How to integrate heat sinks with ASIC miner chips for maximum cooling?

March 7, 2025

How to Integrate Heat Sinks with ASIC Miner Chips for Maximum Cooling?

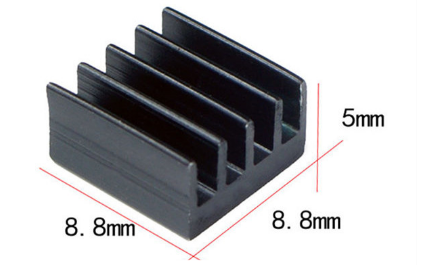

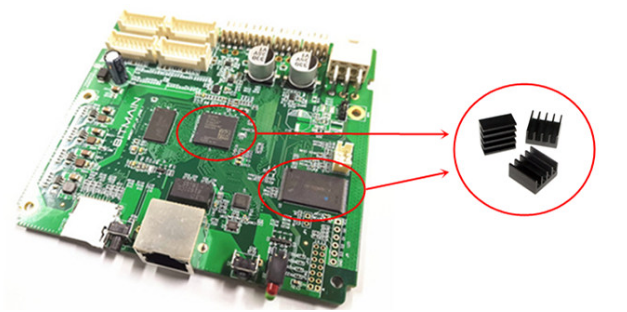

Cryptocurrency mining has evolved into a highly competitive industry where efficiency and reliability are paramount. One of the most critical aspects of maintaining optimal mining performance is effective thermal management. ASIC (Application-Specific Integrated Circuit) miners, the backbone of modern cryptocurrency mining, generate significant heat during operation. Without proper cooling, this heat can lead to thermal throttling, reduced performance, and even hardware failure. This is where precision-engineered heat sinks come into play. In this article, we’ll explore how to integrate heat sinks with ASIC miner chips for maximum cooling, focusing on a specialized 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed for ASIC mining control boards.

The Importance of Thermal Management in Cryptocurrency Mining

ASIC miners are designed to perform repetitive hashing operations at incredible speeds, making them highly efficient but also heat-intensive. High temperatures can degrade the performance and lifespan of mining hardware, leading to increased downtime and maintenance costs. Effective thermal management ensures that the chips operate within their optimal temperature range, preventing thermal throttling and maintaining consistent mining output.

Heat sinks are essential components in this process, as they dissipate heat away from critical components like CPUs and power management chips. However, not all heat sinks are created equal. The integration of a heat sink with an ASIC miner chip requires careful consideration of design, materials, and installation techniques to maximize cooling efficiency.

Product Introduction: The Precision-Engineered Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution specifically designed for ASIC mining control boards. Its compact form factor and advanced engineering make it an ideal choice for cryptocurrency mining operations. Here’s a closer look at its key features:

Technical Architecture

Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction optimized for maximum thermal dissipation. The design incorporates fins and grooves that increase surface area, facilitating rapid heat transfer from the chip to the surrounding environment.

Thermal Interface Integration

The heat sink is paired with a specialized thermal interface material (TIM), such as thermally conductive silica gel, to ensure optimal thermal conductivity between the chip and the heat sink. This layer eliminates air gaps and enhances heat transfer efficiency.

Performance Characteristics

With a lightweight design (0.01 KG) and precise dimensions, this heat sink provides exceptional cooling performance without adding significant mass to the control board assembly. Its compact size makes it suitable for densely packed mining rigs.

Product Advantages: Why This Heat Sink Stands Out

Optimized Spatial Efficiency

The heat sink’s compact dimensions (8.8mm × 8.8mm × 5mm) are carefully calculated to maximize cooling performance while minimizing its spatial footprint. This is particularly important in mining rigs, where space is often at a premium.

Advanced Thermal Management

By maintaining consistent temperatures at critical device nodes, this heat sink prevents thermal throttling and extends the lifespan of ASIC miner components. Its efficient heat dissipation ensures that chips operate within their specified thermal limits.

Enhanced Power Efficiency

Efficient thermal management reduces thermal-induced power losses, resulting in improved overall system efficiency. This translates to lower operating costs and higher profitability for mining operators.

Environmental Control Excellence

The multi-piece design facilitates strategic airflow management, creating an optimized microenvironment around critical components. This ensures even heat distribution and minimizes hot spots.

Durability-Focused Design

Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous high-temperature operation. Its robust design ensures long-term reliability and consistent thermal performance.

Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency and ensuring consistent thermal conductivity across the entire contact area.

Installation Versatility

Designed for compatibility with various control board configurations, this heat sink can be easily integrated into different mining hardware setups. Its versatility makes it a valuable addition to any mining operation.

Step-by-Step Guide to Integrating Heat Sinks with ASIC Miner Chips

Proper integration of heat sinks with ASIC miner chips is crucial for maximizing cooling efficiency. Here’s a practical guide to help you get it right:

1. Prepare the Surface

Before installing the heat sink, ensure that the surface of the ASIC miner chip is clean and free of dust or debris. Any contaminants can interfere with thermal conductivity and reduce cooling performance.

2. Apply Thermal Interface Material (TIM)

Apply a thin, even layer of thermal interface material (such as thermally conductive silica gel) to the surface of the chip. This layer acts as a bridge between the chip and the heat sink, enhancing heat transfer efficiency.

3. Position the Heat Sink

Carefully align the heat sink with the chip, ensuring that it sits flush on the surface. Avoid applying excessive pressure, as this can damage the chip or create air gaps in the TIM layer.

4. Secure the Heat Sink

Most heat sinks come with clips or adhesive pads to secure them in place. Follow the manufacturer’s instructions to ensure proper installation. Double-check that the heat sink is firmly attached and making full contact with the chip.

5. Monitor Thermal Performance

After installation, monitor the temperature of the ASIC miner chip to ensure that the heat sink is functioning as intended. Use thermal imaging or onboard temperature sensors to verify that the chip is operating within its optimal temperature range.

Real-World Applications and Benefits

Integrating precision-engineered heat sinks with ASIC miner chips offers numerous benefits for cryptocurrency mining operations:

- Extended Hardware Lifespan: Effective thermal management reduces wear and tear on mining hardware, extending its operational lifespan.

- Consistent Mining Performance: By preventing thermal throttling, heat sinks ensure that ASIC miners operate at peak efficiency, maintaining consistent hash rates.

- Reduced Operating Costs: Efficient cooling minimizes power losses and reduces the need for frequent maintenance, lowering overall operating costs.

- Improved Profitability: Enhanced performance and reduced downtime translate to higher profitability for mining operators.

Conclusion

Thermal management is a critical factor in the success of any cryptocurrency mining operation. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents a state-of-the-art solution for cooling ASIC miner chips, offering optimized spatial efficiency, advanced thermal management, and enhanced power efficiency. By following the step-by-step integration guide outlined in this article, mining operators can maximize cooling performance and ensure the longevity and reliability of their hardware.

Investing in high-quality heat sinks is not just about protecting your equipment—it’s about optimizing your mining operation for sustained success in the competitive world of cryptocurrency mining. Whether you’re a seasoned miner or just starting out, integrating precision-engineered heat sinks into your setup is a smart move that pays dividends in the long run.