How to manage airflow for better heat dissipation in ASIC miners?

May 22, 2025

How to Manage Airflow for Better Heat Dissipation in ASIC Miners?

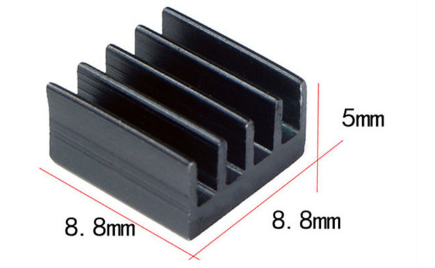

Cryptocurrency mining is a high-stakes game where efficiency and performance are paramount. One of the most critical factors influencing the success of mining operations is thermal management. ASIC miners, the workhorses of cryptocurrency mining, generate significant heat during operation. Without proper heat dissipation, these machines can overheat, leading to reduced performance, increased power consumption, and even hardware failure. This article explores how to manage airflow effectively for better heat dissipation in ASIC miners, with a focus on the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink—a game-changing solution for thermal management in mining control boards.

The Importance of Heat Dissipation in ASIC Mining

ASIC (Application-Specific Integrated Circuit) miners are designed to perform complex calculations at incredible speeds, making them highly efficient for cryptocurrency mining. However, this efficiency comes at a cost: heat. The control board and chips within ASIC miners generate substantial thermal energy, which, if not managed properly, can lead to:

- Thermal Throttling: When components overheat, they reduce their performance to prevent damage, directly impacting mining efficiency.

- Increased Power Consumption: Overheating components require more energy to operate, driving up electricity costs.

- Hardware Degradation: Prolonged exposure to high temperatures can shorten the lifespan of critical components, leading to costly replacements.

Effective heat dissipation is, therefore, essential to maintaining optimal mining operations. This is where advanced thermal management solutions, such as the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, come into play.

Introducing the Precision-Engineered Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution specifically designed for ASIC mining control boards. Its compact yet highly efficient design addresses the unique challenges of cryptocurrency mining, ensuring that critical components remain within safe operating temperatures.

Key Features of the Heat Sink

- Optimized Spatial Efficiency

The heat sink’s compact dimensions (8.8mm × 8.8mm × 5mm) make it ideal for use in densely packed mining rigs. Despite its small size, it delivers exceptional cooling performance without occupying excessive space.

- Advanced Thermal Management

Crafted from high-grade aluminum alloy, the heat sink features a multi-piece construction that maximizes heat dissipation. Its design ensures rapid heat transfer from CPUs and power management chips, preventing thermal throttling and extending component lifespan.

- Enhanced Power Efficiency

By reducing thermal-induced power losses, the heat sink improves overall system efficiency. This translates to lower operating costs and more consistent power delivery to mining components.

- Environmental Control Excellence

The heat sink’s design facilitates strategic airflow management, creating an optimized microenvironment around critical components. This ensures efficient heat distribution and improved air circulation.

- Durability-Focused Design

Made from premium aluminum alloy, the heat sink is built to withstand the rigors of continuous mining operations. It maintains structural integrity even under high-temperature conditions, ensuring long-term reliability.

- Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials (TIM), such as thermally conductive silica gel. This maximizes heat transfer efficiency from components to the heat sink surface.

- Installation Versatility

Designed for compatibility with various control board configurations, the heat sink ensures optimal thermal contact across different mining hardware setups.

Practical Applications: Managing Airflow for Better Heat Dissipation

While the heat sink itself is a critical component, its effectiveness depends on proper airflow management within the mining rig. Here are some practical strategies to optimize airflow and enhance heat dissipation:

1. Strategic Placement of Heat Sinks

Position heat sinks directly over the hottest components, such as CPUs and power management chips. Ensure that the thermal interface material is applied correctly to maximize heat transfer.

2. Optimize Fan Configuration

Use high-quality fans to create a consistent airflow through the mining rig. Position intake fans to draw in cool air and exhaust fans to expel hot air. Ensure that fans are sized appropriately for the rig’s thermal load.

3. Maintain Proper Spacing Between Components

Avoid overcrowding components within the mining rig. Adequate spacing allows for better airflow and prevents heat buildup in specific areas.

4. Use Ducting to Direct Airflow

Install ducting or air channels to guide airflow directly over heat sinks and other critical components. This ensures that cool air reaches the areas that need it most.

5. Monitor and Adjust Airflow Regularly

Use temperature sensors to monitor the thermal performance of your mining rig. Adjust fan speeds and airflow patterns as needed to maintain optimal temperatures.

6. Incorporate External Cooling Solutions

In high-density mining setups, consider using external cooling solutions, such as air conditioning or liquid cooling systems, to supplement internal airflow management.

Real-World Benefits of Effective Airflow Management

Implementing these strategies, along with the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, offers several tangible benefits for mining operators:

- Improved Mining Efficiency: Consistent temperature control prevents thermal throttling, ensuring that ASIC miners operate at peak performance.

- Reduced Operating Costs: Efficient heat dissipation lowers power consumption, reducing electricity bills.

- Extended Hardware Lifespan: By preventing overheating, you can significantly extend the lifespan of your mining equipment, minimizing replacement costs.

- Enhanced Reliability: Proper airflow management reduces the risk of hardware failure, ensuring uninterrupted mining operations.

Conclusion

Managing airflow for better heat dissipation is a critical aspect of successful cryptocurrency mining. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is an indispensable tool in this endeavor, offering advanced thermal management capabilities in a compact, durable package. By combining this innovative heat sink with effective airflow strategies, mining operators can optimize their rigs for maximum efficiency, reliability, and profitability. Whether you’re running a small-scale operation or a large mining farm, investing in proper thermal management is a decision that will pay dividends in the long run.