What are the benefits of using aluminum alloy heat sinks in ASIC mining?

August 6, 2025

The Critical Advantages of Aluminum Alloy Heat Sinks in ASIC Mining Operations

Introduction: Why Thermal Management Matters in Cryptocurrency Mining

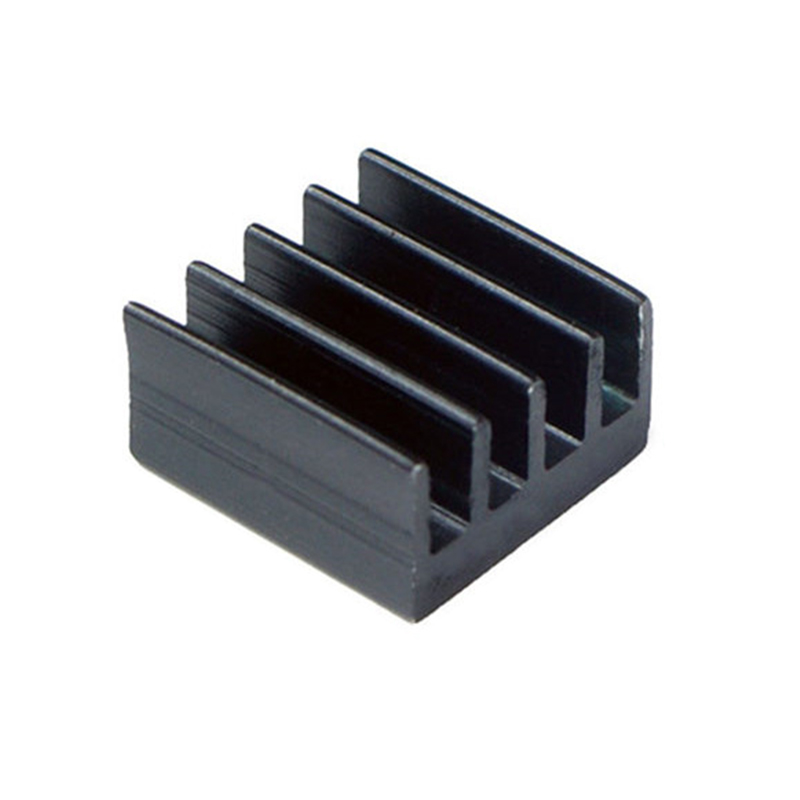

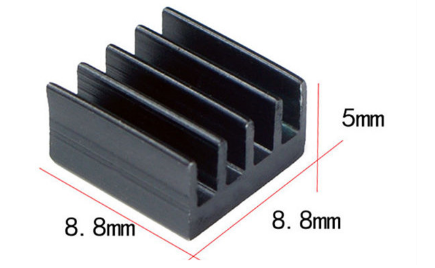

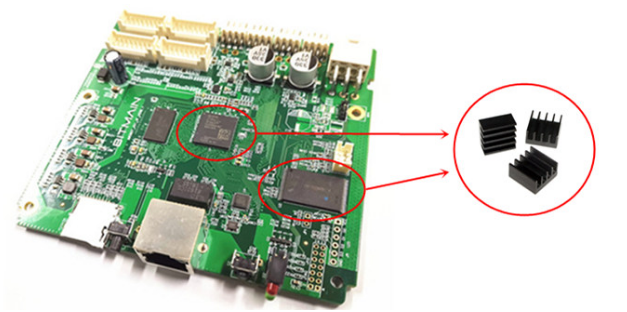

In the high-stakes world of ASIC mining, where every watt of power and every degree of temperature impacts profitability, thermal management isn’t just an engineering consideration—it’s an economic imperative. The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink has emerged as a game-changing solution for control board and chip cooling, specifically designed to meet the rigorous demands of 24/7 mining operations.

Unlike generic cooling solutions, these specialized heat sinks address the unique thermal challenges of cryptocurrency mining rigs, where sustained high-load operations push hardware to its limits. By examining their design advantages and real-world performance benefits, we can understand why professional mining operations increasingly standardize on these aluminum alloy solutions.

The Thermal Science Behind ASIC Miner Cooling

1. Material Matters: Why Aluminum Alloy Outperforms

Aluminum alloy stands as the material of choice for high-performance mining heat sinks due to its exceptional thermal conductivity (approximately 200-250 W/m·K)—nearly five times greater than stainless steel. But conductivity alone doesn’t tell the whole story. Modern mining heat sinks use aerospace-grade aluminum alloys specifically formulated to:

- Maximize heat transfer through optimized crystalline structures

- Resist oxidation that can degrade performance over time

- Maintain structural integrity during thermal cycling (critical for mining rigs that undergo daily temperature fluctuations)

The multi-piece construction of advanced models creates additional surface area for heat dissipation while preventing the “heat saturation” common in solid-block designs.

