How to install heat sinks for effective temperature control in ASIC miners?-ASIC miner control board/chip’s heat sinks

December 27, 2024

Here’s a comprehensive article on heat sink installation for ASIC miners:

Title: Mastering ASIC Miner Thermal Management: A Comprehensive Guide to Heat Sink Installation and Performance Optimization

Introduction:

In the high-stakes world of cryptocurrency mining, temperature control isn’t just a technical consideration—it’s a critical factor that can make or break your mining operation’s profitability and longevity. Heat management represents the thin line between consistent performance and catastrophic hardware failure. This guide will dive deep into the intricate process of heat sink installation, providing miners with a comprehensive strategy to optimize thermal performance in ASIC mining environments.

Understanding Thermal Dynamics in ASIC Mining

Cryptocurrency mining pushes hardware components to their absolute limits. The continuous computational processes generate substantial heat, creating a challenging thermal environment that demands precise management. ASIC (Application-Specific Integrated Circuit) miners, designed specifically for cryptocurrency mining, generate intense heat during their operational cycles.

The fundamental challenge lies in dissipating heat efficiently while maintaining optimal performance. A well-implemented heat sink strategy can dramatically improve system stability, extend hardware lifespan, and maximize mining efficiency.

Key Thermal Management Principles

1. Heat Transfer Fundamentals

Heat transfer in mining hardware occurs through three primary mechanisms:

– Conduction: Direct heat transfer through solid materials

– Convection: Heat transfer through fluid movement (air)

– Radiation: Heat transfer through electromagnetic waves

Effective heat sink design must optimize these mechanisms to create a comprehensive cooling solution.

2. Thermal Resistance Considerations

Thermal resistance represents the material’s ability to impede heat flow. Lower thermal resistance means more efficient heat transfer, which is crucial in ASIC mining environments.

Strategic Heat Sink Selection and Installation

Selecting the Right Heat Sink

When choosing a heat sink for ASIC mining control boards, consider these critical factors:

