How to integrate BM1368 Series ASIC Chip Tester with mining repair tools?

February 19, 2025

How to Integrate BM1368 Series ASIC Chip Tester with Mining Repair Tools?

The cryptocurrency mining industry operates on the backbone of highly specialized hardware, with ASIC (Application-Specific Integrated Circuit) chips being the heart of mining machines. Ensuring these chips are functioning optimally is critical to maintaining the efficiency and profitability of mining operations. The BM1368 Series ASIC Chip Tester emerges as a game-changing diagnostic tool designed specifically for the comprehensive testing and validation of BM1368 series chips. In this article, we’ll explore how to seamlessly integrate this advanced tester with existing mining repair tools, highlighting its practical applications and operational benefits.

Product Introduction: The BM1368 Series ASIC Chip Tester

The BM1368 Series ASIC Chip Tester is a precision diagnostic instrument engineered to meet the rigorous demands of professional mining maintenance teams and repair centers. It supports the entire BM1368 chip family, including variants such as BM1368PB, BM1368AA, BM1368PA, and BM1368PV. This versatility makes it an indispensable tool for both new and pre-owned ASIC chips, ensuring they meet performance standards before deployment.

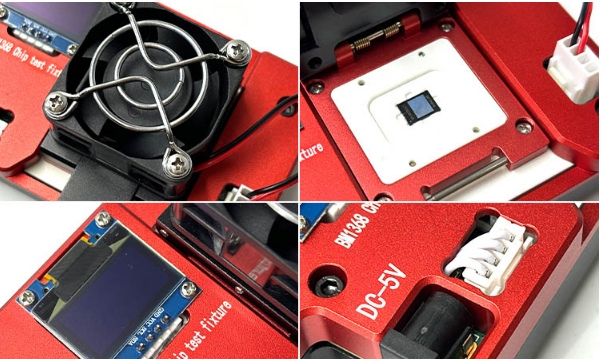

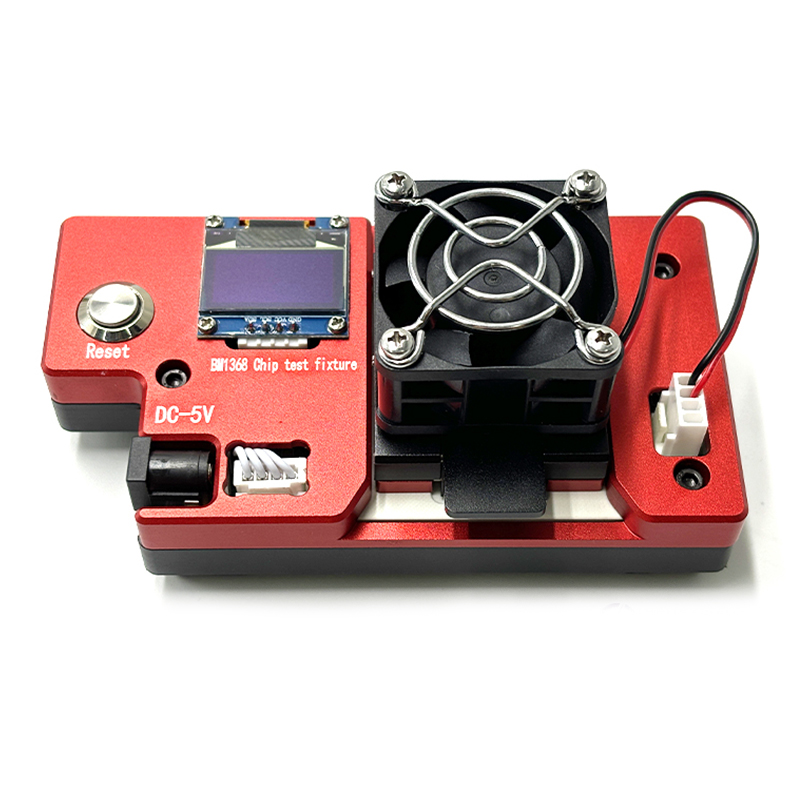

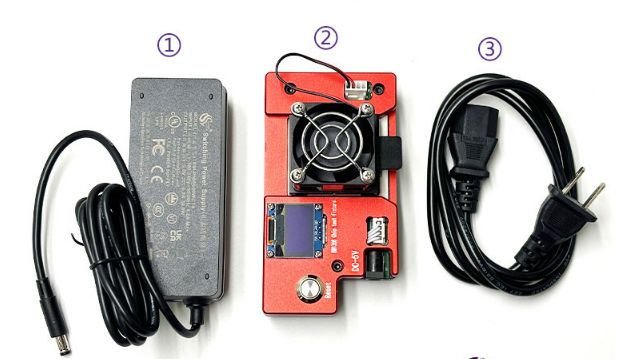

At its core, the tester employs advanced diagnostic algorithms to assess chip functionality and performance metrics quickly and accurately. Its compact, professional-grade design includes a robust test fixture host powered by a dedicated 5V power supply system, ensuring stable testing conditions. With a complete kit that includes a power cable and essential accessories, the BM1368 Series ASIC Chip Tester is ready to integrate into any mining repair workflow.

