How to maintain Iceriver KS5L/KS5M water cooling plate kit for continuous operation?

July 25, 2025

How to Maintain Iceriver KS5L/KS5M Water Cooling Plate Kit for Continuous Operation?

In the high-stakes world of cryptocurrency mining, maintaining optimal operating conditions for your hardware is critical to maximizing efficiency and ensuring long-term profitability. The Iceriver KS5L/KS5M water cooling plate kit is a cutting-edge solution designed to address the thermal management challenges of Bitmain KS5L and KS5M miners. However, even the most advanced equipment requires proper maintenance to deliver consistent performance. This article delves into practical strategies for maintaining your Iceriver water cooling plate kit, ensuring it operates flawlessly under the demanding conditions of continuous mining.

Understanding the Iceriver KS5L/KS5M Water Cooling Plate Kit

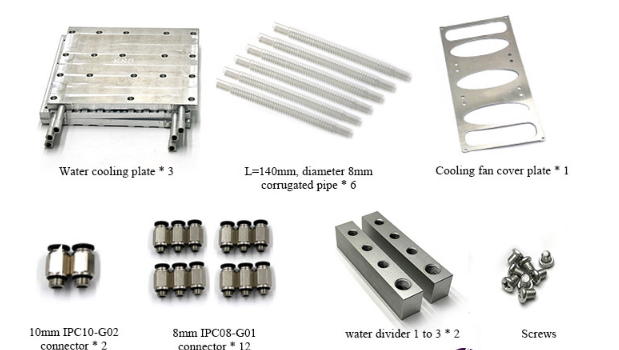

Before diving into maintenance tips, it’s essential to understand the key features and components of the Iceriver KS5L/KS5M water cooling plate kit. This system is engineered to provide superior thermal management for high-performance ASIC miners, combining precision engineering with industrial-grade durability.

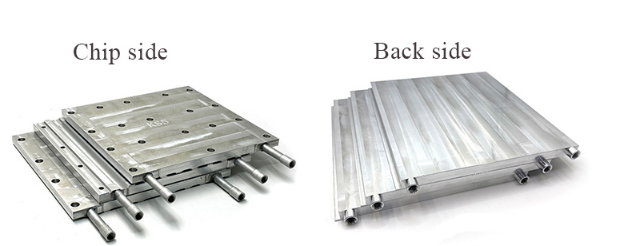

At its core, the kit features triple integrated aluminum water-cooling plates, which are strategically positioned to maximize heat dissipation from the hash boards. The aluminum construction ensures excellent thermal conductivity while resisting corrosion, a critical feature for long-term use in mining environments. The system also includes a dual water separator design that optimizes coolant distribution and flow dynamics, ensuring uniform cooling across all components.

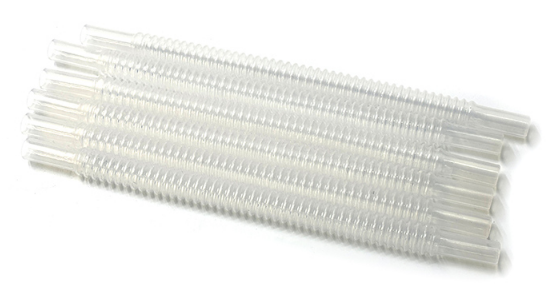

One of the standout features of this kit is its quick-connect system, which includes 26 precision-engineered connectors. These connectors not only simplify installation and maintenance but also guarantee zero-leak operation, a vital consideration for any water cooling system. Additionally, the twelve corrugated bellows accommodate thermal expansion and contraction, maintaining system integrity during continuous operation.

Finally, the specialized cover plate provides comprehensive protection against environmental contaminants, safeguarding the internal components and ensuring reliable performance. Together, these features make the Iceriver KS5L/KS5M water cooling plate kit a robust and efficient solution for managing the heat generated by high-performance mining rigs.

Why Maintenance Matters

While the Iceriver KS5L/KS5M water cooling plate kit is designed for durability and reliability, regular maintenance is essential to prevent issues that could compromise its performance. Over time, dust, debris, and mineral deposits can accumulate within the system, potentially leading to reduced cooling efficiency, blockages, or even hardware damage. Proper maintenance not only extends the lifespan of the cooling system but also ensures that your miners operate at peak efficiency, minimizing downtime and maximizing profitability.

Step-by-Step Maintenance Guide

#### 1. Regular Inspection and Cleaning

The first step in maintaining your Iceriver water cooling plate kit is to conduct regular inspections. Check the system for any visible signs of wear, corrosion, or leaks. Pay close attention to the quick-connect connectors and corrugated bellows, as these are critical components for maintaining airtightness and smooth coolant flow.

