How to maintain optimal temperature in ASIC mining rigs with heat sinks?

August 3, 2025

How to Maintain Optimal Temperature in ASIC Mining Rigs with Heat Sinks?

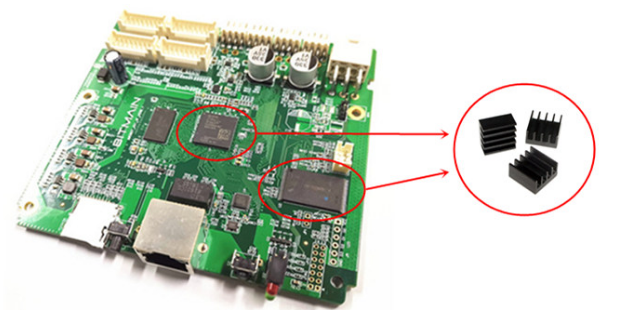

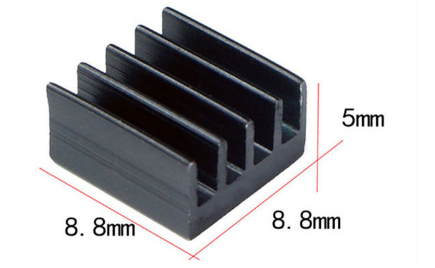

Cryptocurrency mining has evolved into a highly competitive and technically demanding industry, where even minor inefficiencies can significantly impact profitability. Among the most critical factors influencing mining performance is temperature control. Overheating can lead to reduced efficiency, hardware degradation, and even complete failure of mining equipment. For ASIC (Application-Specific Integrated Circuit) miners, effective thermal management is not just a luxury—it’s a necessity. This article delves into the role of heat sinks in maintaining optimal temperatures for ASIC mining rigs, focusing on the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed specifically for ASIC miner control boards.

The Importance of Temperature Control in ASIC Mining

ASIC miners are built to perform complex calculations at lightning speed, generating significant heat in the process. Without proper cooling, this heat can accumulate, leading to thermal throttling—a mechanism where the device reduces its performance to prevent overheating. Thermal throttling directly impacts hash rates, reducing mining efficiency and profitability. Worse still, prolonged exposure to high temperatures can cause permanent damage to sensitive components, shortening the lifespan of expensive mining hardware.

To combat these challenges, miners must implement robust thermal management solutions. While fans and liquid cooling systems play a role, heat sinks are often the first line of defense, providing localized cooling to critical components like CPUs and power management chips on ASIC control boards.

Introducing the Precision-Engineered Aluminum Alloy Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution designed specifically for ASIC mining applications. Its compact, lightweight design makes it ideal for integration into space-constrained mining rigs, while its advanced engineering ensures superior heat dissipation. Let’s explore the key features and advantages of this heat sink in detail.

Optimized Spatial Efficiency

Mining rigs are often densely packed with hardware, leaving little room for additional components. The 8.8mm × 8.8mm × 5mm heat sink is engineered to maximize cooling performance without occupying excessive space. Its precise dimensions allow it to fit seamlessly onto ASIC control boards, ensuring efficient use of available real estate. This spatial efficiency is particularly valuable in large-scale mining operations, where every square inch counts.

Advanced Thermal Management

At the heart of this heat sink’s design is its ability to maintain consistent temperatures at critical device nodes. By rapidly transferring heat away from components, it prevents thermal buildup and keeps operating conditions within safe limits. This precise thermal regulation minimizes the risk of thermal throttling, ensuring that your ASIC miner operates at peak performance.

Enhanced Power Efficiency

Heat is a byproduct of energy consumption, and excessive heat often indicates energy wastage. The aluminum alloy heat sink significantly reduces thermal-induced power losses by efficiently dissipating heat. This not only improves the overall efficiency of the mining rig but also lowers operating costs over time. In an industry where margins are tight, even small improvements in power efficiency can translate into substantial savings.