2. Precision Engineering for Mining-Specific Demands

The compact 8.8mm × 8.8mm × 5mm dimensions represent a carefully calculated balance between:

- Spatial constraints in densely packed mining rigs

- Thermal mass requirements to absorb heat spikes

- Airflow considerations in various rack configurations

Unlike generic heat sinks, these are purpose-built for ASIC control boards where components like power MOSFETs and controller chips generate concentrated heat zones. The precisely machined base ensures perfect contact with chip surfaces when paired with proper thermal interface materials (TIM).

Operational Advantages That Impact Mining Profitability

1. Hash Rate Stability Through Thermal Control

Every 10°C reduction in operating temperature can improve ASIC performance by 2-5% by preventing thermal throttling. Quality aluminum heat sinks maintain components like:

- PWM controllers within optimal 60-80°C range (vs. 90-100°C in poorly cooled setups)

- Voltage regulators at stable temperatures to ensure consistent power delivery

- Memory interfaces cooled to reduce error rates

Real-world case studies show mining farms reducing rejected shares by up to 30% after upgrading to properly engineered aluminum heat sinks.

2. Hardware Longevity: Protecting Your Capital Investment

Thermal cycling is the primary killer of mining equipment. The aluminum alloy’s:

- Low thermal resistance prevents hot spots

- Rapid heat dissipation minimizes temperature swings

- Corrosion-resistant properties withstand humid mining environments

This translates to demonstrable lifespan extensions—mining operations report 20-40% longer service life from properly cooled ASICs compared to those with inferior cooling solutions.

3. Power Efficiency Gains That Compound Over Time

Effective cooling creates a virtuous cycle:

- Lower temperatures reduce electrical resistance in circuits

- Cooler components demand less voltage for stable operation

- The system draws less power while maintaining hash rates

Data from large-scale mining operations shows 3-8% reductions in power consumption per device when implementing optimized aluminum heat sink solutions—a savings that compounds significantly across hundreds or thousands of units.

Design Innovations in Modern Mining Heat Sinks

1. Multi-Piece Architecture for Enhanced Airflow

Advanced heat sinks employ clever segmentation that:

- Creates turbulence to break up boundary layers of stagnant air

- Channels airflow between fins more effectively

- Allows heat to dissipate from multiple surfaces rather than just the top layer

This explains why a properly designed 5mm-tall aluminum heat sink can outperform taller, bulkier alternatives in mining applications.

2. Thermal Interface Optimization

The best heat sink in the world fails without proper contact. Premium solutions incorporate:

- Machined flatness within 0.05mm tolerance for perfect chip contact

- Surface treatments that enhance TIM adhesion

- Pressure-optimized designs that account for mounting force limitations on PCBs

These features ensure the thermal interface material (whether paste, pad, or phase-change compound) works at maximum efficiency.

Implementation Best Practices for Mining Operators

1. Proper Installation Techniques

- Surface preparation: Clean chips with 99% isopropyl alcohol

- TIM application: Use rice-grain sized dots for small chips

- Mounting pressure: Evenly distribute force to avoid PCB warping

2. Maintenance Considerations

- Dust management: Compressed air cleaning every 3-6 months

- TIM replacement: Annual reapplication for peak performance

- Inspection points: Check for oxidation or physical damage during maintenance cycles

Cost-Benefit Analysis for Mining Operations

While aluminum alloy heat sinks carry a modest premium over inferior alternatives, their ROI becomes clear when examining:

- Reduced downtime from thermal-related failures

- Lower power costs per MH/s of mining output

- Extended hardware lifespan delaying capital expenditures

For a medium-sized mining farm (100 ASICs), the annual savings from improved cooling often exceeds $15,000—making the upgrade pay for itself within months.

Future Developments in Mining Thermal Management

Emerging innovations include:

- Graphene-enhanced aluminum composites for 20% better conductivity

- Phase-change integrated heat sinks that adapt to load variations

- Smart heat sinks with embedded temperature sensors for monitoring

These advancements will further cement aluminum alloy’s position as the material of choice for professional mining operations.

Conclusion: Cooling as a Competitive Advantage

In an industry where operational efficiency determines profitability, aluminum alloy heat sinks represent one of the most cost-effective upgrades available to mining operators. Their ability to stabilize hash rates, reduce power consumption, and extend hardware lifespan makes them indispensable tools for professional mining operations.

As mining difficulty increases and margins tighten, the operators who will thrive are those who recognize that effective thermal management isn’t just about keeping equipment cool—it’s about keeping their business competitive in an increasingly challenging market. The precision-engineered aluminum heat sink, though small in size, plays an outsized role in achieving that goal.