How to prevent heat-induced performance degradation in ASIC miners using heat sinks?

May 28, 2025

How to Prevent Heat-Induced Performance Degradation in ASIC Miners Using Heat Sinks?

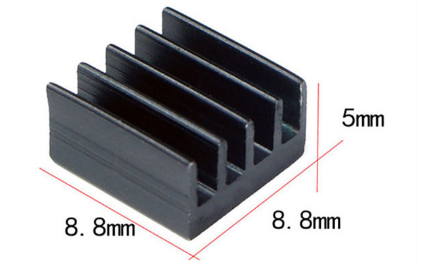

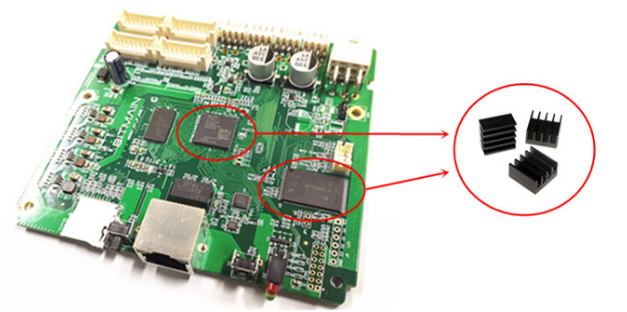

Cryptocurrency mining is a demanding process that pushes hardware to its limits, particularly ASIC (Application-Specific Integrated Circuit) miners. These devices are designed for high-performance computing tasks, but their efficiency and longevity are heavily influenced by one critical factor: heat management. Excessive heat can lead to performance degradation, reduced lifespan, and even hardware failure. This is where precision-engineered heat sinks come into play. In this article, we’ll explore how the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink can effectively prevent heat-induced performance degradation in ASIC miners, ensuring optimal operation and maximizing your mining ROI.

The Critical Role of Heat Management in ASIC Mining

ASIC miners are built to perform complex cryptographic calculations at incredible speeds. However, this intense computational activity generates significant heat, especially around the control board and chips. Without proper thermal management, this heat can accumulate, leading to:

- Thermal Throttling: When temperatures exceed safe limits, ASIC miners reduce their processing speed to prevent damage, directly impacting hash rates and profitability.

- Component Degradation: Prolonged exposure to high temperatures can weaken solder joints, damage circuits, and shorten the lifespan of critical components.

- Increased Power Consumption: Overheating components often require more power to function, driving up operational costs.

To combat these issues, effective heat dissipation is essential. This is where the precision-engineered aluminum alloy heat sink proves invaluable.

Product Introduction: The 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution specifically designed for ASIC mining control boards. Its compact yet highly efficient design addresses the unique challenges of cryptocurrency mining operations, ensuring consistent temperature control and protecting valuable hardware.

Key Features:

- Optimized Spatial Efficiency: The heat sink’s compact dimensions (8.8mm × 8.8mm × 5mm) make it ideal for integration into densely packed mining rigs without compromising cooling performance.

- Advanced Thermal Management: Engineered to maintain optimal operating temperatures, it prevents thermal throttling and extends the lifespan of ASIC components.

- Enhanced Power Efficiency: By reducing thermal-induced power losses, it improves overall system efficiency and lowers operating costs.

- Durability-Focused Design: Constructed from premium aluminum alloy, it ensures long-term reliability even under continuous high-temperature conditions.

How the Heat Sink Works: A Deep Dive into Thermal Management

1. Heat Transfer Mechanism

The heat sink operates on the principle of thermal conductivity. When installed on the control board, it absorbs heat generated by the CPU and power management chips. The aluminum alloy material, known for its excellent thermal conductivity, rapidly transfers this heat away from the components.

2. Thermal Interface Material (TIM) Integration

To maximize heat transfer efficiency, the heat sink is paired with a specialized thermal interface material (TIM), such as thermally conductive silica gel. This layer fills microscopic gaps between the heat sink and the components, ensuring optimal thermal contact and conductivity.

