What are the top-rated heat sinks for mining control boards in 2024?

February 15, 2025

What Are the Top-Rated Heat Sinks for Mining Control Boards in 2024?

Cryptocurrency mining has evolved significantly over the years, with ASIC (Application-Specific Integrated Circuit) miners becoming the backbone of modern mining operations. As the demand for efficient and reliable mining hardware continues to grow, so does the need for effective thermal management solutions. One of the most critical components in ensuring the longevity and performance of ASIC miners is the heat sink, particularly for the control boards that manage the intricate operations of these powerful machines. In this article, we’ll explore the top-rated heat sinks for mining control boards in 2024, focusing on their design, advantages, and real-world applications.

Product Introduction: The Precision-Engineered Aluminum Alloy Heat Sink

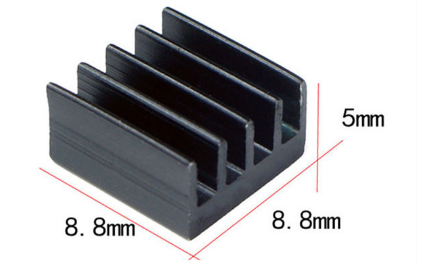

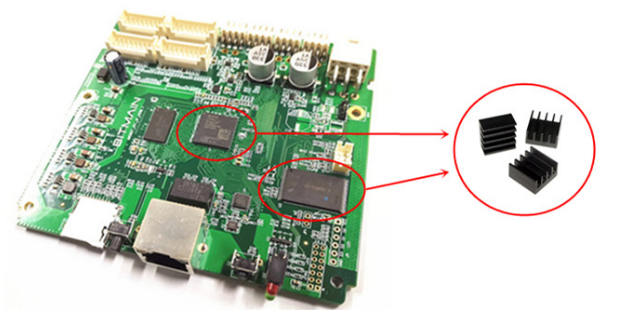

At the forefront of thermal management for ASIC mining control boards is the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink. This compact yet highly efficient cooling solution is specifically designed to meet the rigorous demands of cryptocurrency mining environments. With its advanced thermal engineering and durable construction, this heat sink ensures that mining control boards operate at optimal temperatures, even under continuous high-load conditions.

Technical Architecture

The heat sink is crafted from high-grade aluminum alloy, a material known for its excellent thermal conductivity and lightweight properties. Its multi-piece construction is optimized to maximize heat dissipation efficiency, particularly for critical components like CPUs and power management chips. The design incorporates advanced thermal engineering principles, ensuring rapid heat transfer away from sensitive areas and maintaining stable operating conditions.

Thermal Interface Integration

A key feature of this heat sink is its integration with specialized thermal interface material (TIM), typically a thermally conductive silica gel. This TIM layer enhances the heat transfer efficiency between the control board components and the heat sink surface, creating a seamless thermal pathway. By ensuring optimal contact and conductivity, the TIM minimizes thermal resistance and maximizes cooling performance.

Performance Characteristics

Despite its compact size (8.8mm × 8.8mm × 5mm), this heat sink delivers exceptional thermal performance. Its lightweight design (just 0.01 kg) ensures it doesn’t add significant mass to the control board assembly, making it ideal for densely packed mining rigs. The heat sink’s precise dimensions and optimized structure make it a perfect fit for modern ASIC miners, where space is often at a premium.

Product Advantages: Why This Heat Sink Stands Out

In the competitive world of cryptocurrency mining, every component must deliver maximum value. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink stands out for several reasons, offering tangible benefits that translate into improved mining efficiency and hardware longevity.

1. Optimized Spatial Efficiency

One of the standout features of this heat sink is its ability to deliver superior cooling performance without occupying excessive space. Mining rigs are often densely packed, and every millimeter counts. The heat sink’s compact design ensures it fits seamlessly into tight configurations, allowing miners to maximize their hardware setup without compromising on thermal management.

2. Advanced Thermal Management

Cryptocurrency mining generates significant heat, and maintaining optimal temperatures is crucial for both performance and hardware lifespan. This heat sink excels at regulating temperatures at critical device nodes, preventing thermal throttling and ensuring consistent operation. By keeping temperatures within specified limits, it helps extend the lifespan of expensive mining components.

3. Enhanced Power Efficiency

Heat is a major contributor to power losses in mining operations. This heat sink’s efficient heat dissipation reduces thermal-induced power losses, translating into improved overall system efficiency. For mining operators, this means lower electricity costs and better returns on investment.

4. Environmental Control Excellence

The heat sink’s multi-piece design facilitates strategic airflow management, creating an optimized microenvironment around critical components. Improved air circulation and heat displacement ensure that mining rigs operate in a balanced thermal environment, reducing the risk of overheating and hardware failure.

5. Durability-Focused Design

Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous mining operations. Its robust design maintains structural integrity even under high-temperature conditions, ensuring long-term reliability and consistent performance.

6. Thermal Interface Optimization

The heat sink is engineered to work seamlessly with thermal interface materials, maximizing heat transfer efficiency. This ensures consistent thermal conductivity across the entire contact area, further enhancing its cooling capabilities.

7. Installation Versatility

Compatibility is key in mining operations, where hardware configurations can vary widely. This heat sink is designed to integrate effortlessly with various control board setups, ensuring optimal thermal contact regardless of the specific hardware being used.

Real-World Applications and Operational Insights

To truly appreciate the value of this heat sink, it’s essential to understand its practical applications in cryptocurrency mining operations. Here are some real-world scenarios where this component makes a significant difference:

Scenario 1: High-Density Mining Farms

In large-scale mining farms, space optimization is critical. The compact design of this heat sink allows miners to pack more hardware into limited spaces without sacrificing cooling performance. Its ability to efficiently dissipate heat ensures that each miner operates at peak efficiency, even in densely configured rigs.

Scenario 2: Continuous Operation

Mining operations often run 24/7, placing immense stress on hardware components. The heat sink’s durability and advanced thermal management ensure that control boards remain cool and functional even during extended periods of high-intensity use. This reduces downtime and maintenance costs, providing a clear operational advantage.

Scenario 3: Cost-Effective Power Management

By minimizing thermal-induced power losses, this heat sink helps reduce electricity consumption, a significant expense in mining operations. Over time, these savings can add up, making the heat sink a cost-effective investment for serious miners.

Conclusion: A Must-Have for Modern Mining Operations

As cryptocurrency mining continues to evolve, so do the demands placed on mining hardware. The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink represents a cutting-edge solution for managing the thermal challenges of ASIC mining control boards. Its optimized design, advanced thermal management, and durable construction make it an indispensable component for anyone serious about maximizing their mining efficiency and hardware lifespan.

Whether you’re running a small-scale operation or managing a large mining farm, investing in high-quality heat sinks like this one can yield significant returns. By ensuring stable temperatures and reducing power losses, this heat sink not only enhances performance but also contributes to the long-term sustainability of your mining operations. In 2024 and beyond, this heat sink is set to remain a top-rated choice for mining operators worldwide.