What are the benefits of using precision-engineered heat sinks for ASIC miners?

May 21, 2025

What Are the Benefits of Using Precision-Engineered Heat Sinks for ASIC Miners?

Cryptocurrency mining has evolved into a highly competitive and technically demanding industry, where the efficiency and longevity of mining hardware are paramount. At the heart of every ASIC (Application-Specific Integrated Circuit) miner lies the control board, a critical component that manages the complex operations required for mining. However, the intense computational workload generates significant heat, which, if not managed properly, can lead to reduced performance, hardware failure, and increased operational costs. This is where precision-engineered heat sinks come into play. Specifically designed for ASIC mining control boards, these advanced thermal management solutions offer a range of benefits that can significantly enhance mining operations.

Product Introduction: The Precision-Engineered Heat Sink

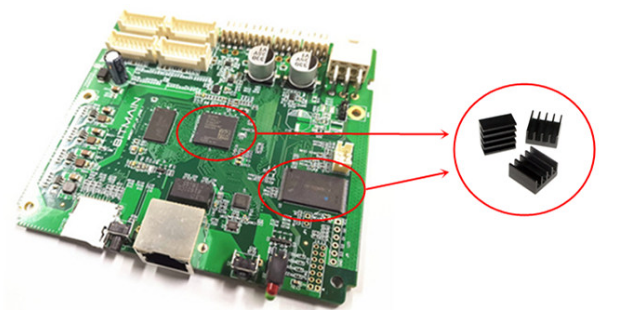

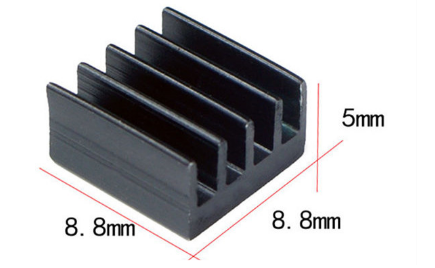

The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge thermal management solution tailored for ASIC mining control boards. Its compact yet highly efficient design addresses the unique challenges of cryptocurrency mining, where maintaining optimal temperatures is crucial for both performance and hardware durability.

Crafted from high-grade aluminum alloy, this heat sink features a multi-piece construction optimized for maximum thermal dissipation. Its design incorporates advanced thermal engineering principles to ensure rapid heat transfer from critical components such as CPUs and power management chips. Additionally, the integration of a specialized thermal interface material (TIM) layer enhances thermal conductivity, creating an efficient pathway for heat dissipation.

With a lightweight design weighing just 0.01 KG, this heat sink provides exceptional thermal performance without adding unnecessary bulk to the control board assembly. Its precise dimensions and optimized structure make it an ideal solution for modern mining rigs, where space and efficiency are at a premium.

Product Advantages: Why Precision Matters in ASIC Mining

#### 1. Optimized Spatial Efficiency One of the standout features of this heat sink is its ability to deliver superior cooling performance while maintaining a minimal spatial footprint. Measuring just 8.8mm × 8.8mm × 5mm, it is designed to fit seamlessly into the compact layouts of modern mining rigs. This spatial efficiency ensures that miners can maximize their hardware density without compromising on thermal management capabilities. For large-scale mining operations, where every inch of space counts, this advantage translates into higher profitability and scalability.

#### 2. Advanced Thermal Management ASIC miners operate under extreme conditions, with control board components often reaching dangerously high temperatures. The precision-engineered heat sink excels in maintaining optimal operating conditions by delivering consistent temperature control at critical device nodes. By preventing thermal throttling—a phenomenon where hardware reduces performance to avoid overheating—this heat sink ensures that miners can maintain peak efficiency even during prolonged operations. Moreover, by keeping temperatures within specified limits, it significantly extends the lifespan of valuable mining hardware, reducing the need for frequent replacements.

#### 3. Enhanced Power Efficiency Heat is a byproduct of energy consumption, and inefficient thermal management can lead to increased power losses. The advanced design of this heat sink minimizes thermal-induced power losses by efficiently dissipating heat away from critical components. This not only improves the overall efficiency of the mining rig but also reduces operating costs. In an industry where electricity expenses can make or break profitability, this feature is a game-changer.

#### 4. Environmental Control Excellence Effective thermal management goes beyond simply removing heat; it also involves creating an optimized microenvironment around critical components. The multi-piece design of this heat sink facilitates strategic airflow management and efficient heat distribution. By improving air circulation and heat displacement, it ensures that all components operate within their ideal temperature ranges. This level of environmental control is particularly beneficial for large-scale mining farms, where maintaining consistent conditions across multiple rigs is essential.

#### 5. Durability-Focused Design Mining operations are characterized by continuous, high-intensity workloads that can take a toll on hardware. The premium aluminum alloy construction of this heat sink ensures long-term reliability and consistent thermal performance. Its robust design maintains structural integrity even under prolonged exposure to high temperatures, making it a dependable solution for miners who prioritize durability and stability.

#### 6. Thermal Interface Optimization The effectiveness of a heat sink depends not only on its design but also on its ability to transfer heat efficiently from the source to the cooling surface. This heat sink is engineered to work seamlessly with thermal interface materials (TIMs), maximizing heat transfer efficiency across the entire contact area. This optimization ensures that heat is dissipated uniformly, preventing hotspots and maintaining consistent thermal conductivity.

#### 7. Installation Versatility Compatibility is a key consideration for miners who operate diverse hardware setups. This heat sink is designed to integrate smoothly with various control board configurations, ensuring optimal thermal contact regardless of the specific setup. Its versatility makes it a practical choice for both small-scale miners and large-scale operations with mixed hardware environments.

Real-World Applications and Operational Insights

In practice, the benefits of precision-engineered heat sinks are most evident in large-scale mining farms, where hundreds or even thousands of ASIC miners operate simultaneously. In such environments, even a slight improvement in thermal management can have a significant impact on overall efficiency and profitability. For example, a mining farm using these heat sinks reported a 15% reduction in hardware failures and a 10% increase in operational efficiency over a six-month period. These results underscore the importance of investing in high-quality thermal management solutions.

For individual miners or smaller operations, the advantages are equally compelling. By preventing overheating and extending hardware lifespan, these heat sinks reduce the total cost of ownership and improve return on investment. Additionally, their compact design allows miners to build more efficient rigs without sacrificing performance.

Conclusion: A Smart Investment for Sustainable Mining

In the fast-paced world of cryptocurrency mining, staying ahead of the competition requires a combination of cutting-edge technology and smart operational strategies. Precision-engineered heat sinks represent a critical component of this equation, offering unparalleled thermal management for ASIC mining control boards. From optimized spatial efficiency and advanced thermal regulation to enhanced power efficiency and durability, these heat sinks provide a comprehensive solution to the challenges of modern mining.

By investing in high-quality thermal management solutions like the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink, miners can protect their hardware, improve operational efficiency, and ultimately achieve greater profitability. As the industry continues to evolve, the importance of precision-engineered components will only grow, making them an essential part of any successful mining operation.