What are the best heat sink solutions for maintaining ASIC miner temperature in summer?

August 11, 2025

What Are the Best Heat Sink Solutions for Maintaining ASIC Miner Temperature in Summer?

As cryptocurrency mining continues to grow in popularity and complexity, the demand for efficient and reliable thermal management solutions has become more critical than ever. ASIC (Application-Specific Integrated Circuit) miners, the workhorses of modern crypto mining, generate substantial heat during operation. In the sweltering summer months, maintaining optimal temperatures becomes a significant challenge, as excessive heat can lead to reduced performance, hardware degradation, and even catastrophic failures.

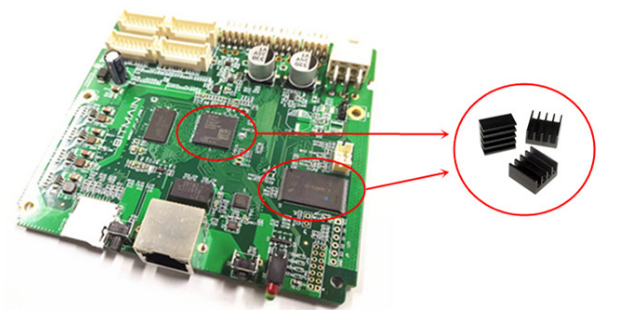

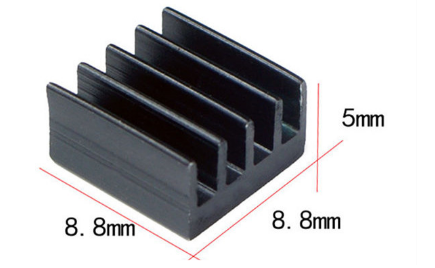

This article explores one of the most effective heat sink solutions designed specifically for ASIC miner control boards: the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink. We’ll delve into its design, advantages, and practical applications, offering mining operators actionable insights to enhance their operations during the hottest seasons.

The Importance of Thermal Management in ASIC Mining

Before diving into the specifics of this heat sink solution, it’s essential to understand why thermal management is so crucial for ASIC miners. ASIC chips are designed to perform highly specialized tasks at maximum efficiency, but this efficiency comes at a cost: heat generation. When temperatures rise beyond optimal levels, several issues can arise:

- Thermal Throttling: To prevent overheating, ASIC miners may reduce their processing power, directly impacting hash rates and profitability.

- Component Degradation: Prolonged exposure to high temperatures can shorten the lifespan of critical components, leading to costly repairs or replacements.

- System Failures: In extreme cases, overheating can cause permanent damage, resulting in downtime and lost revenue.

Effective thermal management ensures that ASIC miners operate within safe temperature ranges, maximizing performance and longevity.

Introducing the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a cutting-edge cooling solution designed specifically for ASIC miner control boards. Its compact yet highly efficient design addresses the unique thermal challenges faced by mining operators, particularly during summer months when ambient temperatures are higher. Let’s explore its key features and benefits.