To clean the system, start by gently removing any dust or debris from the exterior surfaces using a soft brush or compressed air. Avoid using harsh chemicals or abrasive materials, as these could damage the aluminum plates or other components. If you notice any buildup inside the cooling plates or water separators, flush the system with distilled water to remove contaminants.

#### 2. Monitor Coolant Quality

The quality of the coolant used in your water cooling system plays a significant role in its performance and longevity. Over time, coolant can degrade due to exposure to heat and contaminants, reducing its effectiveness. To maintain optimal cooling efficiency, regularly check the coolant level and quality.

If you notice discoloration or particulate matter in the coolant, it’s time to replace it. Always use a high-quality, corrosion-inhibited coolant specifically designed for water cooling systems. When replacing the coolant, flush the system thoroughly to remove any residue before refilling it with fresh coolant.

#### 3. Inspect and Tighten Connectors

The quick-connect system is one of the most critical components of the Iceriver KS5L/KS5M water cooling plate kit. Over time, vibrations and thermal cycling can cause connectors to loosen, potentially leading to leaks. During routine maintenance, inspect each of the 26 connectors for signs of wear or loosening.

If any connectors appear damaged, replace them immediately to prevent leaks. Tighten any loose connectors using the appropriate tools, but avoid over-tightening, as this could damage the threads or seals. Regularly checking and maintaining the connectors will ensure the system remains leak-free and operates efficiently.

#### 4. Address Thermal Expansion and Contraction

The twelve corrugated bellows in the Iceriver cooling system are designed to accommodate thermal expansion and contraction, which occur as the temperature of the system fluctuates during operation. However, it’s essential to ensure that these bellows remain flexible and free from obstructions.

During maintenance, inspect the bellows for any signs of stiffness, cracking, or deformation. If you notice any issues, replace the affected bellows to maintain the system’s integrity. Additionally, ensure that the bellows are properly aligned and not subjected to excessive stress, which could compromise their functionality.

#### 5. Protect Against Environmental Contaminants

The specialized cover plate of the Iceriver KS5L/KS5M water cooling plate kit is designed to protect the internal components from dust, dirt, and other environmental contaminants. However, it’s still important to take additional steps to safeguard the system.

Ensure that your mining facility is kept clean and free from excessive dust. Use air filters or dust covers to minimize the amount of particulate matter that enters the cooling system. Regularly inspect the cover plate for any signs of damage or wear, and replace it if necessary.

#### 6. Optimize Coolant Flow Dynamics

The dual water separator configuration is engineered to optimize coolant circulation and ensure uniform cooling across all hash boards. To maintain optimal flow dynamics, periodically check the water separators for any blockages or restrictions.

If you notice a decrease in cooling efficiency, it could indicate a problem with the water separators. Flush the system to remove any debris or buildup that may be affecting coolant flow. Additionally, ensure that the water pipes are properly aligned and free from kinks or bends that could restrict flow.

Best Practices for Continuous Operation

In addition to regular maintenance, there are several best practices you can follow to ensure the continuous operation of your Iceriver KS5L/KS5M water cooling plate kit:

- Maintain Stable Ambient Temperatures: Keep the mining environment at a stable temperature to reduce the strain on the cooling system. Excessive heat can lead to increased thermal cycling, which may accelerate wear and tear.

- Monitor System Performance: Use monitoring software to track the temperature and performance of your miners. This will allow you to identify any potential issues before they escalate into major problems.

- Schedule Preventative Maintenance: Establish a regular maintenance schedule to keep the cooling system in optimal condition. Preventative maintenance is far more cost-effective than dealing with unexpected failures or downtime.

- Train Your Team: Ensure that your team is familiar with the operation and maintenance of the Iceriver KS5L/KS5M water cooling plate kit. Well-trained operators are better equipped to identify and address potential issues.

Conclusion

The Iceriver KS5L/KS5M water cooling plate kit is a powerful tool for managing the thermal demands of high-performance ASIC miners. By following the maintenance guidelines outlined in this article, you can ensure that your cooling system operates efficiently and reliably, even under the most challenging conditions. Regular inspections, proper coolant management, and attention to detail will go a long way in extending the lifespan of your equipment and maximizing your mining profitability.

Remember, proactive maintenance is the key to uninterrupted operation. By investing time and effort into caring for your Iceriver water cooling plate kit, you’ll be well-positioned to reap the rewards of a high-performing, efficient mining operation.