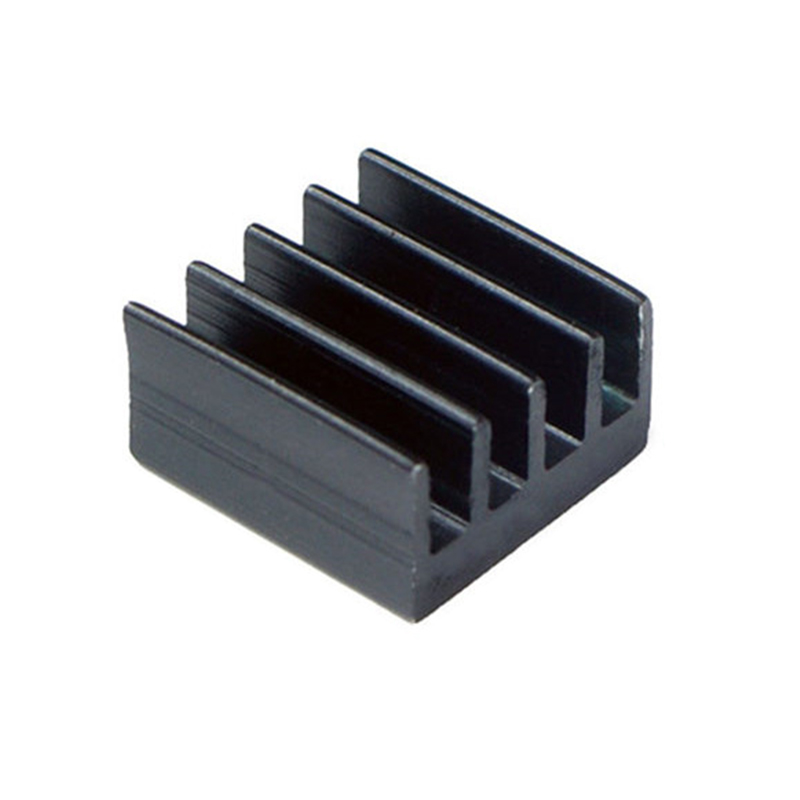

Environmental Control Excellence

The heat sink’s multi-piece design facilitates strategic airflow management, creating an optimized microenvironment around critical components. By improving air circulation and heat displacement, it helps maintain a stable operating environment within the mining rig. This is especially important in large mining farms, where multiple rigs operate in close proximity, generating significant ambient heat.

Durability-Focused Design

Mining operations are relentless, often running 24/7 for extended periods. The aluminum alloy heat sink is built to withstand these demanding conditions. Its premium construction ensures long-term reliability, maintaining consistent thermal performance even under continuous high-temperature stress. This durability reduces the need for frequent maintenance or replacement, further enhancing operational efficiency.

Thermal Interface Optimization

To maximize heat transfer efficiency, the heat sink is designed to work seamlessly with thermal interface materials (TIMs). A specialized thermally conductive silica gel layer ensures optimal contact between the heat-generating components and the heat sink surface. This optimization creates an efficient thermal pathway, allowing heat to dissipate quickly and evenly.

Installation Versatility

Compatibility is key when integrating thermal solutions into existing mining setups. The 8.8mm × 8.8mm × 5mm heat sink is designed to work with various control board configurations, ensuring optimal thermal contact across different hardware setups. This versatility makes it a practical choice for both small-scale miners and large-scale operations.

Practical Applications: How Heat Sinks Enhance Mining Operations

To understand the real-world impact of this heat sink, let’s consider a scenario in a typical ASIC mining farm. Each rig houses multiple ASIC miners, each generating significant heat during operation. Without adequate cooling, the ambient temperature within the farm can rise rapidly, increasing the risk of overheating and hardware failure.

By installing the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink on each control board, miners can achieve several operational benefits:

- Consistent Performance: Maintaining optimal temperatures prevents thermal throttling, ensuring that ASIC miners operate at their maximum hash rate.

- Extended Hardware Lifespan: Effective heat dissipation reduces wear and tear on components, prolonging the life of valuable mining