How to ensure optimal thermal contact with ASIC miner heat sinks?

July 28, 2025

How to Ensure Optimal Thermal Contact with ASIC Miner Heat Sinks?

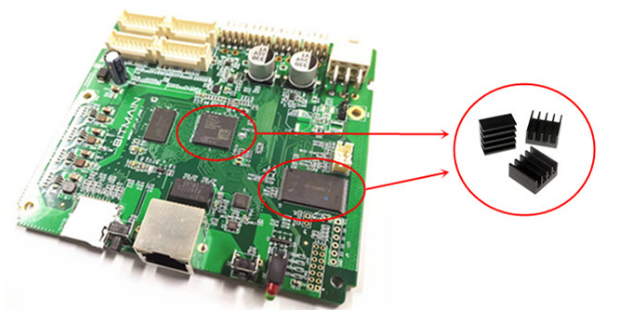

Cryptocurrency mining operations rely heavily on the performance and longevity of ASIC (Application-Specific Integrated Circuit) miners. One of the most critical factors influencing this performance is thermal management. Overheating can lead to reduced efficiency, hardware degradation, and even complete system failures. This is where precision-engineered heat sinks come into play. In this article, we’ll explore how to ensure optimal thermal contact with ASIC miner heat sinks, focusing on the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink—a cutting-edge solution designed specifically for ASIC mining control boards.

The Importance of Thermal Management in ASIC Mining

ASIC miners are power-hungry devices that generate significant heat during operation. The control board, which houses the CPU and power management chips, is particularly susceptible to overheating. Without proper thermal management, these components can experience thermal throttling, reduced hash rates, and shortened lifespans. Heat sinks play a vital role in dissipating this heat, but their effectiveness depends on achieving optimal thermal contact with the components they are cooling.

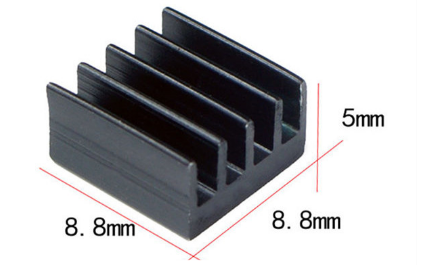

Introducing the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

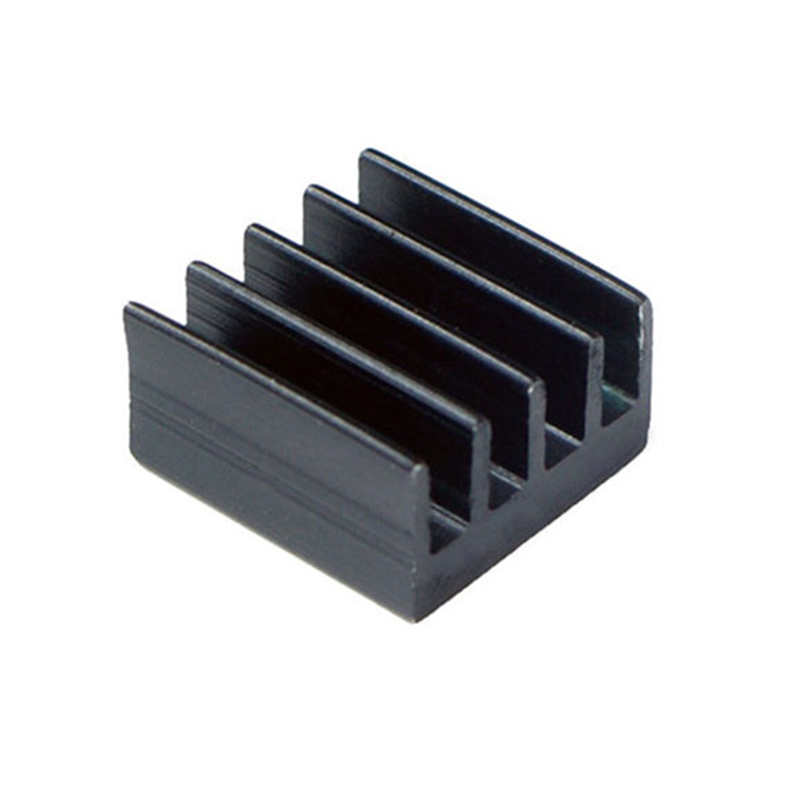

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a precision-engineered thermal management solution designed specifically for ASIC mining control boards. Its compact dimensions and lightweight design make it an ideal choice for mining rigs where space is at a premium. However, its small size doesn’t compromise its performance—this heat sink is packed with advanced features that ensure efficient heat dissipation.