a) Material Composition

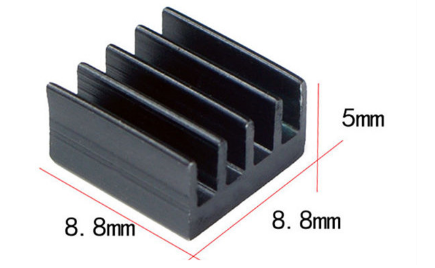

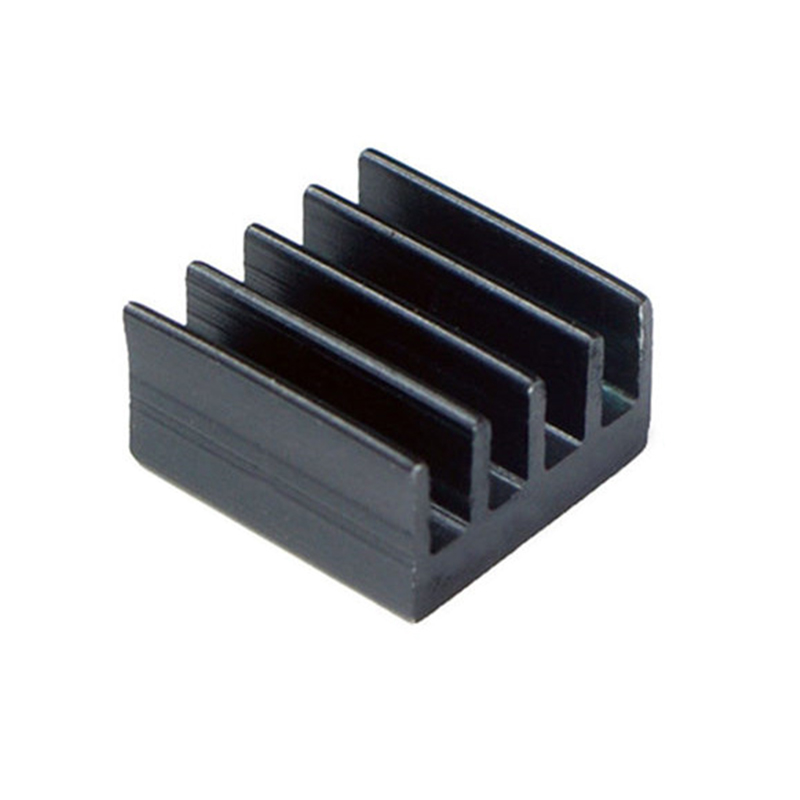

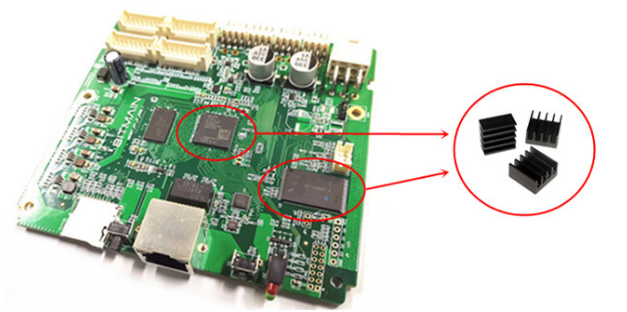

Aluminum alloy heat sinks, like the 8.8mm × 8.8mm × 5mm precision-engineered solution, offer an optimal balance between thermal conductivity and weight. The material’s inherent properties facilitate rapid heat dissipation while maintaining a lightweight profile.

b) Dimensional Optimization

Compact heat sinks with strategic geometric designs maximize cooling performance within limited spatial constraints. The recommended 8.8mm × 8.8mm × 5mm form factor ensures efficient thermal management without compromising valuable mining rig real estate.

Preparation for Heat Sink Installation

Essential Tools and Materials:

– Thermal interface material (TIM)

– Precision screwdriver set

– Thermal grease/paste

– Isopropyl alcohol

– Lint-free cleaning cloth

– Anti-static wrist strap

Pre-Installation Checklist:

1. Power down and disconnect mining hardware

2. Ground yourself to prevent electrostatic discharge

3. Clean contact surfaces thoroughly

4. Inspect heat sink and mounting surfaces for damage

Detailed Installation Procedure

Step 1: Surface Preparation

– Clean the control board’s component surfaces using isopropyl alcohol

– Remove any existing thermal material

– Ensure surfaces are completely dry and free from contaminants

Step 2: Thermal Interface Material Application

– Apply a thin, uniform layer of thermal interface material

– Use recommended silica gel-based TIM for optimal thermal conductivity

– Avoid excessive material application to prevent thermal insulation

Step 3: Heat Sink Positioning

– Align heat sink precisely with target components

– Ensure complete surface contact

– Apply gentle, even pressure during mounting

Step 4: Securing Mechanism

– Use manufacturer-recommended mounting hardware

– Apply consistent torque to prevent uneven pressure distribution

– Verify secure attachment without component stress

Advanced Thermal Management Techniques

1. Airflow Optimization

– Implement strategic case ventilation

– Use high-performance fans with appropriate CFM ratings

– Create consistent airflow patterns around critical components

2. Temperature Monitoring

– Integrate digital temperature sensors

– Implement automated thermal throttling mechanisms

– Establish real-time monitoring systems

Performance Benefits of Precise Heat Management

– Reduced thermal throttling

– Extended hardware lifespan

– Consistent mining performance

– Lower power consumption

– Minimized risk of catastrophic failure

Common Installation Mistakes to Avoid

1. Inadequate surface preparation

2. Uneven thermal interface material application

3. Excessive mounting pressure

4. Neglecting ongoing maintenance

Maintenance Recommendations

– Periodic thermal interface material reapplication (every 6-12 months)

– Regular dust removal

– Consistent airflow path maintenance

– Annual comprehensive thermal system evaluation

Conclusion: Thermal Excellence in Mining Operations

Effective heat sink installation transcends mere technical procedure—it represents a strategic investment in mining infrastructure. By implementing precise thermal management techniques, miners can unlock consistent performance, extend hardware lifespan, and optimize overall operational efficiency.

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents more than a cooling component; it’s a critical performance optimization tool designed to meet the demanding requirements of modern cryptocurrency mining environments.

Investing time and precision in thermal management delivers tangible returns through improved system reliability and sustained mining productivity.

Recommendations for Further Exploration:

– Consult manufacturer-specific thermal guidelines

– Stay updated on emerging cooling technologies

– Continuously monitor and optimize thermal performance

|

Please feel free to contact me to assist you in resolving your issues: E-mail: Minerfixessales@gmail.com WhatsApp/WeChat:+86 15928044684

The services we offer include:

a.New and Used Miners b.Miner Accessories c.Miner Repair Courses d.Global Repair Stations e.Overclocking and Underclocking Services |

|