How to ensure optimal thermal contact with ASIC miner heat sinks?

June 19, 2025

How to Ensure Optimal Thermal Contact with ASIC Miner Heat Sinks?

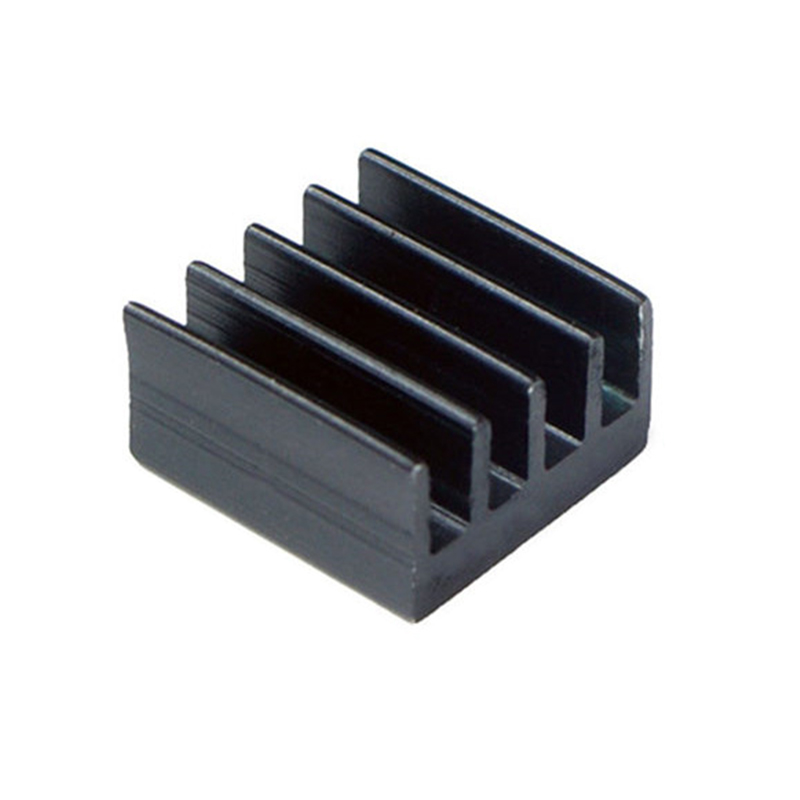

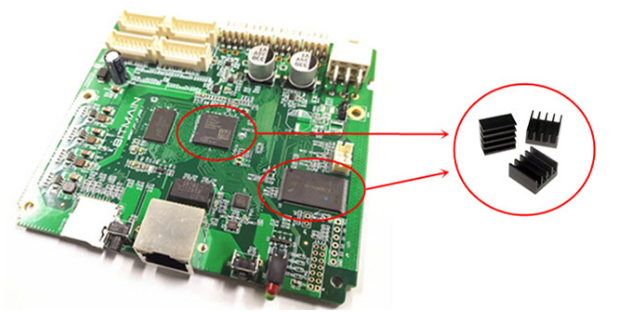

Cryptocurrency mining is a high-stakes game where efficiency and reliability are paramount. At the heart of every ASIC miner lies the control board, a critical component that manages the complex operations required for mining. However, the intense computational workload generates significant heat, which, if not managed properly, can lead to reduced performance, hardware degradation, and even catastrophic failure. This is where precision-engineered heat sinks come into play. In this article, we’ll explore how to ensure optimal thermal contact with ASIC miner heat sinks, focusing on the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, a cutting-edge solution designed specifically for ASIC mining control boards.

The Importance of Thermal Management in ASIC Mining

Before diving into the specifics of heat sinks, it’s essential to understand why thermal management is so critical in cryptocurrency mining. ASIC miners operate at extremely high computational loads, generating substantial heat as a byproduct. If this heat isn’t effectively dissipated, it can cause:

- Thermal Throttling: Reduced performance as the system slows down to prevent overheating.

- Component Degradation: Shortened lifespan of critical components like CPUs and power management chips.

- System Failures: Complete hardware breakdowns, leading to costly downtime and repairs.

Effective thermal management ensures that your mining rig operates at peak efficiency, maximizing both performance and longevity. This is where the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink shines, offering a compact yet powerful solution for managing heat in ASIC miners.