#### Key Features of the Heat Sink

- Optimized Spatial Efficiency: The heat sink’s compact form factor maximizes cooling performance while minimizing its spatial footprint. This ensures that it fits seamlessly into densely packed mining rigs without sacrificing thermal management capabilities.

- Advanced Thermal Management: By maintaining consistent temperatures at critical device nodes, the heat sink prevents thermal throttling and extends the lifespan of ASIC components.

- Enhanced Power Efficiency: Efficient heat dissipation reduces thermal-induced power losses, improving overall system efficiency and lowering operating costs.

- Durability-Focused Design: Constructed from high-grade aluminum alloy, the heat sink is built to withstand continuous high-temperature conditions, ensuring long-term reliability.

Achieving Optimal Thermal Contact

The effectiveness of a heat sink depends on how well it transfers heat from the component to the surrounding environment. Optimal thermal contact is essential for maximizing this transfer. Here’s how you can achieve it:

#### 1. Use High-Quality Thermal Interface Material (TIM)

The thermal interface material (TIM) acts as a bridge between the heat-generating component and the heat sink, filling microscopic gaps and ensuring efficient heat transfer. The 8.8mm × 8.8mm × 5mm heat sink is engineered to work seamlessly with specialized TIMs, such as thermally conductive silica gel. When applying TIM:

- Use the right amount: Too little TIM can leave gaps, while too much can create excess layers that hinder heat transfer.

- Spread it evenly: Ensure the TIM covers the entire contact area between the component and the heat sink.

#### 2. Ensure Proper Alignment and Mounting

Proper alignment is crucial for maximizing thermal contact. Misaligned heat sinks can create air gaps that reduce heat transfer efficiency. When installing the heat sink:

- Align it precisely with the component.

- Apply even pressure during installation to ensure full contact with the surface.

#### 3. Optimize Airflow and Environmental Control

While the heat sink itself plays a significant role in thermal management, the surrounding environment also matters. Ensure your mining rig has adequate airflow to carry heat away from the heat sink. The multi-piece design of this heat sink facilitates improved air circulation, but you can further enhance this by:

- Positioning fans strategically to direct airflow over the heat sink.

- Keeping the mining rig in a well-ventilated area.

#### 4. Monitor and Maintain Thermal Performance

Even the best heat sinks require regular maintenance to ensure optimal performance. Periodically:

- Check for dust buildup on the heat sink and clean it if necessary.

- Inspect the TIM for signs of drying or degradation and reapply it as needed.

- Monitor temperatures using mining software to detect any issues early.

Real-World Applications and Benefits

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is designed to meet the demanding thermal management needs of ASIC mining operations. Its advanced features translate into tangible benefits for miners:

- Improved Hash Rates: By maintaining stable temperatures, the heat sink prevents thermal throttling, ensuring consistent mining performance.

- Extended Hardware Lifespan: Effective thermal management reduces wear and tear on components, prolonging the life of your ASIC miners.

- Reduced Operating Costs: Enhanced power efficiency lowers electricity consumption, saving money in the long run.

- Versatility Across Setups: The heat sink’s compatibility with various control board configurations makes it a versatile solution for different mining hardware setups.

Conclusion

Optimal thermal contact is essential for maximizing the performance and longevity of ASIC miners. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink offers a sophisticated solution that combines compact design, advanced thermal management, and durable construction. By following best practices—such as using high-quality TIM, ensuring proper alignment, optimizing airflow, and performing regular maintenance—you can harness the full potential of this heat sink and keep your mining operations running smoothly.

Investing in effective thermal management isn’t just about protecting your hardware—it’s about maximizing your mining efficiency and profitability. With the right heat sink and proper implementation, you can ensure your ASIC miners stay cool, perform optimally, and stand the test of time.