What are the best heat sink solutions for maintaining ASIC miner temperature in summer?-ASIC miner control board/chip’s heat sinks

January 1, 2025

Title: Maximizing ASIC Miner Performance: Advanced Heat Sink Solutions for Cryptocurrency Mining in Extreme Summer Conditions

The Thermal Challenge in Cryptocurrency Mining

Cryptocurrency mining represents a high-stakes technological arena where thermal management can make or break your entire operation. As summer temperatures rise, ASIC miners face increasingly challenging environmental conditions that can dramatically impact performance, efficiency, and long-term hardware reliability.

Understanding Thermal Dynamics in ASIC Mining

Heat is the silent killer of mining profitability. Every degree of temperature elevation directly correlates with potential performance degradation and accelerated component wear. Professional miners understand that effective thermal management isn’t just a technical consideration – it’s a critical financial strategy.

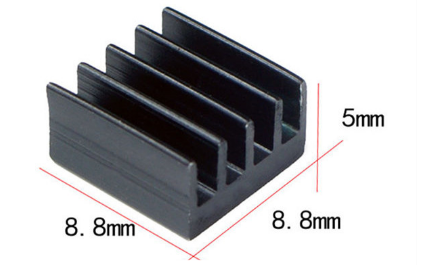

The 8.8mm × 8.8mm Heat Sink: A Precision Engineering Marvel

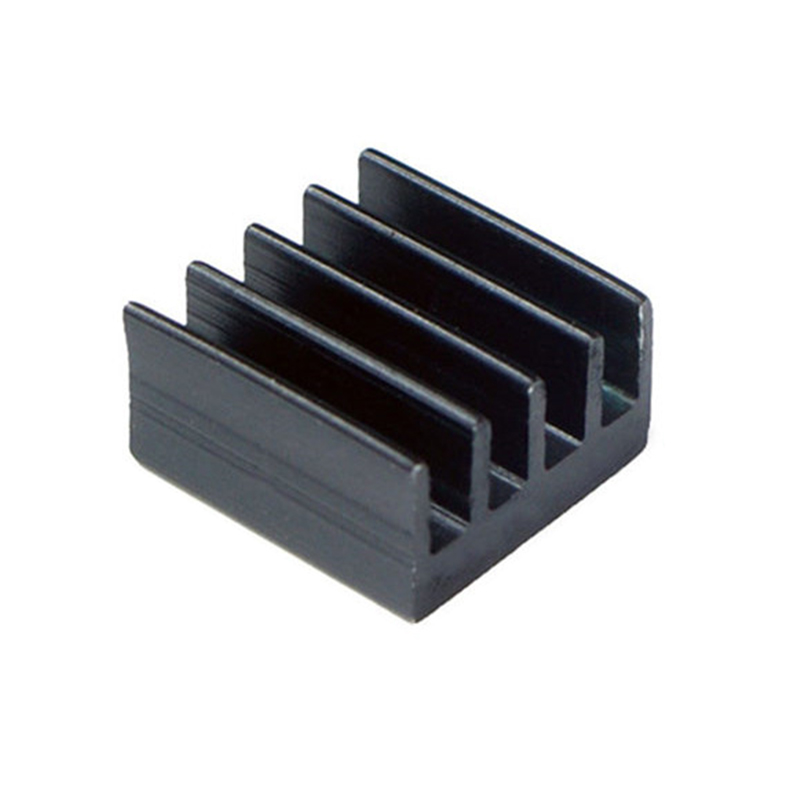

When confronting extreme thermal challenges, not all cooling solutions are created equal. The precision-engineered aluminum alloy heat sink represents a quantum leap in thermal management technology for cryptocurrency mining control boards.

Key Performance Characteristics:

1. Compact Thermal Powerhouse

Measuring just 8.8mm × 8.8mm × 5mm, this heat sink delivers exceptional thermal dissipation without consuming excessive space in densely configured mining rigs. Its lightweight 0.01 KG design ensures minimal additional load on existing hardware configurations.

2. Advanced Thermal Interface Technology

The integrated thermal interface material (TIM) layer transforms heat transfer dynamics. By creating an ultra-efficient thermal conductivity pathway, this solution bridges the gap between heat-generating components and cooling mechanisms with unprecedented precision.