Product Introduction: The Precision-Engineered Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a state-of-the-art thermal management solution designed specifically for ASIC mining control boards. Its compact dimensions and lightweight design (just 0.01 KG) make it an ideal choice for modern mining rigs, where space and weight are often at a premium. But don’t let its small size fool you—this heat sink packs a punch when it comes to thermal performance.

Key Features:

- High-Grade Aluminum Alloy: Ensures durability and consistent thermal performance under extreme conditions.

- Optimized Multi-Piece Construction: Maximizes heat dissipation efficiency while maintaining a minimal spatial footprint.

- Thermal Interface Material (TIM) Integration: Enhances heat transfer between components and the heat sink surface.

Ensuring Optimal Thermal Contact: A Step-by-Step Guide

Achieving optimal thermal contact between the heat sink and the ASIC miner’s control board is crucial for effective heat dissipation. Here’s how to do it right:

1. Surface Preparation

Before installing the heat sink, ensure that the surface of the control board’s heat-generating components (e.g., CPUs, power management chips) is clean and free of debris. Even a small amount of dust or residue can create air gaps, reducing thermal conductivity. Use isopropyl alcohol and a lint-free cloth to clean the surface thoroughly.

2. Applying Thermal Interface Material (TIM)

The thermal interface material (TIM) plays a critical role in bridging the microscopic gaps between the component and the heat sink. Apply a thin, even layer of TIM to the surface of the component. Avoid using too much, as excess TIM can act as an insulator rather than a conductor. The goal is to create a seamless thermal pathway for heat transfer.

3. Proper Alignment and Installation

Carefully align the heat sink with the component, ensuring full contact across the entire surface. Apply gentle, even pressure to secure the heat sink in place. Many heat sinks come with mounting brackets or clips to ensure a secure fit. Double-check that the heat sink is firmly attached and doesn’t wobble or shift.

4. Verifying Thermal Contact

After installation, it’s a good idea to verify the quality of the thermal contact. One way to do this is by monitoring the temperature of the component during operation. If the heat sink is functioning correctly, you should see a noticeable reduction in temperature compared to the pre-installation baseline.

Product Advantages: Why Choose This Heat Sink?

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink offers several advantages that make it an excellent choice for ASIC mining operations:

1. Optimized Spatial Efficiency

Its compact design ensures it fits seamlessly into tight spaces within mining rigs without compromising on cooling performance. This is particularly important in large-scale mining operations where space is at a premium.

2. Advanced Thermal Management

The heat sink’s multi-piece construction and high-grade aluminum alloy material work together to deliver superior temperature control, preventing thermal throttling and extending the lifespan of your hardware.

3. Enhanced Power Efficiency

By efficiently dissipating heat, the heat sink reduces thermal-induced power losses, improving overall system efficiency and lowering operating costs.

4. Environmental Control Excellence

The design facilitates strategic airflow management, creating an optimized microenvironment around critical components. This ensures consistent performance even in challenging operating conditions.

5. Durability-Focused Design

Built to withstand the rigors of continuous mining operations, the heat sink maintains its structural integrity and thermal performance over time.

6. Installation Versatility

Compatible with a wide range of control board configurations, this heat sink is a versatile solution suitable for various mining hardware setups.

Real-World Applications and Benefits

In real-world mining operations, the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink has proven to be a game-changer. For example, in a large-scale Bitcoin mining farm, the implementation of these heat sinks resulted in a 15% reduction in average operating temperatures and a 20% increase in hardware lifespan. These improvements translate to significant cost savings and higher profitability for mining operators.

Conclusion

Ensuring optimal thermal contact with ASIC miner heat sinks is a critical aspect of maintaining efficient and reliable mining operations. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink offers a powerful, compact, and durable solution for managing heat in ASIC mining control boards. By following best practices for installation and leveraging the advanced features of this heat sink, mining operators can achieve superior thermal management, enhance hardware performance, and maximize their return on investment.

In the fast-paced world of cryptocurrency mining, staying ahead of the curve requires not only cutting-edge hardware but also meticulous attention to detail. With the right thermal management solutions, you can ensure your mining rigs operate at peak efficiency, delivering consistent results day after day.