Technical Architecture

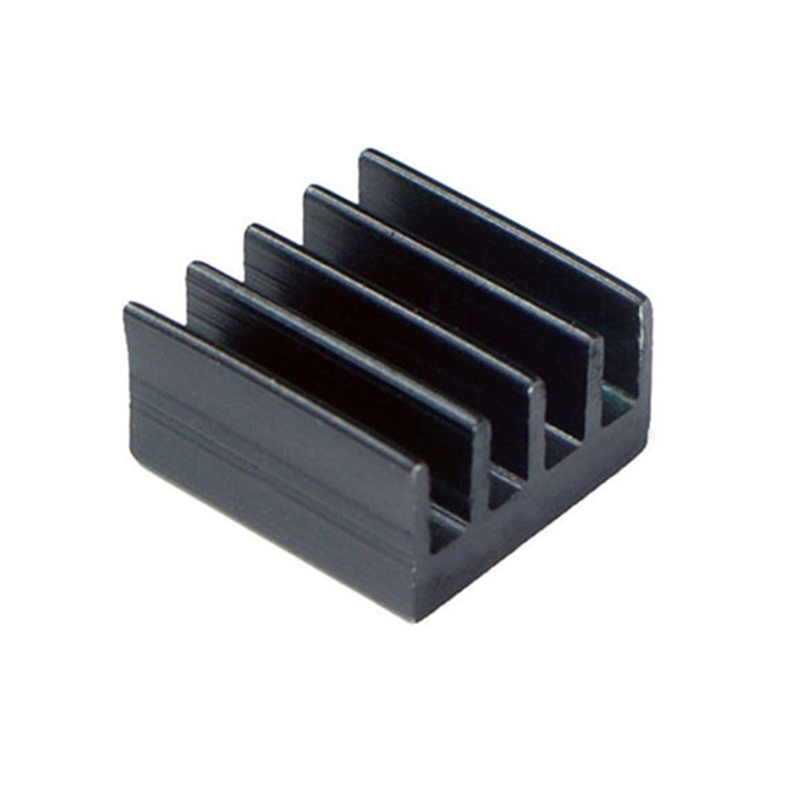

Crafted from high-grade aluminum alloy, this heat sink boasts an optimized multi-piece construction that maximizes thermal dissipation efficiency. Its design incorporates advanced thermal engineering principles to facilitate rapid heat transfer from critical components, such as CPUs and power management chips. The result is a cooling solution that effectively mitigates heat buildup, even under heavy workloads.

Thermal Interface Integration

One of the standout features of this heat sink is its integration with specialized thermal interface materials (TIM). A thermally conductive silica gel layer ensures optimal thermal conductivity between the heat-generating components and the heat sink surface. This interface creates an efficient pathway for heat dissipation, enhancing the overall cooling performance.

Performance Characteristics

Despite its compact form factor, this heat sink delivers exceptional thermal performance. Measuring just 8.8mm × 8.8mm × 5mm and weighing a mere 0.01 KG, it provides optimal thermal management without adding significant mass to the control board assembly. This lightweight design is particularly advantageous for mining rigs, where space and weight constraints are common.

Advantages of the 8.8mm × 8.8mm × 5mm Aluminum Alloy Heat Sink

This heat sink solution offers several distinct advantages that make it an ideal choice for ASIC miner control boards, especially in summer conditions:

Optimized Spatial Efficiency

The heat sink’s precise dimensional specifications ensure maximum cooling performance while minimizing its spatial footprint. This balance allows mining operators to optimize the use of available space within their rigs without compromising on thermal management capabilities.

Advanced Thermal Management

By delivering superior temperature control at critical device nodes, this heat sink maintains optimal operating conditions well within specified thermal limits. This precise regulation helps prevent thermal throttling and extends the lifespan of ASIC components.

Enhanced Power Efficiency

Efficient heat dissipation significantly reduces thermal-induced power losses, improving overall system efficiency and lowering operating costs. The optimized design also helps maintain consistent power delivery to critical mining components, ensuring stable performance.

Environmental Control Excellence

The heat sink’s multi-piece design facilitates strategic airflow management and efficient heat distribution. By creating an optimized microenvironment around critical components, it enhances air circulation and heat displacement, further improving cooling efficiency.

Durability-Focused Design

Constructed from premium aluminum alloy, this heat sink ensures long-term reliability and consistent thermal performance. Its robust design maintains structural integrity even under continuous high-temperature conditions, making it a durable solution for extended mining operations.

Thermal Interface Optimization

Engineered to work seamlessly with thermal interface materials, this heat sink maximizes heat transfer efficiency from components to its surface. This optimization ensures consistent thermal conductivity across the entire contact area, enhancing cooling effectiveness.

Installation Versatility

Designed for compatibility with various control board configurations, this heat sink maintains optimal thermal contact across different mining hardware setups. Its versatility makes it a practical solution for a wide range of ASIC miners.

Practical Applications for Summer Mining Operations

In the context of summer mining operations, the 8.8mm × 8.8mm × 5mm aluminum alloy heat sink provides tangible benefits. Here are some real-world scenarios where this solution excels:

- High Ambient Temperatures: In regions with scorching summers, ambient temperatures can exacerbate heat buildup in mining rigs. This heat sink’s efficient thermal dissipation ensures that ASIC miners remain within safe operating temperatures, even in challenging environments.

- Compact Mining Setups: For operators with space-constrained setups, the heat sink’s compact design allows for effective cooling without requiring additional space or complex modifications.

- Extended Operation Cycles: Mining operations often run 24/7, placing continuous stress on hardware. The heat sink’s durability-focused design ensures reliable performance over extended periods, reducing the risk of downtime.

- Cost-Effective Cooling: By improving power efficiency and reducing thermal-induced losses, this heat sink helps lower operational costs, making it a cost-effective solution for long-term mining operations.

Conclusion

As summer temperatures rise, the need for effective thermal management in ASIC mining becomes paramount. The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink stands out as a superior solution, offering advanced thermal management, optimized spatial efficiency, and long-term durability. Its ability to maintain optimal operating temperatures ensures consistent performance and protects valuable mining hardware from heat-related issues.

For mining operators seeking to enhance their summer operations, investing in this heat sink solution is a practical and cost-effective decision. By addressing the unique thermal challenges of ASIC mining, it not only improves performance but also extends the lifespan of critical components, ultimately boosting profitability in the competitive world of cryptocurrency mining.