Why are heat sinks important for maintaining ASIC miner performance over time?

April 23, 2025

Why Are Heat Sinks Important for Maintaining ASIC Miner Performance Over Time?

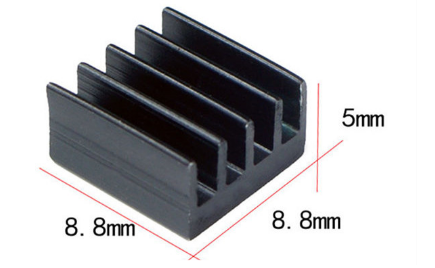

Cryptocurrency mining is an energy-intensive process that relies heavily on the performance and longevity of Application-Specific Integrated Circuit (ASIC) miners. These powerful machines are designed to solve complex cryptographic puzzles, but they generate significant heat during operation. Without proper thermal management, this heat can lead to reduced efficiency, hardware failures, and even permanent damage. This is where heat sinks play a critical role. In this article, we’ll explore the importance of heat sinks in maintaining ASIC miner performance over time, focusing on the precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink designed specifically for ASIC mining control boards.

The Role of Heat Sinks in ASIC Mining

ASIC miners are built to operate at maximum capacity, often running 24/7 in demanding environments. The control board, which houses critical components like CPUs and power management chips, is particularly vulnerable to heat buildup. Excessive heat can cause thermal throttling, where the device reduces its performance to prevent overheating, or worse, lead to component failure.

Heat sinks are essential components that manage this heat by dissipating it away from sensitive parts. By maintaining optimal operating temperatures, heat sinks ensure that ASIC miners perform consistently and reliably over extended periods. They are not just accessories—they are integral to the longevity and efficiency of mining hardware.

Introducing the Precision-Engineered Heat Sink for ASIC Miners

The 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a state-of-the-art thermal management solution designed specifically for ASIC mining control boards. Its compact size and lightweight design make it an ideal choice for modern mining rigs, where space is often at a premium. But what sets this heat sink apart from others? Let’s dive into its technical architecture and features.

Technical Architecture

Crafted from high-grade aluminum alloy, this heat sink is engineered for maximum thermal dissipation efficiency. Its multi-piece construction is optimized using advanced thermal engineering principles to ensure rapid heat transfer from critical components. The design focuses on creating an efficient pathway for heat to move away from the control board’s CPUs and power management chips.

Thermal Interface Integration

One of the standout features of this heat sink is its integration with specialized thermal interface materials (TIMs). A thermally conductive silica gel layer is applied between the heat-generating components and the heat sink surface. This TIM layer enhances thermal conductivity, ensuring that heat is transferred efficiently and evenly across the contact area. The result is a stable and reliable thermal management system that prevents hotspots and maintains consistent temperatures.

Performance Characteristics

Despite its compact size, this heat sink delivers exceptional thermal performance. Its dimensions (8.8mm × 8.8mm × 5mm) and weight (0.01 KG) have been carefully calculated to provide optimal cooling without adding unnecessary bulk to the control board assembly. This makes it a perfect fit for modern mining rigs, where space and weight considerations are critical.

Advantages of Using This Heat Sink in ASIC Mining Operations

The precision-engineered heat sink offers several key advantages that make it an indispensable component for ASIC miners. Here’s how it translates into real-world benefits for mining operators:

Optimized Spatial Efficiency

Modern mining rigs are often packed with hardware, leaving little room for additional components. The compact design of this heat sink maximizes cooling performance without taking up valuable space. Its small footprint allows mining operators to maintain efficient thermal management without compromising the layout of their rigs.

Advanced Thermal Management

This heat sink excels at maintaining optimal operating temperatures for control board components. By preventing thermal throttling and reducing the risk of overheating, it ensures that ASIC miners operate at peak performance. Consistent temperature control also extends the lifespan of critical components, reducing the need for frequent repairs or replacements.

Enhanced Power Efficiency

Efficient heat dissipation directly translates to improved power efficiency. When components operate within their optimal temperature range, they consume less power and generate fewer losses. This not only reduces electricity costs but also enhances the overall efficiency of the mining operation.

Environmental Control Excellence

The multi-piece design of this heat sink facilitates strategic airflow management within the mining rig. By creating an optimized microenvironment around critical components, it ensures that heat is distributed evenly and displaced effectively. This contributes to a more stable and reliable operating environment for the entire rig.

Durability-Focused Design

Constructed from premium aluminum alloy, this heat sink is built to withstand the rigors of continuous mining operations. Its robust design maintains structural integrity even under high-temperature conditions, ensuring consistent performance over time. This durability-focused approach minimizes downtime and maximizes the return on investment for mining operators.

Thermal Interface Optimization

The integration with thermal interface materials (TIMs) is a game-changer for heat transfer efficiency. By ensuring optimal contact between the heat sink and components, it maximizes thermal conductivity and prevents heat buildup. This optimization is crucial for maintaining stable temperatures in high-performance mining rigs.

Installation Versatility

Designed for compatibility with various control board configurations, this heat sink is highly versatile. Whether you’re working with a custom setup or a standard mining rig, it ensures optimal thermal contact and performance. This flexibility makes it a practical choice for a wide range of mining operations.

Real-World Applications and Benefits

To understand the true value of this heat sink, let’s look at a real-world example. Imagine a mining operation with 100 ASIC miners running continuously. Without effective thermal management, each miner could experience a 10% reduction in performance due to thermal throttling. Over time, this adds up to significant lost revenue.

By implementing the precision-engineered heat sink, the operation maintains consistent temperatures, preventing throttling and ensuring full performance. Additionally, the extended lifespan of components reduces maintenance costs and downtime. The result is a more profitable and sustainable mining operation.

Conclusion

In the competitive world of cryptocurrency mining, every advantage counts. The precision-engineered 8.8mm × 8.8mm × 5mm aluminum alloy heat sink is a critical tool for maintaining ASIC miner performance over time. Its advanced thermal management capabilities, compact design, and durability-focused construction make it an essential component for any mining operation.

By investing in high-quality heat sinks, mining operators can protect their hardware, enhance efficiency, and maximize profitability. Whether you’re running a small-scale operation or a large mining farm, this heat sink offers the thermal management solution you need to stay ahead in the game. Don’t let heat hold your mining operation back—embrace the power of precision-engineered heat sinks and ensure long-term success in the world of cryptocurrency mining.