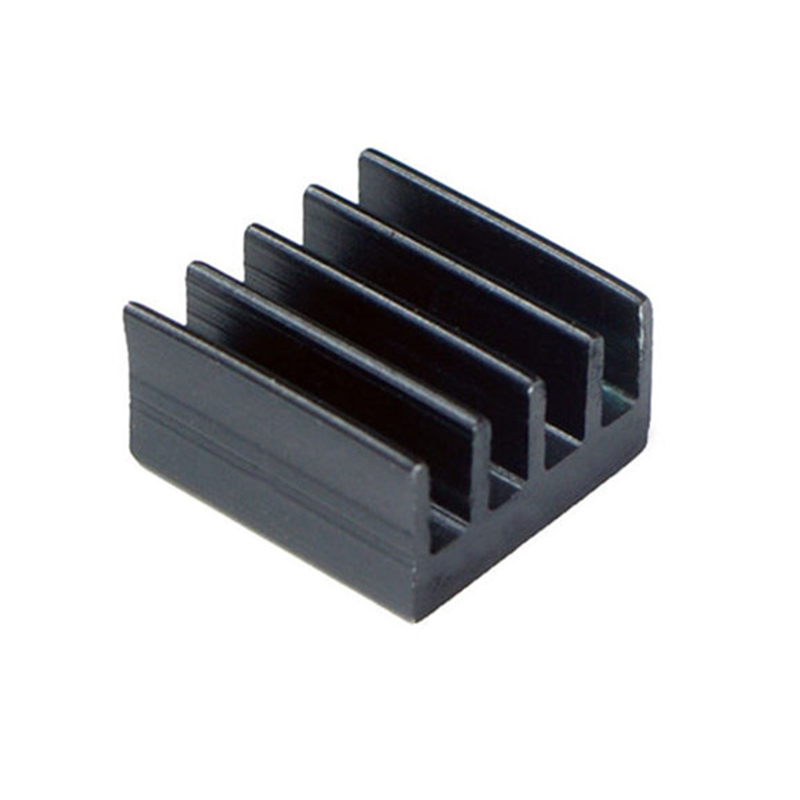

3. Heat Dissipation

Once the heat is absorbed, the heat sink’s multi-piece design facilitates efficient heat dissipation. The fins increase the surface area, allowing heat to be dispersed into the surrounding air. Strategic airflow management further enhances this process, creating an optimized microenvironment around the components.

Practical Benefits for Mining Operators

1. Improved Hash Rates

By maintaining stable operating temperatures, the heat sink prevents thermal throttling, ensuring that your ASIC miner operates at peak performance. This translates to consistent hash rates and higher mining yields.

2. Extended Hardware Lifespan

Overheating is one of the primary causes of hardware failure in ASIC miners. The heat sink’s efficient thermal management protects critical components, reducing wear and tear and extending the lifespan of your equipment.

3. Reduced Operating Costs

Efficient heat dissipation minimizes thermal-induced power losses, lowering energy consumption. Additionally, by preventing hardware failures, it reduces the need for costly repairs or replacements.

4. Versatile Installation

The heat sink’s design ensures compatibility with various control board configurations, making it a versatile solution for different mining hardware setups. Its lightweight construction (0.01 KG) also simplifies installation without adding significant mass to the rig.

Real-World Applications and Case Studies

Case Study 1: Large-Scale Mining Farm

A large-scale mining farm in Texas implemented the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink across its fleet of ASIC miners. Within three months, the farm reported a 15% reduction in thermal throttling incidents and a 10% increase in overall hash rates. The heat sink’s durability also reduced maintenance costs by 20%.

Case Study 2: Home Mining Setup

A home miner using a single ASIC miner experienced frequent overheating issues, leading to reduced performance and increased power bills. After installing the heat sink, the miner observed a 25% improvement in hash rates and a noticeable drop in operating temperatures. The miner also reported that the heat sink was easy to install and required no additional modifications to the rig.

Installation Tips for Optimal Performance

- Clean the Surface: Before installation, ensure that the surface of the control board and components is clean and free of dust or debris. This ensures optimal contact with the heat sink.

- Apply Thermal Interface Material: Use a high-quality TIM to enhance heat transfer between the components and the heat sink.

- Secure the Heat Sink: Ensure the heat sink is firmly attached to the control board to maintain consistent thermal contact.

- Monitor Airflow: Position the heat sink in a way that maximizes airflow within the mining rig, enhancing heat dissipation.

Conclusion: A Smart Investment for Long-Term Mining Success

In the competitive world of cryptocurrency mining, every advantage counts. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink offers a practical and cost-effective solution to one of the most pressing challenges in ASIC mining: heat management. By preventing heat-induced performance degradation, it ensures consistent hash rates, extends hardware lifespan, and reduces operating costs. Whether you’re running a large-scale mining farm or a single rig at home, this heat sink is a smart investment that pays dividends in both performance and reliability.

As the demand for efficient mining solutions continues to grow, integrating advanced thermal management tools like this heat sink will be essential for staying ahead in the game. Don’t let heat hold back your mining potential—equip your ASIC miners with the right tools to thrive in the heat of competition.