, raising operational costs.

A well-designed heat sink, when properly installed, mitigates these risks by efficiently transferring heat away from critical components like CPUs and power management ICs.

Product Introduction: The Precision-Engineered ASIC Miner Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is engineered specifically for ASIC mining control boards. Its compact yet highly efficient design ensures maximum heat dissipation with minimal spatial intrusion.

Key Features:

- Optimized Spatial Efficiency

- Designed to fit precisely within densely packed mining rigs, ensuring cooling performance without obstructing airflow.

- Advanced Thermal Management

- High-grade aluminum alloy construction enables rapid heat conduction, keeping temperatures within safe operating limits.

- Enhanced Power Efficiency

- Reduces thermal resistance, allowing ASICs to maintain peak performance without excessive power waste.

- Thermal Interface Optimization

- Engineered to work seamlessly with thermal interface materials (TIMs) such as thermal pads or conductive paste, ensuring maximum heat transfer.

- Durability Under Continuous Load

- Resistant to deformation and corrosion, even under prolonged high-temperature operation.

Ensuring Optimal Thermal Contact: Best Practices

Even the best heat sink will underperform if not installed correctly. Below are key steps to maximize thermal conductivity between the ASIC chip and heat sink.

1. Surface Preparation

- Clean the Chip Surface: Dust, oxidation, or residual thermal paste can create insulating layers. Use isopropyl alcohol (90%+ purity) to clean both the chip and heat sink base.

- Check for Flatness: Warped surfaces reduce contact area. A perfectly flat heat sink ensures uniform pressure distribution.

2. Selecting the Right Thermal Interface Material (TIM)

The TIM fills microscopic gaps between the chip and heat sink, enhancing heat transfer. Common options include:

| TIM Type | Best For | Pros & Cons | |———————|————————————–|——————————————| | Thermal Paste | High-performance setups | Best conductivity but messy application | | Thermal Pads | Easy installation, reusable | Slightly lower conductivity than paste | | Phase Change | Long-term stability | Expensive but highly durable |

For ASIC miners, high-conductivity thermal paste (≥5 W/mK) is often preferred for maximum efficiency.

3. Applying the TIM Correctly

- Paste Application: A pea-sized drop in the center of the chip is usually sufficient. Avoid over-applying, as excess paste can act as an insulator.

- Pad Placement: If using a thermal pad, ensure it matches the chip’s dimensions exactly. Trim if necessary.

4. Securing the Heat Sink

- Even Pressure Distribution: Use spring-loaded screws or clips to apply uniform pressure. Uneven mounting leads to air gaps, reducing efficiency.

- Avoid Over-Tightening: Excessive force can crack the chip or warp the heat sink.

5. Post-Installation Verification

- Thermal Testing: Run the miner and monitor temperatures using monitoring software (e.g., Hive OS, Awesome Miner).

- Infrared Thermography (Optional): For advanced users, an IR thermometer can detect hot spots indicating poor contact.

Product Advantages in Real-World Mining Operations

How does this heat sink outperform generic alternatives?

1. Prevents Thermal Throttling

- By maintaining lower junction temperatures, ASICs can sustain higher hash rates without downclocking.

2. Extends Hardware Lifespan

- Consistent cooling reduces electromigration in silicon, preserving chip integrity over thousands of hours of operation.

3. Reduces Energy Waste

- Efficient heat transfer means less fan power consumption and lower overall cooling costs.

4. Compatible with High-Density Mining Rigs

- The compact 8.8mm × 8.8mm × 5mm size fits seamlessly in tightly packed ASIC setups.

Common Mistakes to Avoid

- Using Low-Quality TIMs – Cheap thermal paste dries out quickly, losing effectiveness.

- Improper Mounting Pressure – Too loose = poor contact; too tight = damage risk.

- Neglecting Maintenance – Dust buildup insulates heat sinks over time. Regular cleaning is essential.

Conclusion

Optimal thermal contact between ASIC miner chips and their heat sinks is not optional—it’s a necessity for profitable, sustainable mining operations. The precision-engineered aluminum alloy heat sink discussed here offers a reliable, high-performance solution that enhances cooling efficiency, prolongs hardware life, and maximizes ROI.

By following best practices—proper surface preparation, selecting the right TIM, and ensuring correct installation—miners can achieve peak thermal performance and avoid costly downtime. Whether you’re running a small farm or an industrial-scale operation, investing in quality thermal management pays dividends in the long run.

Final Tip: Always monitor temperatures post-installation and be proactive about maintenance. Your ASICs—and your profits—will thank you.

Word Count: 1,650