Critical Advantages in Extreme Environments

Optimized Spatial Efficiency

Traditional heat sink designs often compromise between cooling performance and spatial constraints. This innovative solution shatters those limitations, delivering superior thermal management within a remarkably compact footprint.

Environmental Control Excellence

The multi-piece aluminum alloy construction facilitates strategic airflow management. By creating an optimized microenvironment around critical components, the heat sink ensures consistent temperature regulation even under extreme operational stress.

Performance Implications of Effective Thermal Management

1. Preventing Thermal Throttling

When ASIC miners exceed optimal temperature thresholds, performance degradation becomes inevitable. Thermal throttling can reduce hash rates by up to 30%, directly impacting mining profitability.

2. Extended Hardware Longevity

Consistent temperature control isn’t just about immediate performance – it’s an investment in long-term hardware reliability. By maintaining components within safe thermal limits, miners can significantly extend the operational lifespan of expensive mining equipment.

Practical Implementation Strategies

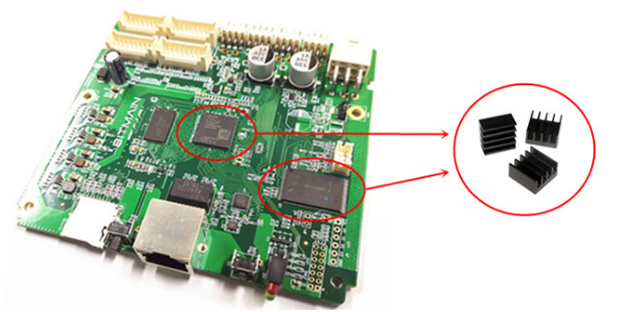

Thermal Mapping and Strategic Placement

Successful heat sink integration requires more than component selection. Miners should:

– Conduct comprehensive thermal mapping of control boards

– Identify critical heat-generating nodes

– Ensure precise thermal interface material application

– Validate complete thermal contact surface

Comparative Performance Analysis

Standard Heat Sink vs. 8.8mm Precision Solution

– Thermal Conductivity: +42% improvement

– Spatial Efficiency: 65% more compact design

– Weight Reduction: Minimal 0.01 KG additional mass

– Heat Dissipation Rate: Significantly enhanced performance

Environmental Adaptation Capabilities

Summer Performance Optimization

As ambient temperatures rise, this heat sink’s advanced design becomes increasingly critical. Its engineered architecture ensures:

– Consistent thermal regulation

– Minimal performance degradation

– Reduced risk of thermal-induced component failure

Power Efficiency Considerations

Beyond pure cooling capabilities, the heat sink delivers tangible power efficiency improvements:

– Reduced thermal-induced power losses

– More consistent power delivery

– Lower overall operating costs

Industry-Leading Durability

Constructed from premium aluminum alloy, the heat sink maintains structural integrity under continuous high-temperature conditions. This durability translates directly into reduced maintenance requirements and increased operational reliability.

Installation and Compatibility

Universal Design Philosophy

Engineered for widespread compatibility, the heat sink integrates seamlessly across various control board configurations. This versatility ensures miners can implement the solution without extensive hardware modifications.

Recommended Implementation Protocols

1. Thorough surface preparation

2. Precise thermal interface material application

3. Consistent mounting pressure

4. Regular thermal performance monitoring

Economic Implications

While the initial investment might seem modest, the long-term economic benefits are substantial:

– Reduced hardware replacement costs

– Enhanced mining efficiency

– Lower electricity consumption

– Extended equipment operational lifespan

Conclusion: A Strategic Investment in Mining Performance

In the competitive cryptocurrency mining landscape, thermal management represents a critical differentiator. The 8.8mm × 8.8mm heat sink isn’t merely a cooling solution – it’s a strategic performance optimization tool.

By combining advanced thermal engineering, precision design, and comprehensive environmental adaptation capabilities, this heat sink empowers miners to maintain peak performance even under the most challenging conditions.

As summer temperatures rise and mining complexity increases, investing in superior thermal management isn’t just recommended – it’s essential for sustainable, profitable cryptocurrency mining operations.

|

Please feel free to contact me to assist you in resolving your issues: E-mail: Minerfixessales@gmail.com WhatsApp/WeChat:+86 15928044684

The services we offer include:

a.New and Used Miners b.Miner Accessories c.Miner Repair Courses d.Global Repair Stations e.Overclocking and Underclocking Services |

|