Key Advantages of the BM1368 Series ASIC Chip Tester

Before diving into integration strategies, it’s essential to understand the unique advantages this tester brings to the table:

- Universal Compatibility: The tester supports all BM1368 series variants, eliminating the need for multiple diagnostic tools and streamlining the testing process.

- Rapid Diagnostic Efficiency: Its advanced algorithms provide instant chip quality assessments, significantly reducing troubleshooting time.

- Quality Assurance Excellence: It validates both new and used ASIC chips, ensuring only high-performing components are deployed in mining rigs.

- Professional Problem Resolution: The tester identifies persistent chip failures that other tools might miss, preventing recurring issues and minimizing downtime.

- Maintenance Optimization: By enabling quick fault detection and quality verification, it enhances the overall efficiency of maintenance workflows.

- ROI-Focused Design: Its compact build and comprehensive capabilities make it a cost-effective solution for mining facilities.

- Enhanced Operational Reliability: It ensures optimal mining performance by verifying chip functionality, reducing the risk of unexpected downtime.

Integrating the BM1368 Series ASIC Chip Tester with Mining Repair Tools

Integrating the BM1368 Series ASIC Chip Tester into your mining repair workflow involves a combination of hardware setup, software configuration, and process optimization. Here’s a step-by-step guide to ensure seamless integration:

1. Setting Up the Hardware

The first step is to prepare the physical setup for the tester. The compact design and lightweight construction (1KG) of the BM1368 Series ASIC Chip Tester make it easy to incorporate into existing repair stations.

- Power Supply: Connect the tester to a stable 5V power source using the included power cable. Ensure the power supply is reliable to avoid fluctuations that could affect testing accuracy.

- Test Fixture Host: Position the test fixture host in a secure, accessible location within your repair station. Its robust design ensures durability even in demanding environments.

- Accessory Organization: Keep the included accessories (e.g., adapters, connectors) organized and within reach for efficient testing.

2. Configuring the Testing Environment

To maximize the tester’s efficiency, configure your workspace to facilitate quick and accurate diagnostics.

- Workflow Integration: Place the tester at a central point in your repair workflow, ideally after initial visual inspections but before final assembly or deployment.

- Ergonomics: Ensure the tester is positioned for easy access, minimizing movement and reducing the time required for each test cycle.

- Safety Measures: Follow standard safety protocols for handling electronic components to prevent damage to the tester or chips.

3. Aligning with Existing Diagnostic Processes

The BM1368 Series ASIC Chip Tester is designed to complement existing diagnostic tools and processes. Here’s how to align it with your current setup:

- Pre-Testing Analysis: Use the tester to validate chips after preliminary diagnostic tools (e.g., multimeters, oscilloscopes) identify potential issues. Its advanced algorithms can confirm or refine initial findings.

- Post-Repair Verification: After repairs are completed, use the tester to ensure the chip is fully functional before reinstalling it in the mining rig.

- Quality Control: Incorporate the tester into your quality control process to verify the performance of new chips before deployment, reducing the risk of defects affecting operations.

4. Leveraging Advanced Features

The BM1368 Series ASIC Chip Tester offers several advanced features that can enhance your repair workflow:

- Instant Diagnosis: Use the tester’s rapid diagnostic capabilities to quickly identify faulty chips, reducing downtime and improving repair turnaround times.

- Persistent Failure Detection: For chips that have undergone multiple repairs, the tester can pinpoint lingering issues that other tools might miss, ensuring comprehensive problem resolution.

- Performance Metrics: Leverage the tester’s detailed performance assessments to optimize chip configurations and maximize mining efficiency.

5. Training Your Team

To fully harness the potential of the BM1368 Series ASIC Chip Tester, ensure your maintenance team is well-trained in its operation.

- Hands-On Training: Provide hands-on training sessions to familiarize technicians with the tester’s features and functionalities.

- Documentation: Use the included documentation to create a quick reference guide for common testing scenarios.

- Troubleshooting: Equip your team with troubleshooting tips for resolving any issues that may arise during testing.

Real-World Applications and Benefits

Integrating the BM1368 Series ASIC Chip Tester into your mining repair workflow offers tangible benefits across various scenarios:

- High-Volume Mining Farms: For large-scale operations, the tester’s rapid diagnostics and universal compatibility ensure minimal downtime and maximum productivity.

- Repair Centers: Professional repair centers can use the tester to validate repairs and provide clients with guaranteed performance assurances.

- Second-Hand Chip Markets: The tester is invaluable for verifying the quality of pre-owned ASIC chips, ensuring they meet operational standards before resale or reuse.

Conclusion

The BM1368 Series ASIC Chip Tester is more than just a diagnostic tool—it’s a comprehensive solution for optimizing cryptocurrency mining operations. By integrating it with your existing repair tools and workflows, you can achieve faster diagnostics, improved quality assurance, and enhanced operational reliability. Its universal compatibility, rapid testing capabilities, and professional-grade design make it an essential investment for mining facilities and repair centers alike.

Whether you’re managing a high-volume mining farm or operating a professional repair service, the BM1368 Series ASIC Chip Tester empowers you to maintain peak performance, minimize downtime, and maximize ROI. Embrace this advanced diagnostic solution and take your mining operations to the next level.